Process for recycling diesel oil in waste oil base drilling fluid

A technology for oil-based drilling fluid and waste drilling fluid, which is applied in the field of diesel recovery technology in waste oil-based drilling fluid, can solve the problem that waste residue and waste fluid cannot be effectively treated, the quality of regenerated diesel oil is difficult to be reused, and waste diesel oil is difficult to be reused. Problems such as poor regeneration effect, to achieve the effect of simple and easy-to-obtain medicine, low production cost, pure color and smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

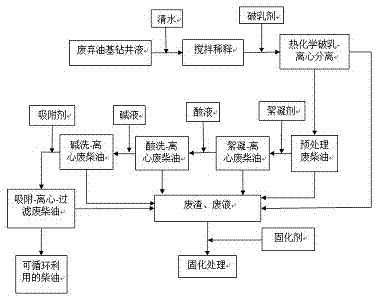

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the recovery process of diesel oil in waste oil-based drilling fluid is characterized in that it includes separating diesel oil from waste drilling fluid and purifying the separated waste diesel oil. The separation of diesel oil from waste drilling fluid includes the following process steps: (1) adding water to dilute waste oil-based drilling fluid; (2) thermochemical demulsification-centrifugal separation of waste oil-based drilling fluid; Purification includes the following process steps: (1) centrifugal pretreatment of waste diesel oil; (2) flocculation-centrifugal treatment of waste diesel oil; (3) pickling-centrifugal treatment of waste diesel oil; (4) alkali washing-centrifugal treatment of waste diesel oil; (5) White clay adsorption-centrifugation-filtration treatment of waste diesel oil.

[0019] The recovery process of diesel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com