Preparation method of paraffin/expanded perlite phase-change thermal insulation mortar

A technology of expanded perlite and thermal insulation mortar is applied in the field of preparation of paraffin/expanded perlite phase change mortar to achieve the effects of reducing building energy consumption, increasing comfort and improving indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

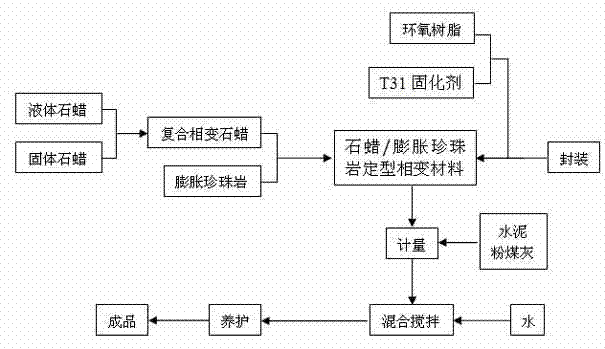

Method used

Image

Examples

Embodiment 1

[0033] Paraffin / expanded perlite phase change thermal insulation mortar:

[0034] 1. Formula (weight ratio):

[0035] Ordinary Portland cement 364 parts

[0036] 40 parts of fly ash

[0037] Expanded perlite 160 parts

[0038] 400 parts of water

[0039] 30 parts epoxy resin

[0040] T31 curing agent 30 parts

[0041] Phase change energy storage materials 320 parts

[0042] 2. Its preparation process is:

[0043] ⑴ Selection of raw materials:

[0044] Ordinary Portland cement is 42.5 ordinary Portland cement produced by Shenyang Jidong Cement Co., Ltd.;

[0045] Fly ash is produced by Shenhai Thermal Power Plant, 350-450 mesh;

[0046] T31 curing agent and epoxy resin are produced by Shenyang Chint Anticorrosion Material Co., Ltd.;

[0047] Solid paraffin and liquid paraffin are produced by the first petrochemical plant of Fushun Petrochemical Company;

[0048] Expanded perlite is produced by Henan Xinyang Xinrun Thermal Insulation Building Materials Co., Ltd., with...

Embodiment 2

[0057] Paraffin / expanded perlite phase change thermal insulation mortar:

[0058] 1. Formula (weight ratio):

[0059] Ordinary Portland cement 364 parts

[0060] 40 parts of fly ash

[0061] Expanded perlite 170 parts

[0062] 440 parts of water

[0063] 35 parts epoxy resin

[0064] T31 curing agent 35 parts

[0065] Phase change energy storage materials 340 parts

[0066] 2. Its preparation process is:

[0067] Its preparation process is identical with embodiment 1.

[0068] The phase-change thermal insulation mortar prepared according to the method of the invention can obviously outperform the prior art in thermal insulation effect, and has the advantages of adjusting temperature to increase comfort, reducing building energy consumption and improving indoor environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com