Polysulfonamide fiber compound rope and manufacturing method thereof

A technology of polysulfone fibers and core-spun ropes, which is applied in the field of ropes, can solve the problems of large heat shrinkage, heat resistance, and poor thermal oxygen aging resistance, and achieve small heat shrinkage, good acid resistance, and good heat resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

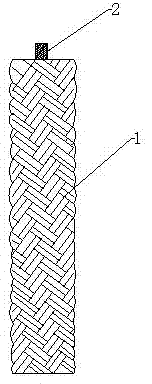

[0013] figure 1 It is a schematic diagram of the polysulfone fiber core-spun rope of the present invention, and this embodiment is specifically described in conjunction with the accompanying drawings. The polysulfone fiber core-spun rope includes a rope sheath 1 and a rope core 2, the rope core 2 is arranged in the rope sheath 1, and the rope The skin 1 is configured as an outer body woven from multiple bundles of sulfonamide fiber strands twisted from a plurality of surface-treated sulfonamide fiber filaments. The rope sheath 1 is a cylinder braided according to the S twist direction of part of the sulfonamide fiber strands and the Z twist direction of the other part of the sulfone fiber strands, and the rope core 2 is set as an aggregate of sulfone fiber fibers. In this embodiment, the rope sheath 1 is set as a cylinder formed by weaving 16 bundles of sulfonamide fiber strands according to 8 strands in the S twist direction and 8 bundles in the Z twist direction.

[0014] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com