High-speed double-twisting machine

A two-for-one twister, high-speed technology, used in spinning machines, continuous winding spinning machines, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

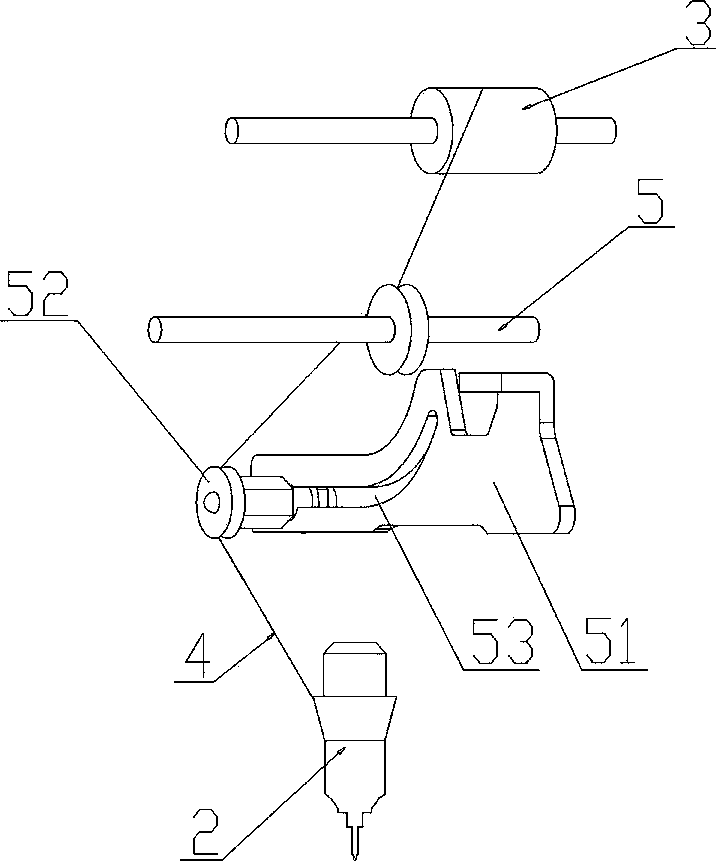

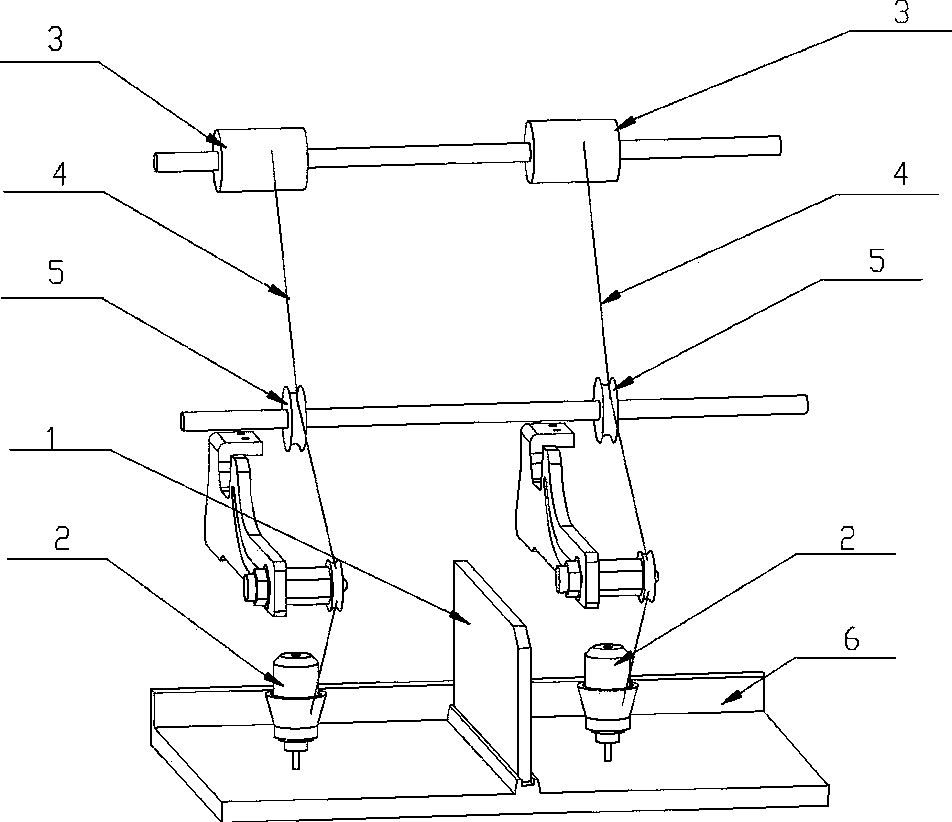

[0015] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a high-speed two-for-one twister, which consists of a frame 6, at least two yarn storage drums 2, a yarn guiding device 5, and a friction roller 3.

[0016] Wherein, the yarn storage drum 2, the yarn guiding device 5 and the friction roller 3 are sequentially installed on the frame 6 from bottom to top. The yarn storage drum 2 is used for twisting the yarn 4 . The rubbing roller 3 is used to wind the twisted yarn 4 . The yarn guiding device 5 is used to guide the yarn, and it includes a tension frame 51 and a guide wheel 52. A chute 53 is arranged on the tension frame 51, and the guide wheel 52 is installed in the chute 53. and can slide continuously along the chute 53, so that the center line of the godet wheel 52 and the yarn storage drum 2 are consistent.

[0017] The guide wheel 52 includes a guide wheel shaft 55 and a rotatable guide wheel 56 mounted on the guide wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com