Liquid bromine metering device

A metering device and liquid bromine technology, applied in liquid bottling, packaging, liquid treatment, etc., can solve the problems of liquid bromine leakage, affecting the control level of the bromination device, the quality of brominated products, and the low measurement accuracy of the metering pump. and low running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

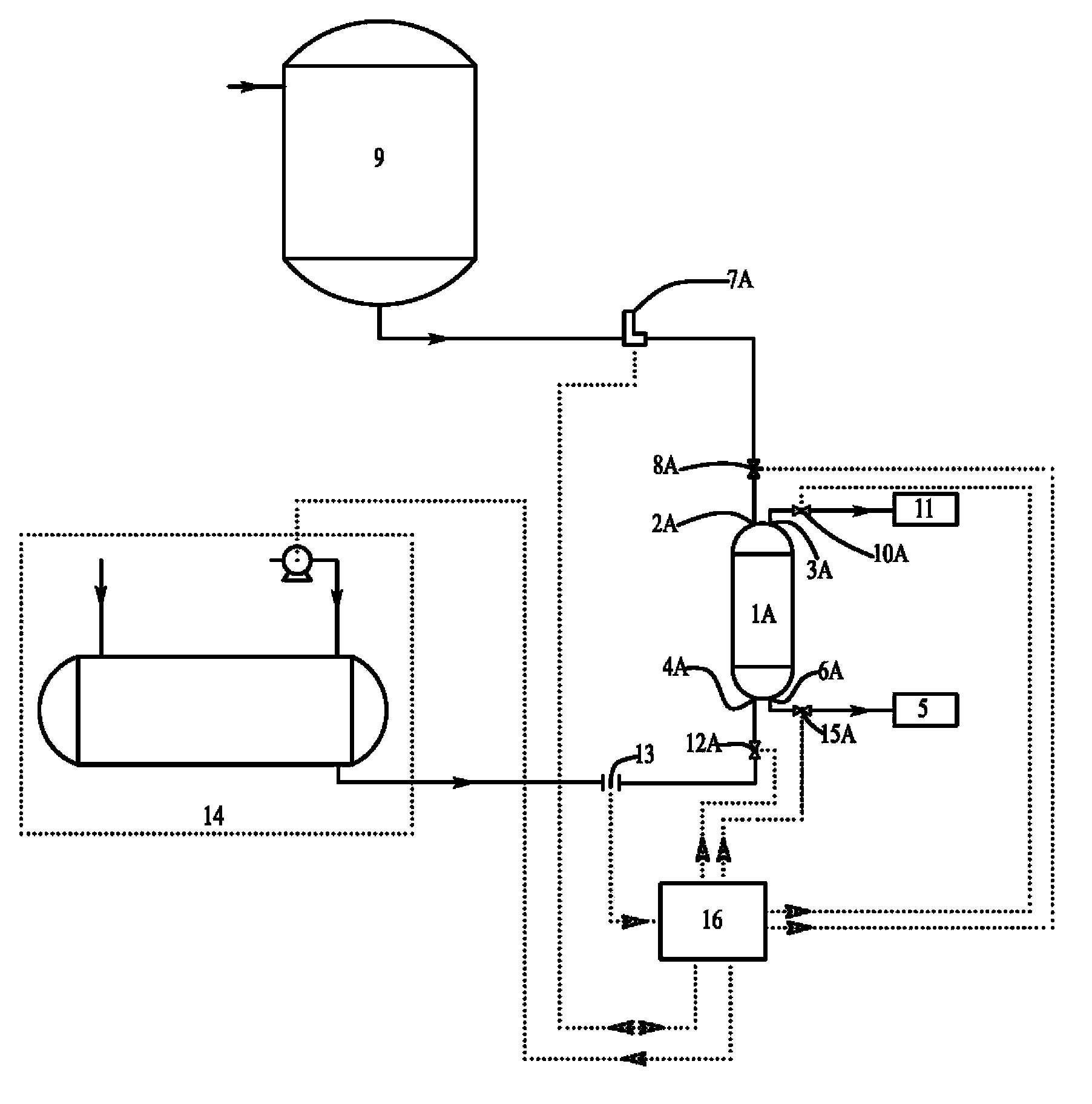

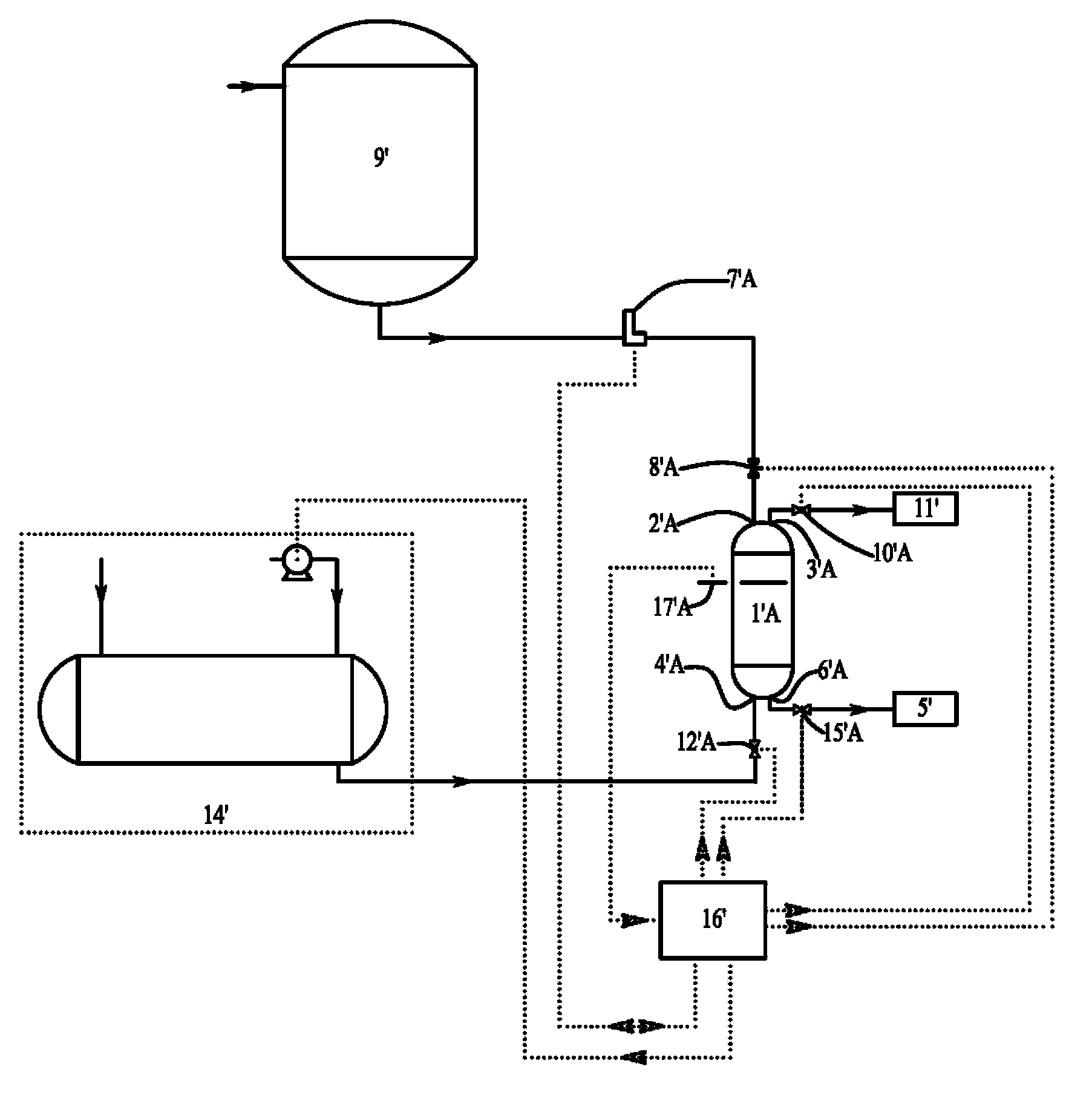

[0093] In this example use figure 1 The shown liquid bromine metering device includes a hollow glass interface partition as an interface partition accessory.

[0094] Cylindrical liquid bromine metering tank 1A is made of stainless steel lined with polytetrafluoroethylene, with a volume of 5m 3 , with an aspect ratio of 5. The hollow glass interface separator is non-magnetic, and its overall density is 1.80kg / L. The metering pump 7A is a plunger pump with a nominal accuracy of ±1%. A flow meter (not shown) is provided between the valve 15A and the bromine demand device 5 to measure the liquid bromine flow and its fluctuation on-line.

[0095] Liquid bromine is injected in the liquid bromine measuring tank 1A with the flow rate of 250kg liquid bromine / hour. When liquid bromine reaches 90% by volume of liquid bromine metering tank 1A, stop injecting liquid bromine in liquid bromine metering tank 1A.

[0096] The distilled water is metered into the liquid bromine metering ta...

Embodiment 2

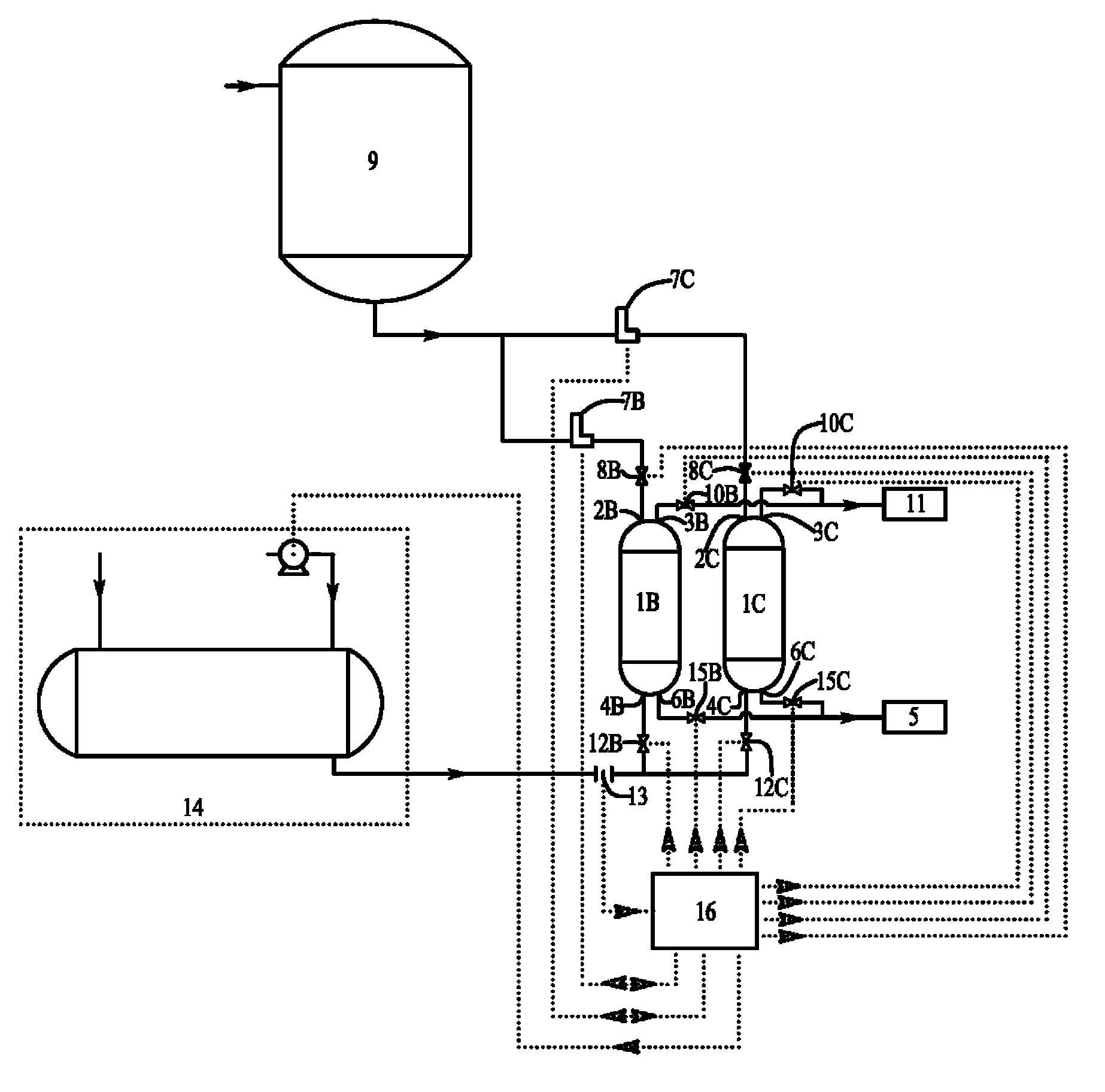

[0099] In this example use figure 2 The liquid bromine metering device shown does not include an interface separation accessory within it.

[0100] Cylindrical liquid bromine measuring tanks 1B and 1C are made of glass-lined stainless steel with a volume of 5m 3 , with an aspect ratio of 2. The metering pumps 7B and 7C are plunger pumps with a nominal accuracy of ±1%. A flow meter (not shown) is provided between the valves 15B, 15C and the bromine demand device 5 to measure the liquid bromine flow and its fluctuation on-line.

[0101] Liquid bromine is injected in the liquid bromine metering tank 1B, 1C with the flow rate of 250kg liquid bromine / hour. When liquid bromine reaches 95% by volume of liquid bromine metering tank 1B, 1C, stop injecting liquid bromine in liquid bromine metering tank 1B, 1C.

[0102] The distilled water is metered into the liquid bromine metering tanks 1B and 1C by metering pumps 7B and 7C at 40.4 kg / h, and thus the liquid bromine is metered into...

Embodiment 3

[0105] In this example use figure 2 The liquid bromine metering device is shown, and includes a Teflon membrane inside as an interface separation accessory.

[0106] Cylindrical liquid bromine metering tanks 1B and 1C are made of Hastelloy (C-276), and the tank body is divided into upper and lower parts. , The PTFE barrel-shaped film that moves freely up and down to the top and bottom of the tank in 1C is used as an interface separation accessory. The volume of liquid bromine metering tank 1B, 1C is 5m 3 , with an aspect ratio of 2. The metering pumps 7B and 7C are plunger pumps with a nominal accuracy of ±1%. A flow meter (not shown) is provided between the valves 15B, 15C and the bromine demand device 5 to measure the liquid bromine flow and its fluctuation on-line.

[0107] Liquid bromine is injected in the liquid bromine metering tank 1B, 1C with the flow rate of 250kg liquid bromine / hour. When liquid bromine reaches 90% by volume of liquid bromine metering tank 1B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com