Low-dose scraper type metering feeding device for dyeing powder auxiliary agent

A technology of feeding device and small dose, which is applied in the direction of mixer with rotating stirring device, transportation, packaging, dissolving, etc. It can solve problems such as inoperability, pipe blockage, large water consumption, etc., and achieve stability and high metering height precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

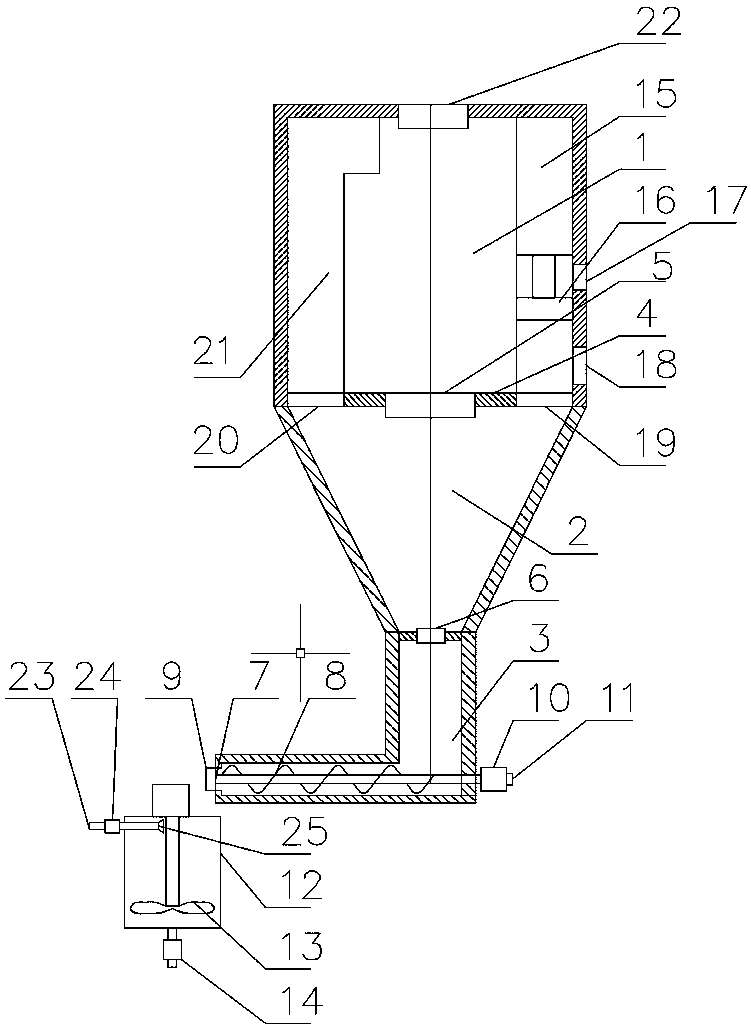

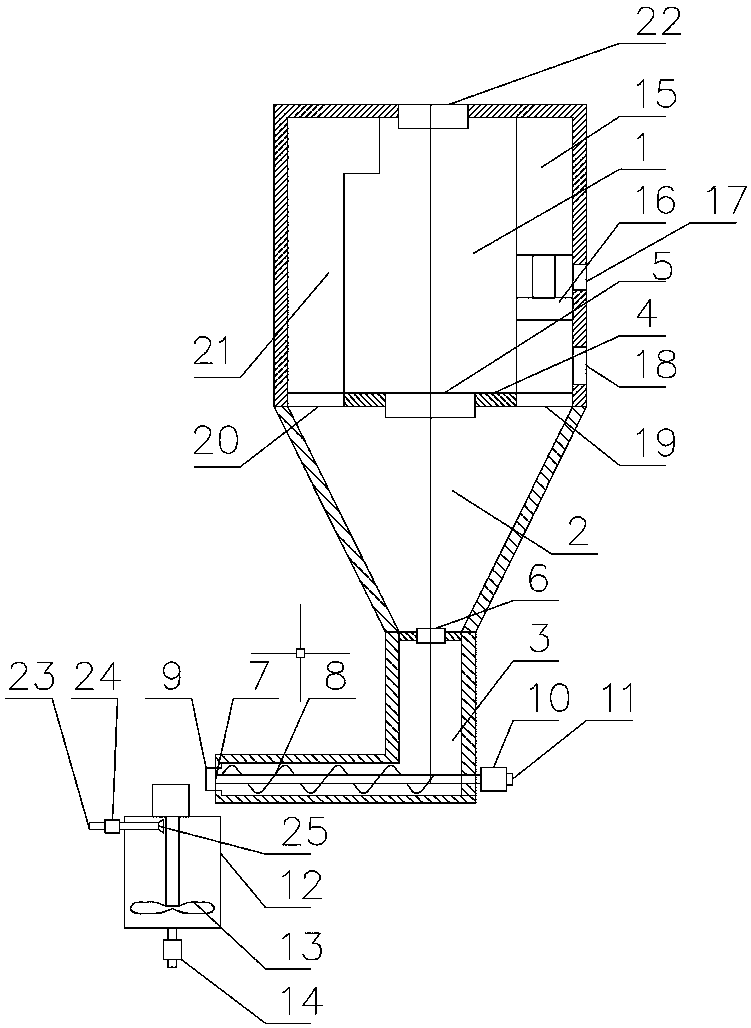

[0019] Such as figure 1 As shown: the small-dose scraper-type metering and feeding device for dyeing powder auxiliaries in this embodiment includes a powder auxiliaries storage bin 1, a conical powder auxiliaries arranged at the lower part of the powder auxiliaries storage bin under normal pressure Replenishment bin 2, L-shaped pipeline bin 3 arranged at the lower part of the conical powder auxiliaries atmospheric pressure refill bin; the partition between the powder auxiliaries storage bin and the powder auxiliaries storage bin 4 is provided with a feeding one-way valve 5, and the upper end of the L-shaped pipeline warehouse is connected to the conical powder additive normal-pressure feeding warehouse through a one-way feeding valve 6, and one of the L-shaped pipeline warehouses The side is provided with a discharge port 7, and the bottom of the L-shaped pipeline is provided with a screw pusher rod 8, and the screw pusher rod is provided with a scraper 9 at the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com