Thermal gas flow circulating type winnowed coal humidifying process for indirectly utilizing waste gas of coke oven flue

A coke oven flue gas, hot gas flow technology, applied in the direction of separating solids from solids with gas flow, coke oven, furnace type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

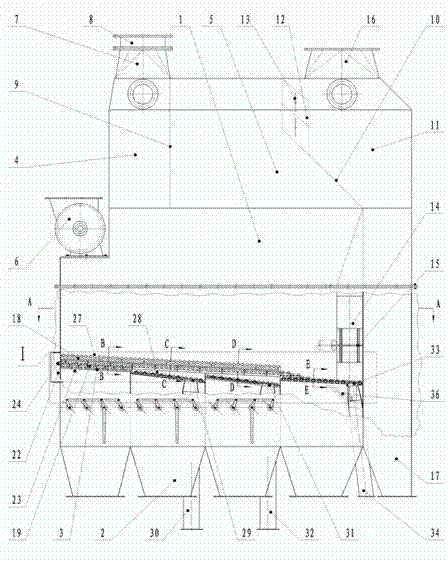

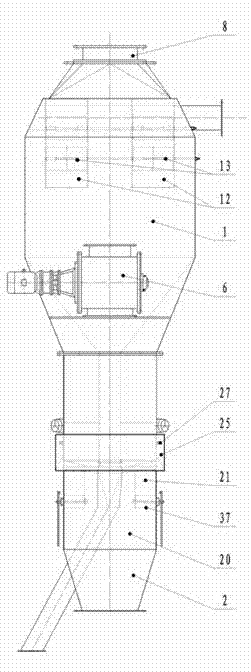

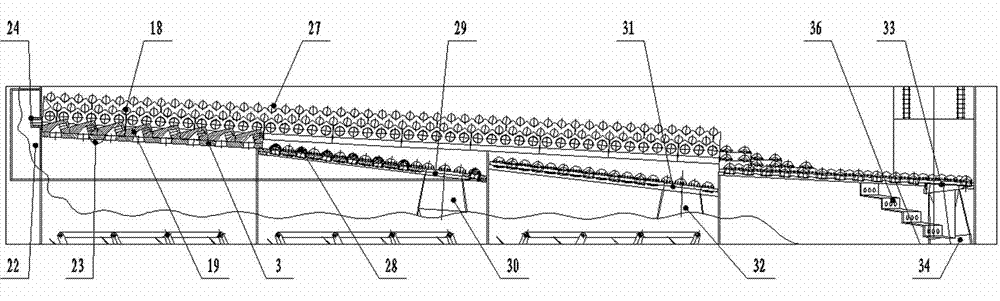

[0043] a kind of like Figure 9 The hot air circulation type air separation coal humidity control process that indirectly utilizes the waste heat of coke oven flue gas is shown. The hot air circulation type air separation coal humidity adjustment process is mainly used in Figure 1 to Figure 8 The full-boiling winnowing drying fluidized bed and hot exhaust gas waste heat utilization system are shown.

[0044] Such as Figure 1 to Figure 8 As shown, the full-boiling air selection and drying fluidized bed 42 that can carry out winnowing and drying simultaneously in this embodiment includes an outer shell 1, four segmented air chambers 2 and air distribution plates 3; the outer shell 1 and the air distribution plates 3 are coated A fluidized bed cavity is formed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com