Process system for utilizing waste heat in coking coal preparation process

A technology of process system and waste heat, applied in the field of process system, achieves the effect of simple operation, simple structure and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

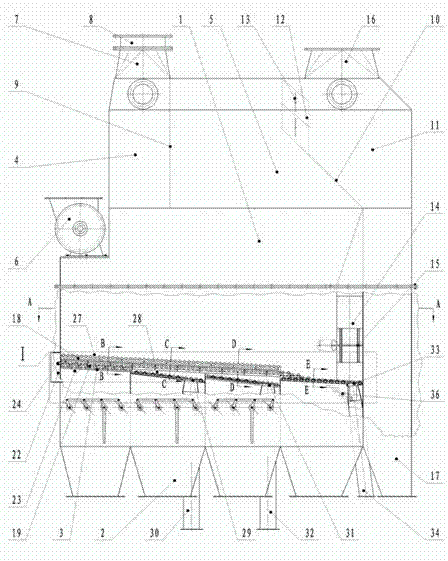

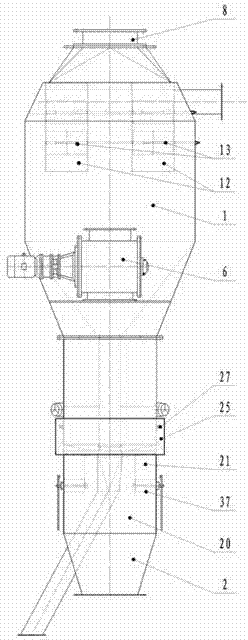

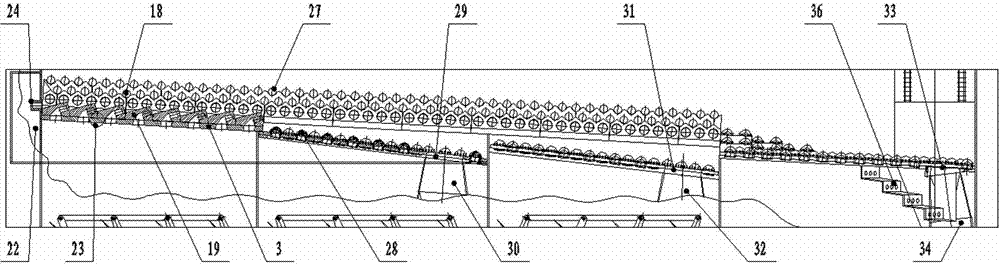

[0042] a kind of like Figure 9 The process system for waste heat utilization in the coking coal preparation process shown, the process system includes such as Figure 1 to Figure 8 Shown is a full-boiling winnowing drying fluidized bed 42 and a waste heat utilization system of hot exhaust gas.

[0043] Such as Figure 1 to Figure 8 As shown, the full-boiling air selection and drying fluidized bed 42 that can carry out winnowing and drying simultaneously in this embodiment includes an outer shell 1, four segmented air chambers 2 and air distribution plates 3; the outer shell 1 and the air distribution plates 3 are coated A fluidized bed cavity is formed. The fluidized bed chamber is mainly composed of a front chamber 4 and a rear chamber 5 , and the front chamber 4 and the rear chamber 5 are separated by a chamber partition 9 . Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com