Patents

Literature

30results about How to "Tightly woven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contoured buttocks enhancing and tummy slimming hosiery and foundation garment

ActiveUS20150208733A1Control slimming effectAvoiding “ muffin-top ” effectGirdlesCorsetsButtocksYarn

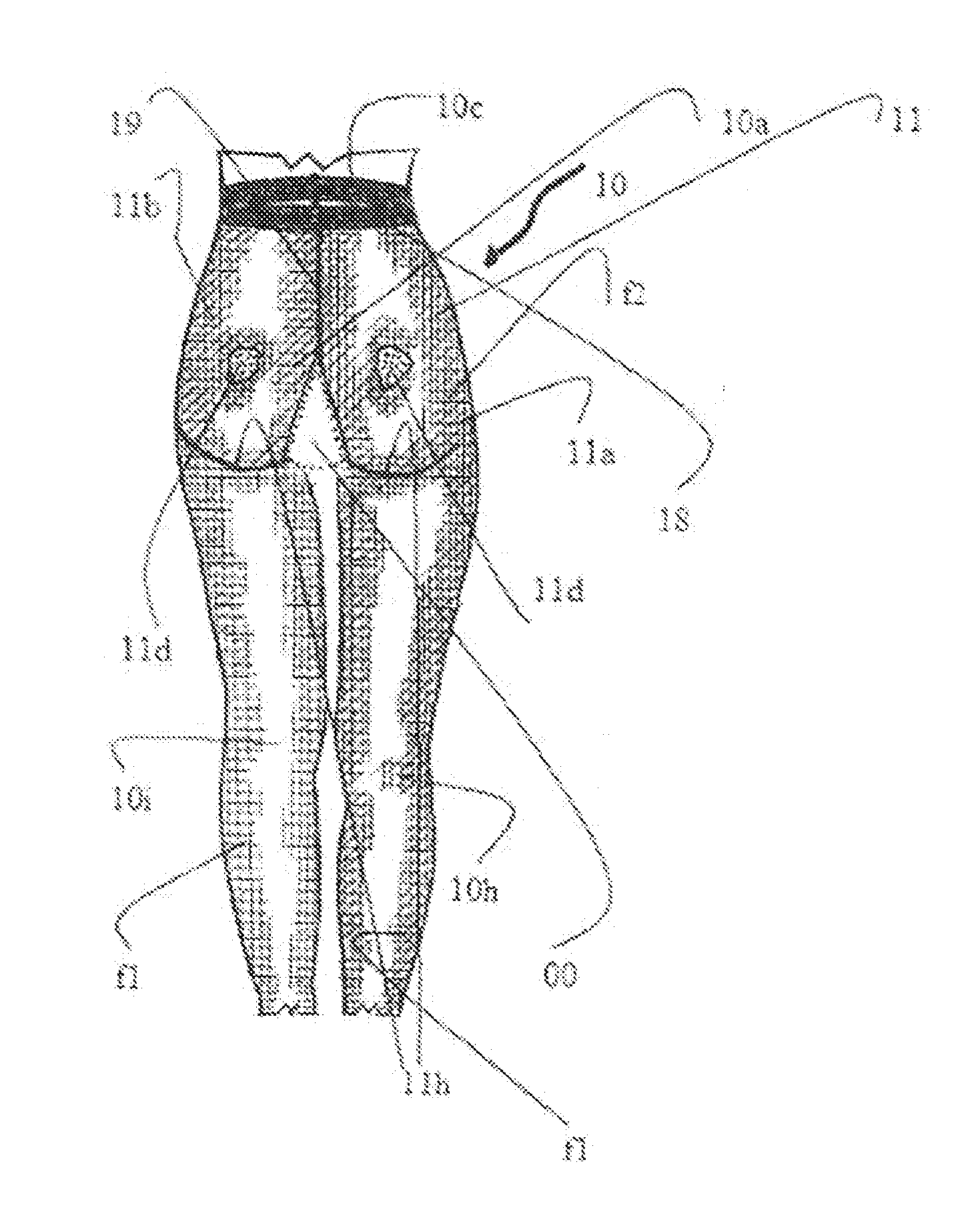

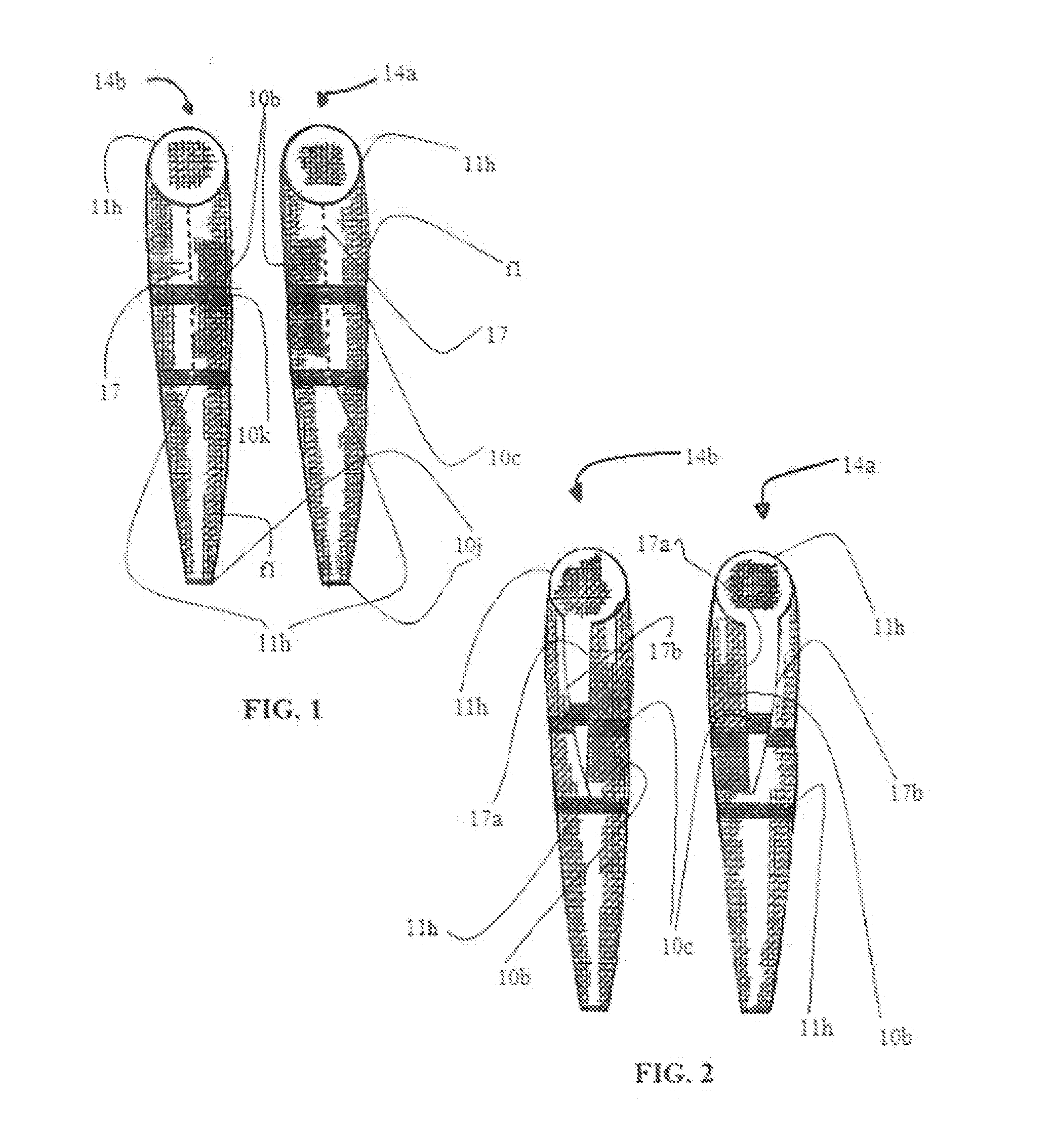

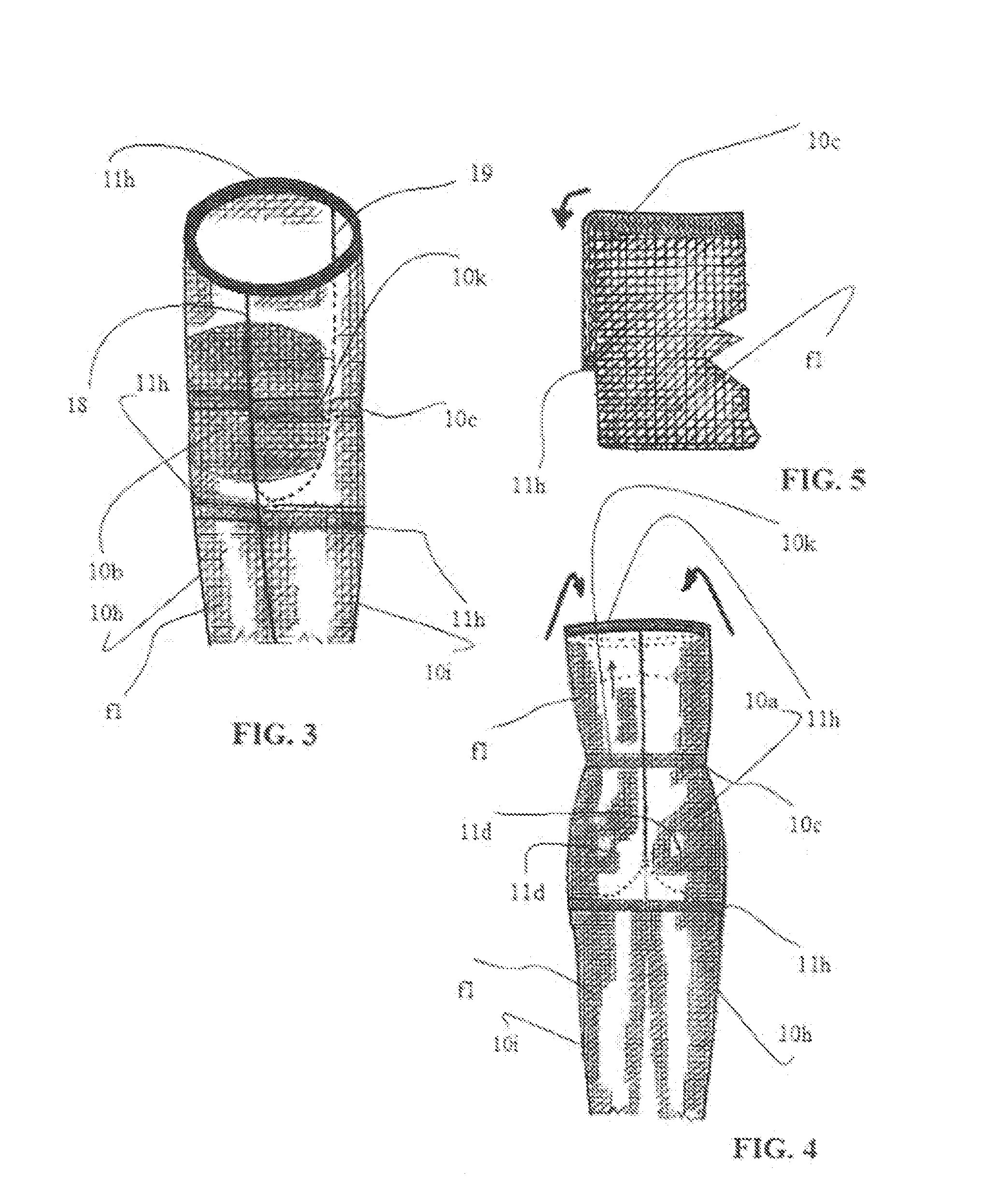

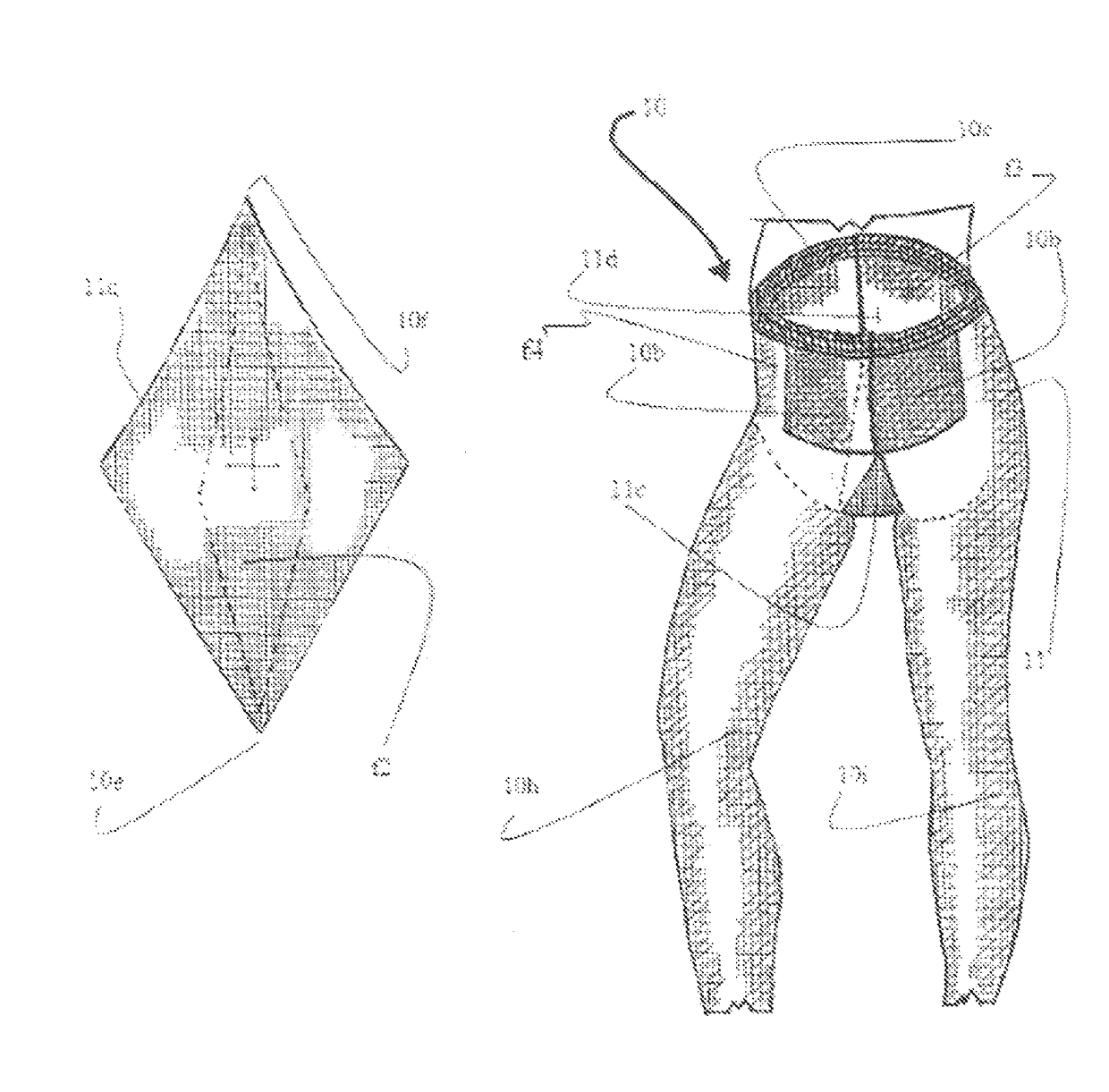

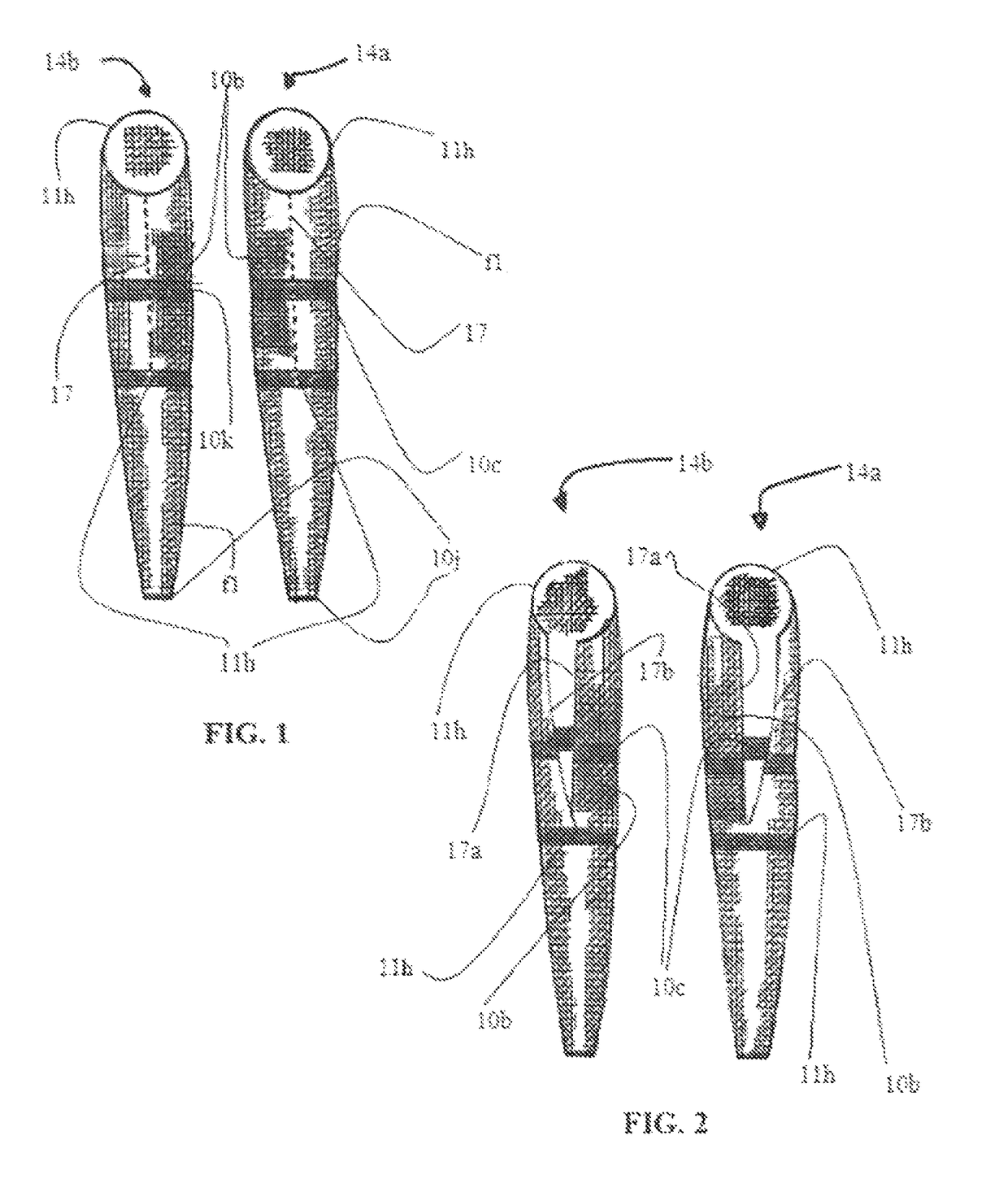

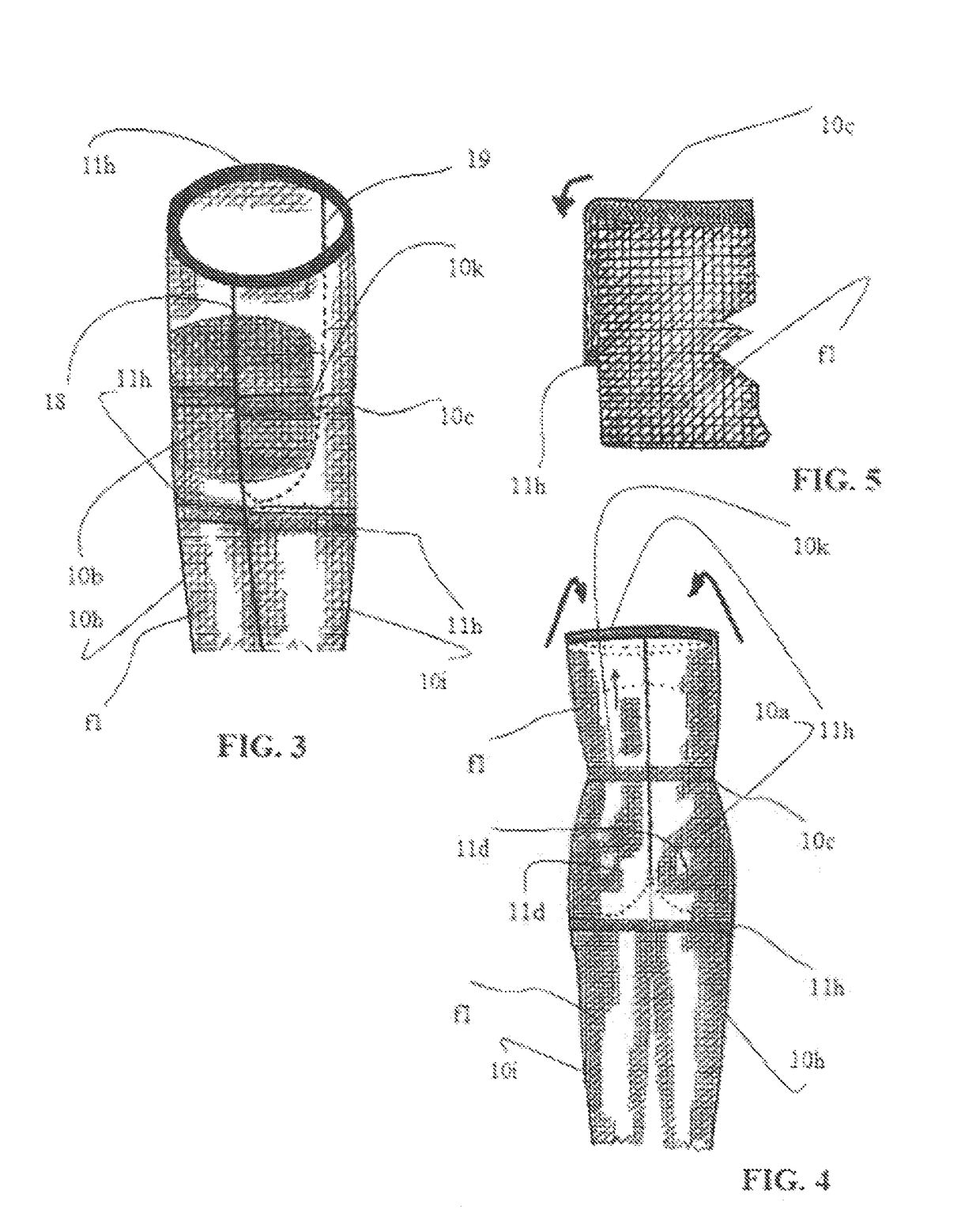

This invention discloses contoured, buttocks enhancing hosiery type undergarments and foundation garments having permanent inner structures of a buttocks enhancing contoured and tapered form system comprising of an open-cell foam pad or shaped silicone gel casing in its rear panel portion fabricated and housed within two-ply fabric portions of highly stretchable yarn, with a further tummy slimming and smoothing function, which eliminates the need for additional or separate buttocks expanding or shaping devices, or girdle type supplemental undergarments. The buttocks enhancing contoured and tapered system is sandwiched and laminated within the two-ply fabric yarn of which the panty portion of the foundation garment is fabricated. The tapered and feathered edges of the contoured buttocks enhancing system allows for a seamless and virtually invisible transition to the single-ply leg portions of the undergarment. Further, the contoured buttocks enhancing and tummy smoothing undergarment allows for great flexibility and comfort regardless of the positioning or movements of the wearer, due in great part to the uniquely designed panty portion, which has coupled with its shape enhancing function a Marque diamond shape two-way highly stretchable and oversized gusset system to allow for ultimate flexibility of movement. The novelty to the invention is the wearer's opportunity to aesthetically improve the lower profile form for a more sexy, natural and sophisticated buttocks appearance while maintaining complete freedom of movement regardless of assumed positions.

Owner:JAMES WINFIELD GILBERT

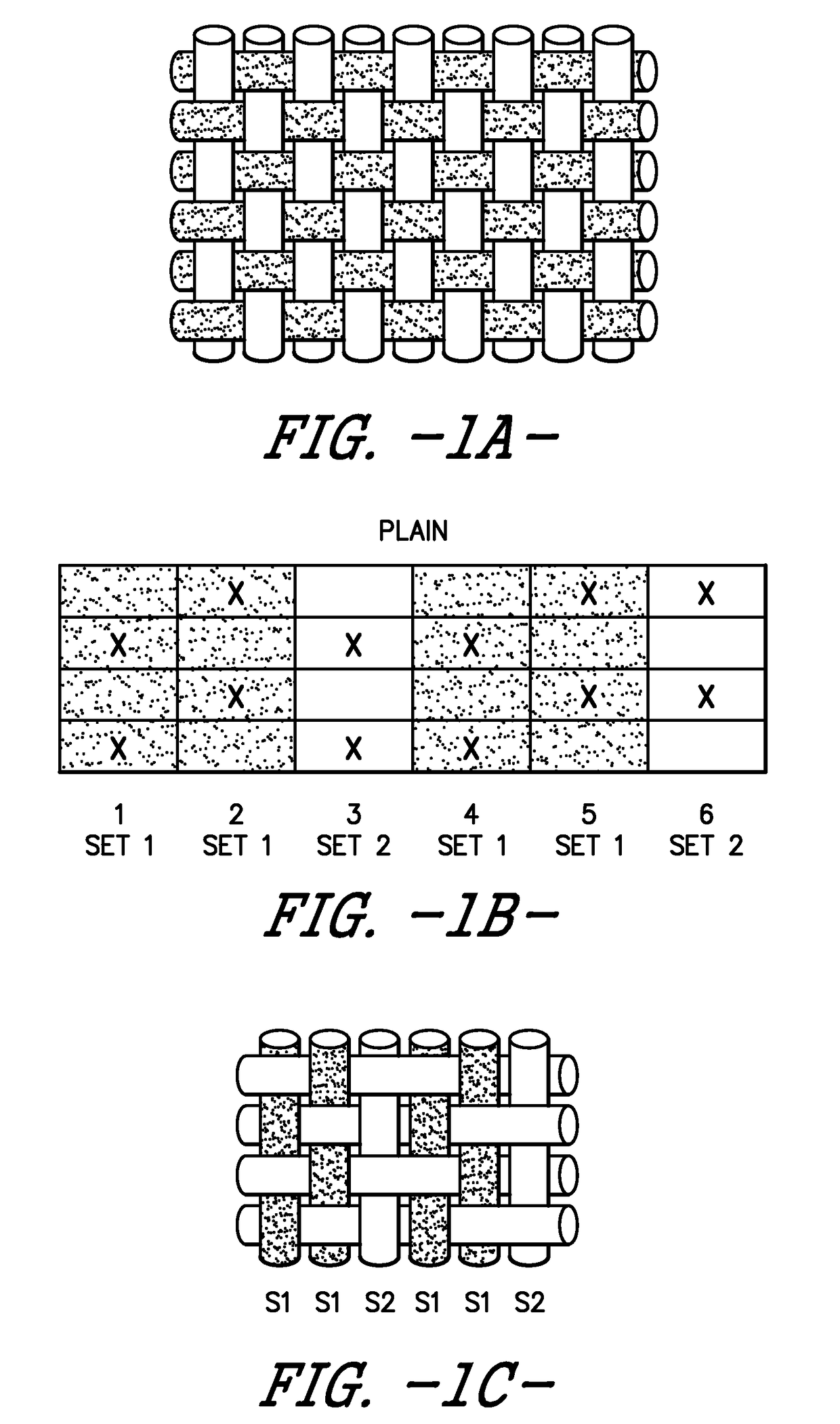

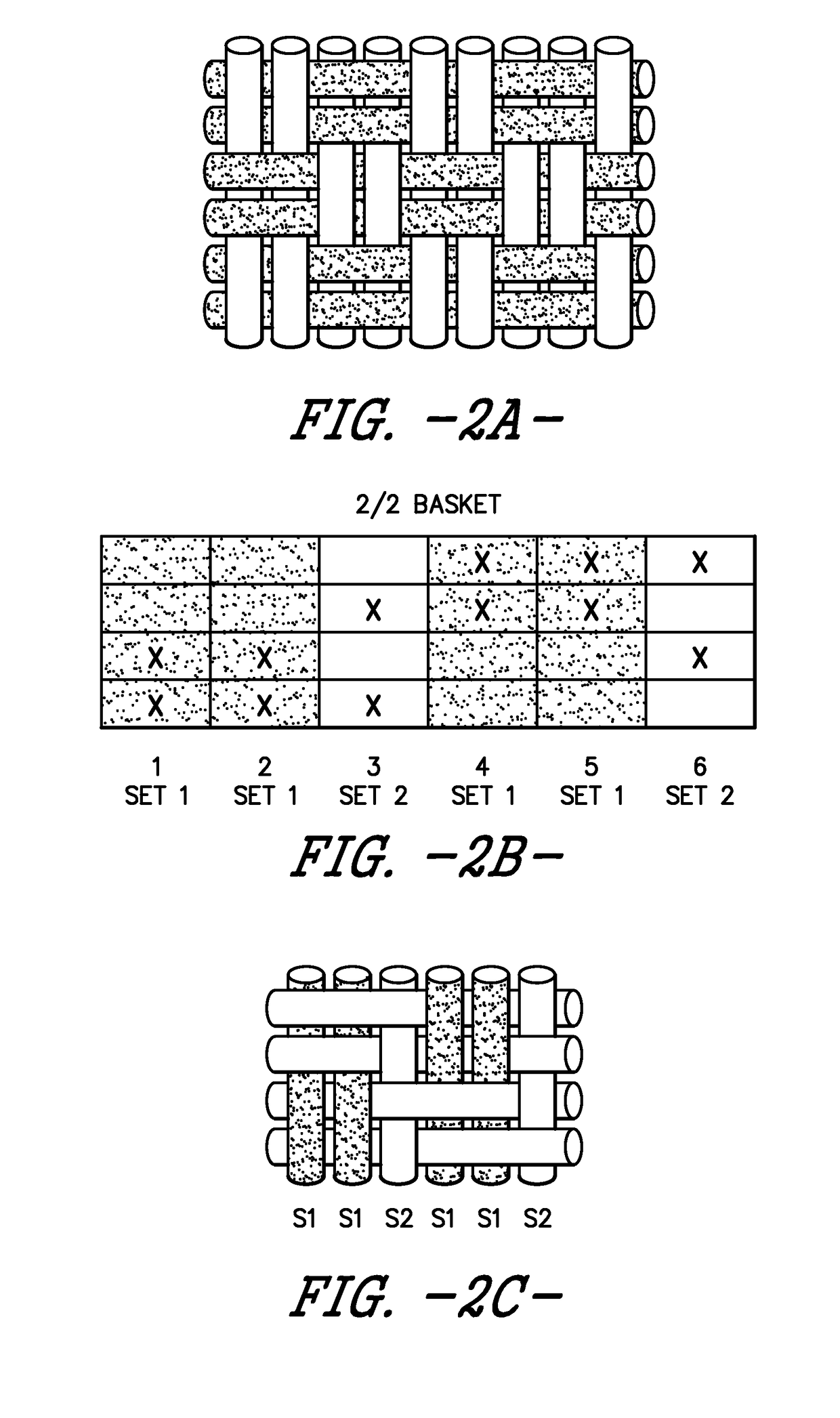

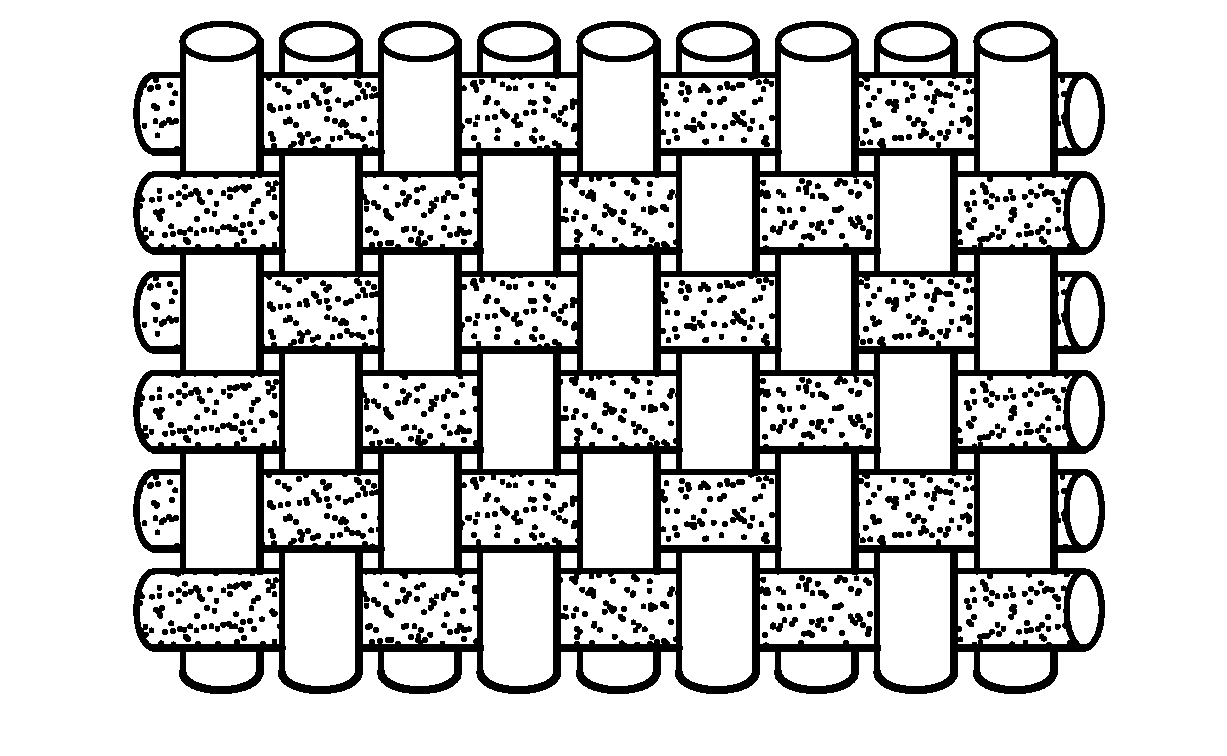

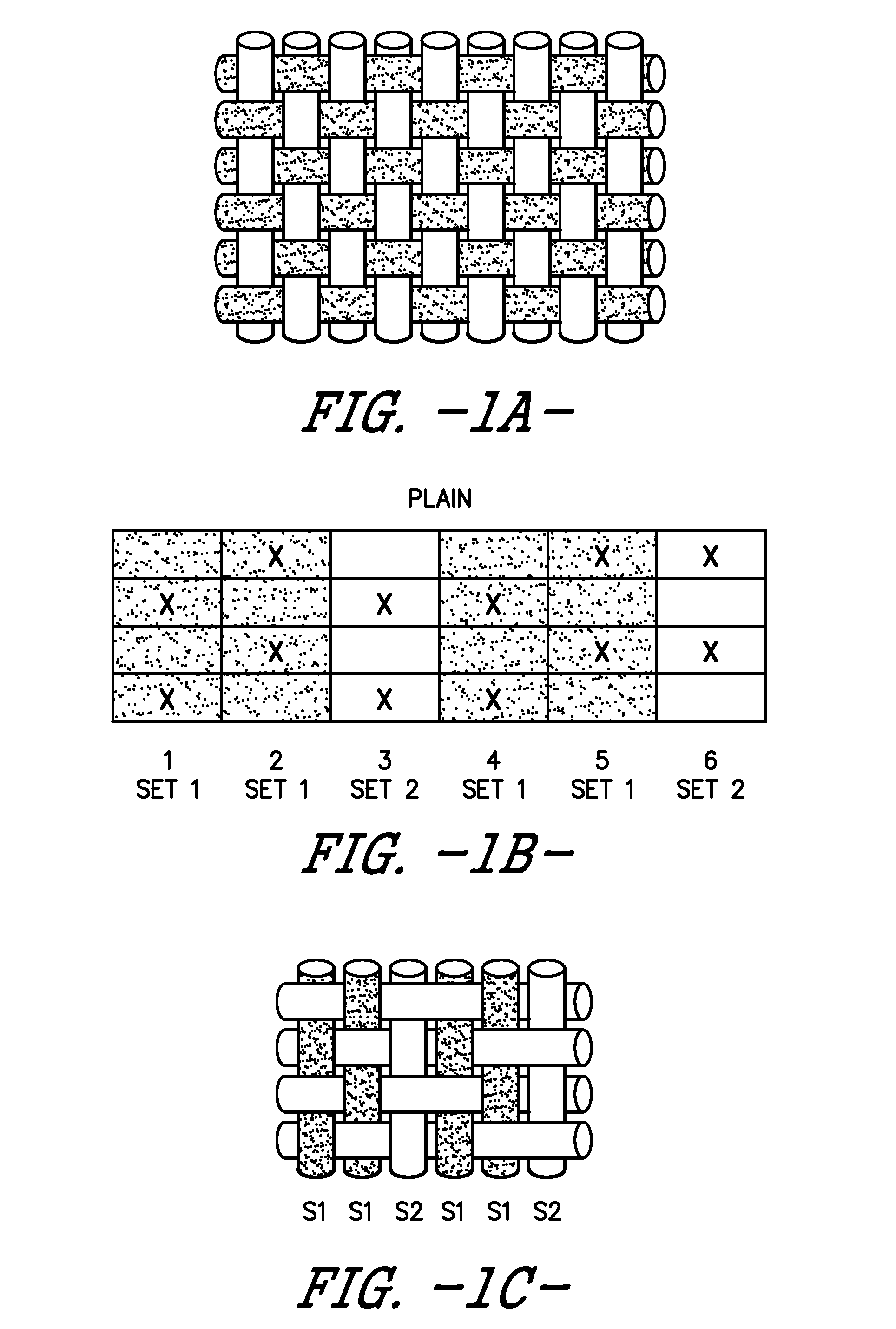

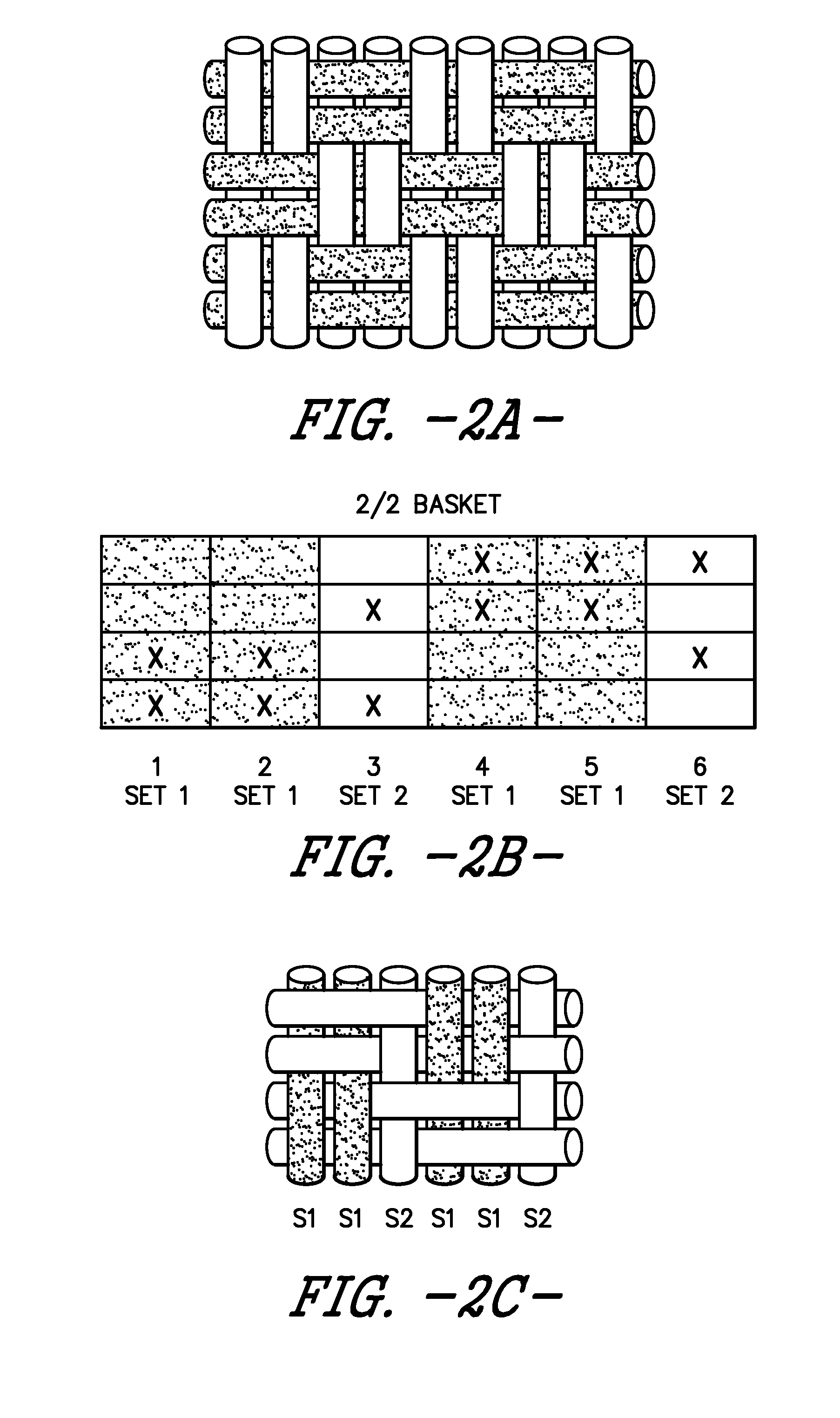

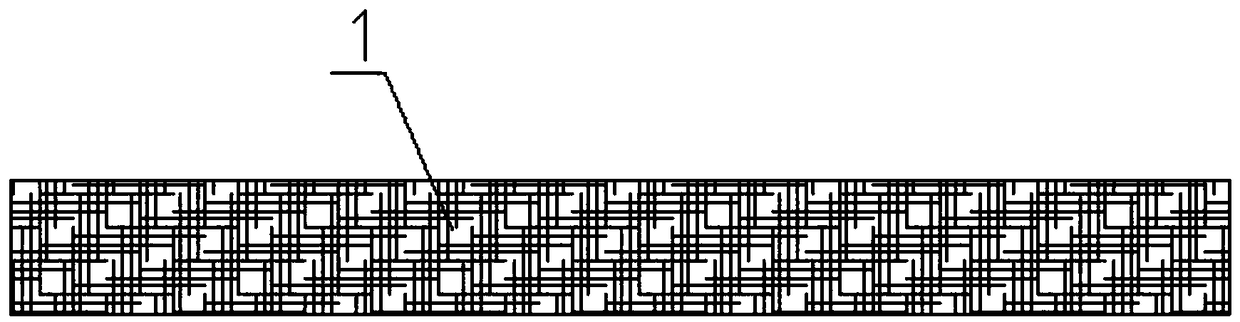

Interlocking weave for high performance fabrics

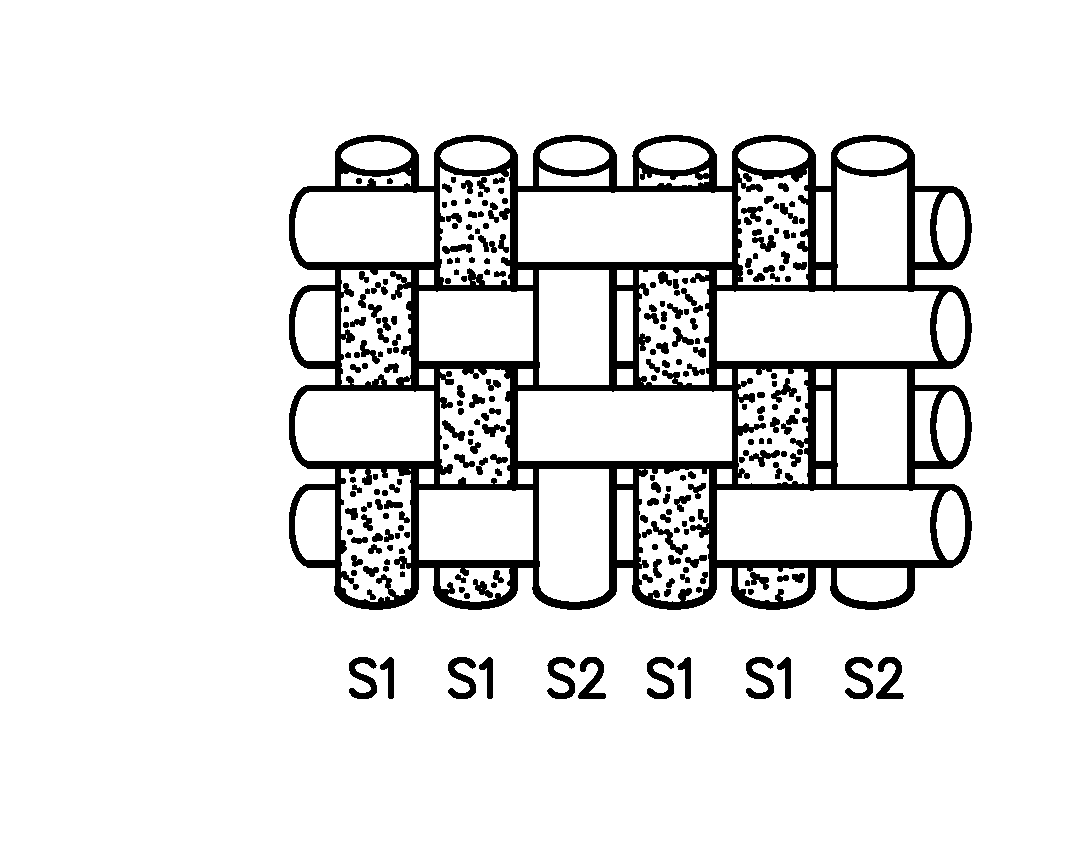

A weave pattern and method for weaving that provides stability to high performance fabrics, such as fabrics used for life protection and composite use, is provided. An additional set of yarn may be added in the warp direction, such that there are two sets of warp yarns per fill yarn alternating throughout the structure of the fabric. This second set of warp yarn locks the fill yarns in place, subsequently interlocking and stabilizing the fabric pattern. This stabilization increases tensile strength, tightness, stiffness, and also improves the handling and cutting of the fabric by resulting in decreased fraying and fiber loss during product construction. Also, the fabric maintains proper shape and form due to the 90 degree interlacing of warp and fill yarns. In this way, the fabric may have the enhanced performance characteristics of a looser weave in combination with the enhanced handleability of a tighter weave.

Owner:JPS COMPOSITE MATERIALS

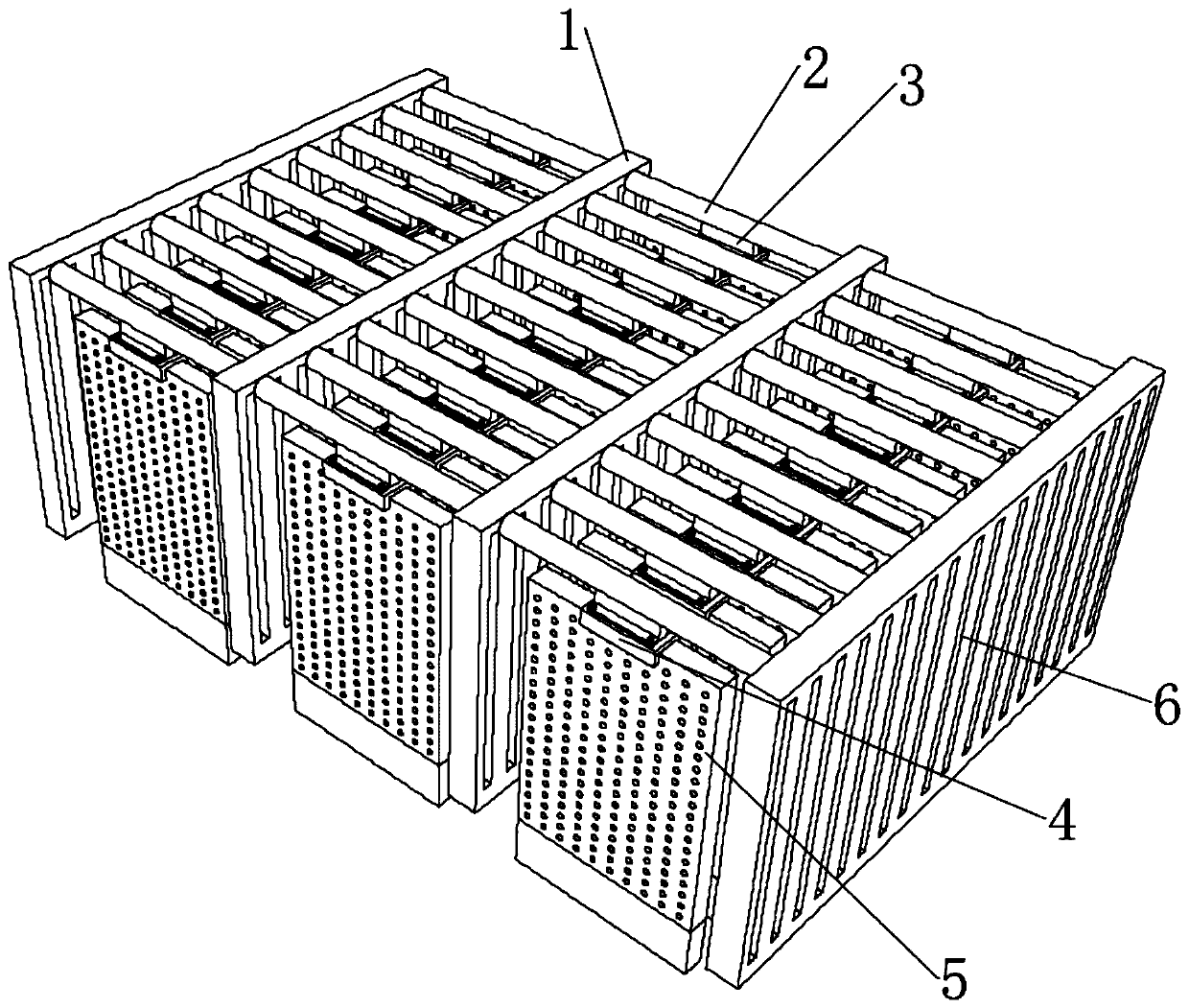

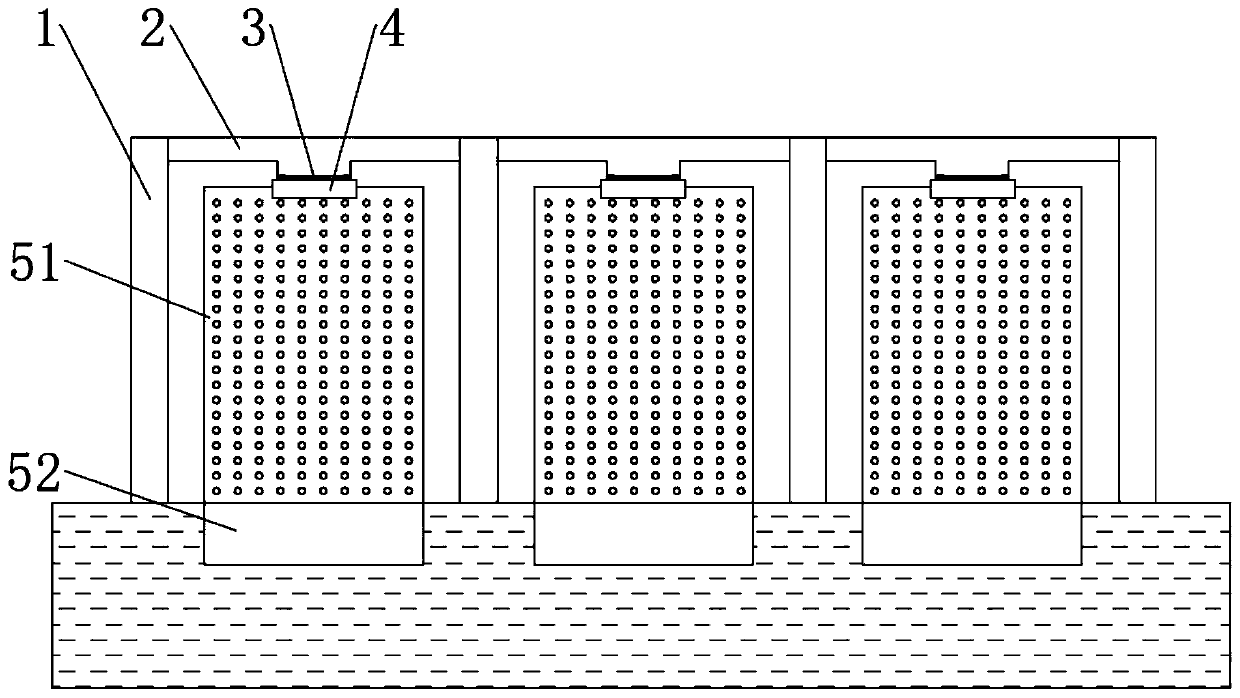

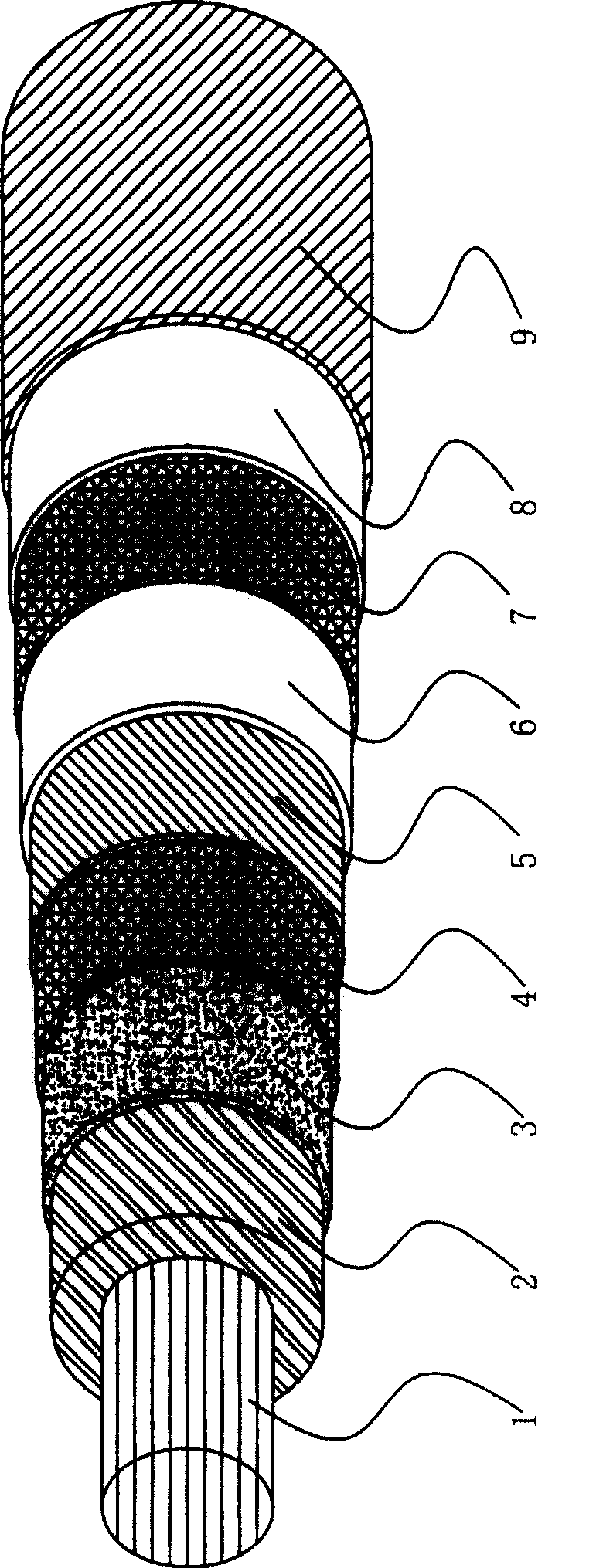

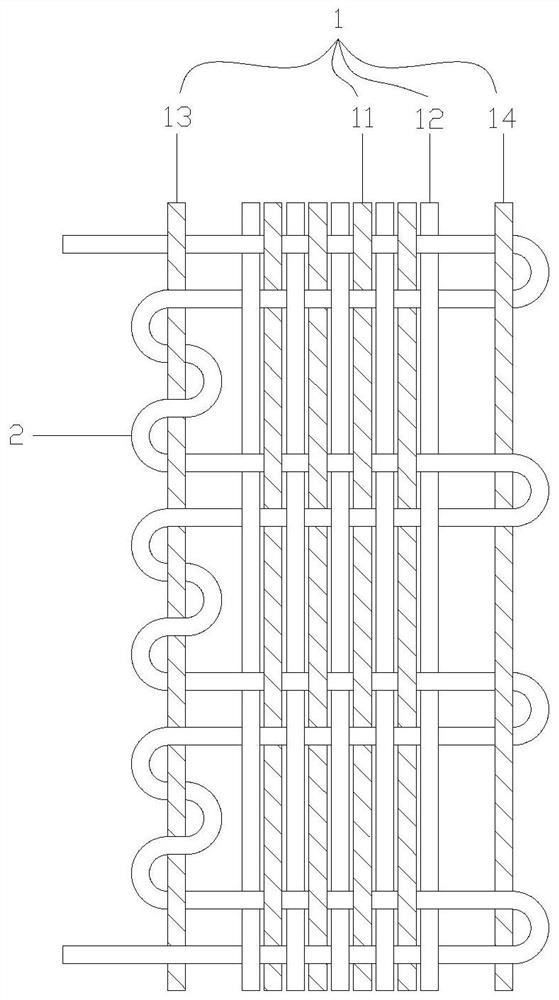

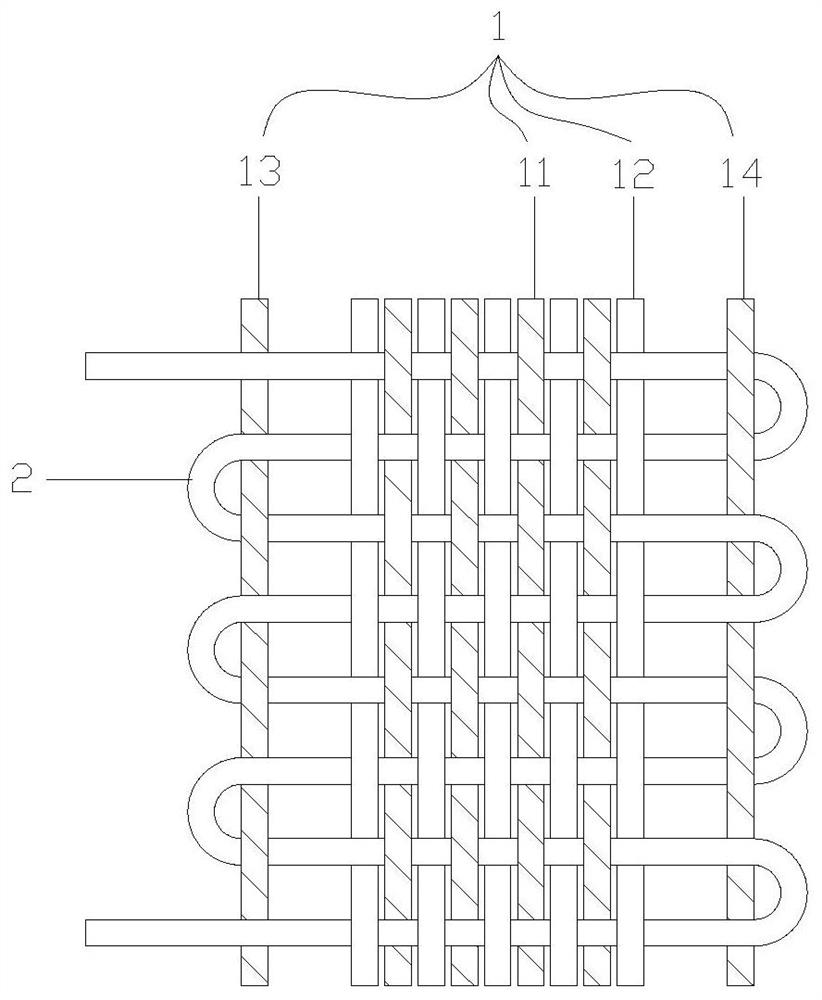

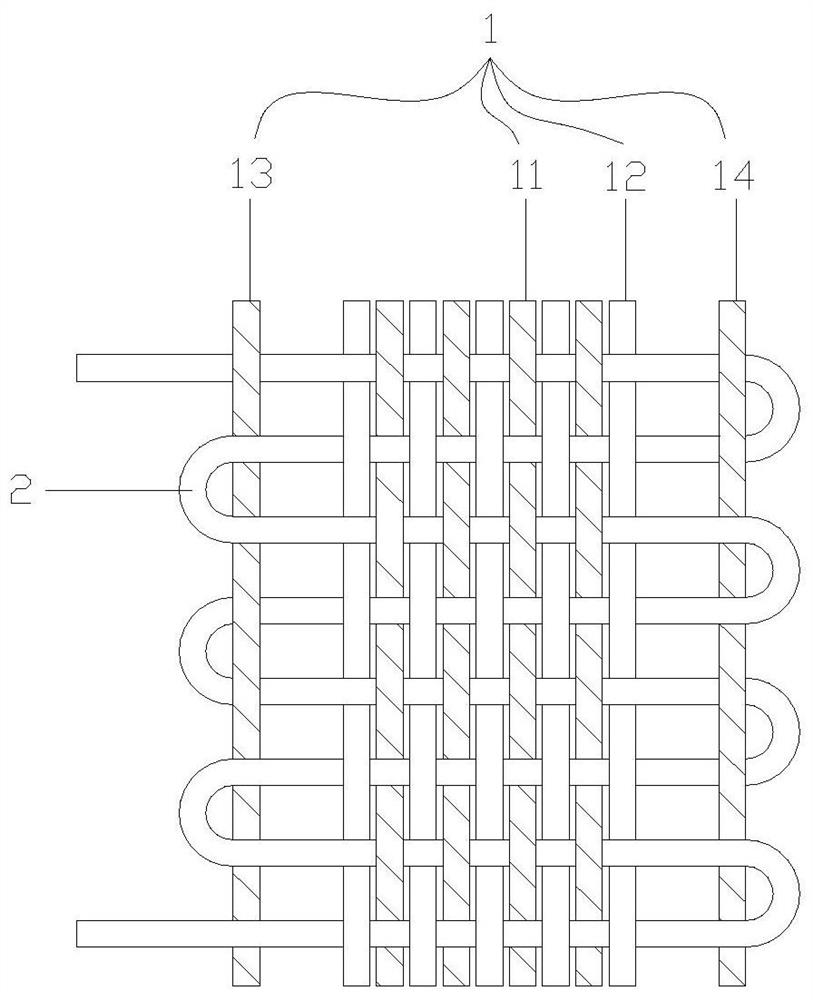

Method and device for accelerating salt-making brine evaporating by using vertical plate water absorption photo-thermal material array

ActiveCN110921683AIncrease evaporation areaReduce lossesEnergy inputAlkali metal chloridesAtmospheric sciencesHeat energy

The invention discloses a method and a device for accelerating salt-making brine evaporating by using a vertical plate water absorption photo-thermal material array. The invention belongs to the technical field of salt production, seawater can be absorbed by utilizing the water absorption photo-thermal material on the basis of capillary action; under the action of light absorption heating balls embedded in the surface, efficient light absorption and utilization of solar energy are realized, conversed heat energy is transferred through a built-in heat conduction framework net to evaporate seawater; only the lower part of the water absorption photo-thermal material is inserted into a water body, the contact area with water surface is small, the loss of photo-thermal energy to the water bodyis greatly reduced, energy utilization rate is enhanced, meanwhile, the water absorption photo-thermal material is vertically placed on the water surface;, the evaporation area of seawater can be directly doubled, it is beneficial for utilization of wind energy, the evaporation area in contact with wind is enlarged, and the evaporation rate is increased; the flapping effect of water waves can be fully utilized to keep the surface of the water absorption photo-thermal material to be wet, the problem of salt precipitation on material surfaces is effectively solved, rapid evaporation of seawateris realized, the salt-making brine evaporating period is greatly shortened, and the salt-making brine evaporating amount is increased.

Owner:江苏金羿射日新材料科技有限公司

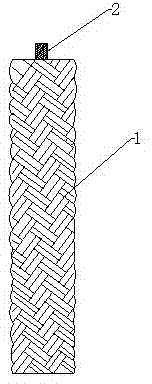

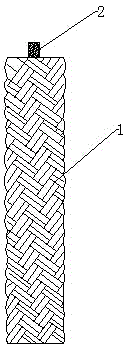

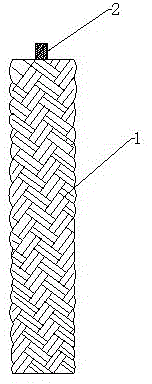

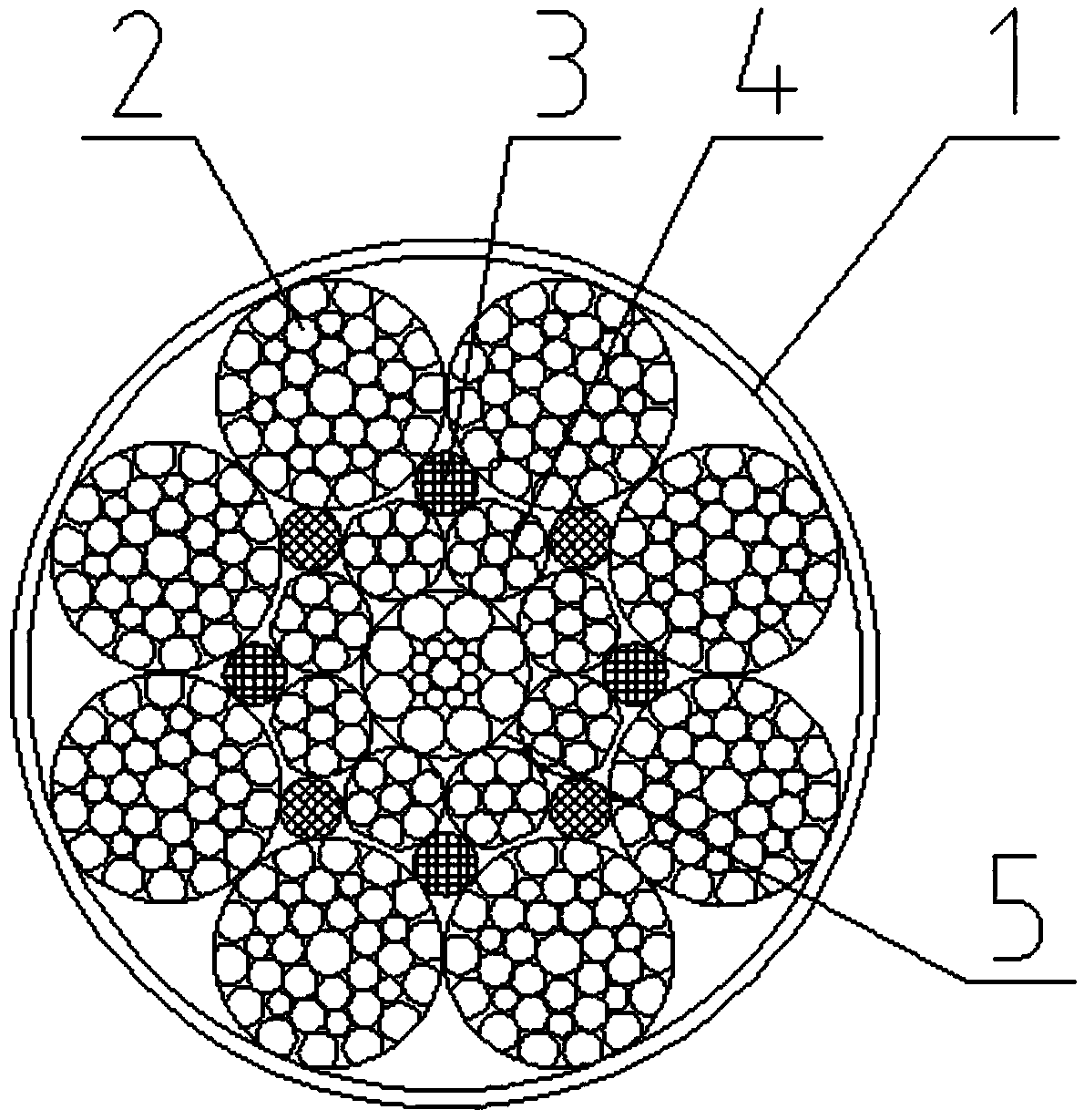

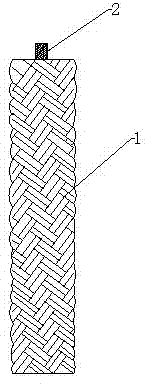

Polyether sulfone fiber compound rope and preparation method thereof

The invention discloses a polyether sulfone fiber compound rope and a preparation method thereof. The polyether sulfone fiber compound rope comprises a rope cover and a rope core, wherein the rope cover is formed by knitting part of polyether sulfone fiber strands in an S twisting direction and another part in a Z twisting direction; the rope cover is an outer sleeve body knitted from a plurality of polyether sulfone fiber strands which are formed by twisting a plurality of polyether sulfone fiber filaments subjected to surface treatment; the rope core is arranged in the rope cover and structured as an integrated body of the polyether sulfone fiber filaments. The polyether sulfone fiber compound rope is compact in knitting, reasonable in process, outstanding in heat resistance, physical and mechanical performances and insulation performance, and suitable for being applied to the site with high humidity and high temperature.

Owner:TAIAN ROPE NET PLASTIC

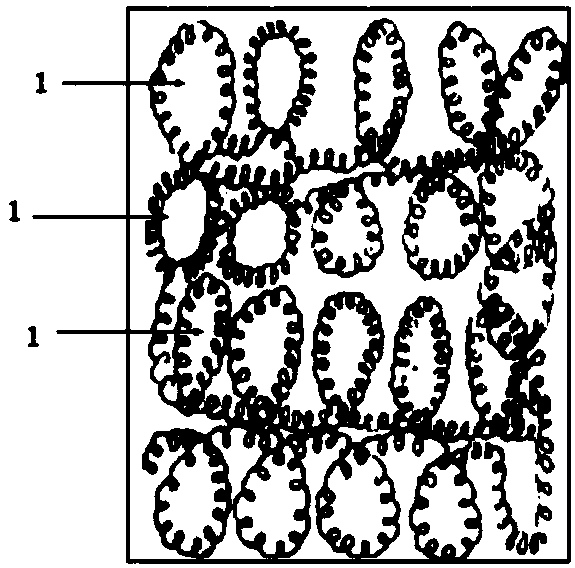

Metal rubber fabricated part and preparation thereof, and preparation method of metal rubber ring

PendingCN110345185AMeet preparationIncrease dampingElastic dampersShock absorbersPolymer scienceMetal rubber

The invention discloses a metal rubber fabricated part and a method thereof, and a preparation method of a metal rubber ring. The metal rubber fabricated part comprises a core body and a coating body,wherein the core body comprises a plurality of O-type weaving layers; each O-type weaving layer comprises a plurality of O-type structures formed by winding metal wires; the adjacent O-type structures of the adjacent layers incompletely coincide; the coating body coats the outer part of the core body, and comprises a plurality of first diagonal type weaving layers; each first diagonal type weaving layer is formed by winding metal wires in the same inclining direction; and the metal wires between the adjacent first diagonal type weaving layers form a first X-type structure. The metal rubber fabricated part is not filled with a die or a weaving process ruler, so that the preparation of the large metal rubber fabricated part is met. The invention also provides the preparation of the metal rubber ring. A metal rubber blank part is formed by winding the meal rubber fabricated part on a core shaft and weaving the metal rubber fabricated part, and is subjected to compression moulding to formthe metal rubber ring. Through the adoption of the method, layering and cracking of metal rubber can be avoided.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Contoured buttocks enhancing and tummy slimming hosiery and foundation garment

The invention discloses a contoured, buttocks enhancing hosiery foundation garment having permanent inner structures of a buttocks enhancing system comprising an open-cell foam pad or silicone gel casing in its rear panel portion fabricated and housed in two-ply fabric portions of stretchable yarn, with a tummy slimming function which eliminates the need for additional shaping devices or girdle type foundation garment. The buttocks enhancing contoured and tapered system is laminated in the two-ply fabric of which the panty portion of the garment is fabricated. The tapered edges of the buttocks enhancing system allows for a seamless and transition to the single-ply leg portions. The contoured buttocks enhancing and tummy smoothing foundation garment allows for great flexibility and comfort regardless of the movements of the wearer due to the structure of the panty portion with the marquise diamond shaped two-way stretchable and oversized gusset system.

Owner:JAMES WINFIELD GILBERT

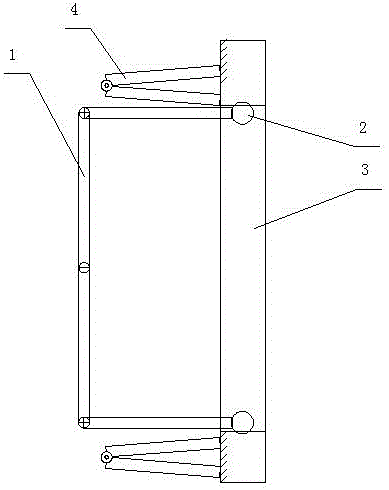

Foldable clothes-airing rod

ActiveCN106149322AEasy to dryQuick storageAnti-corrosive paintsOther drying apparatusEngineeringRainy weather

The invention relates to an intelligent clothes-airing device and belongs to the field of smart home. The invention specifically relates to a foldable clothes-airing rod which comprises a foldable shaft and a clothes-airing rod body, wherein the clothes-airing rod body is fixed on the foldable shaft and the clothes-airing rod body can be rotated around the foldable shaft so as to put the clothes on the clothes-airing rod body in the indoor or outdoor space. The invention discloses the foldable clothes-airing rod. The transfer of the clothes from the indoor space to the outdoor space can be quickly realized; the clothes are effectively protected; under gale or rainy weather, the clothes settlement and storage can be quickly realized; in the storage process, the clothes are prevented from falling off; the intelligent and automatic clothes airing can be realized; the household comfort is increased; the intelligent degree of smart home is increased; the structure is simple, the use is convenient and the intelligent clothes-airing device is easy to popularize; the airing quality of the clothes can be effectively ensured; the clothes can be conveniently placed in the indoor or outdoor space; the clothes can be conveniently hung.

Owner:浙江国正安全技术有限公司

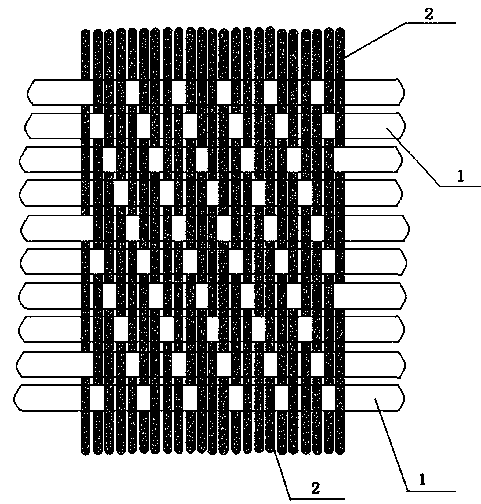

Woven fabric with electromagnetic wave shielding function

The invention discloses woven fabric with the electromagnetic wave shielding function. The woven fabric is formed by weaving textile yarn and semiconductor fiber yarn, the textile yarn serves as abbs, the semiconductor fiber yarn serves as warps, the piece number of the textile yarn is 2-4 times that of the semiconductor fiber yarn, and the ratio of warp operator points to abb operator points is 1-4:1. According to the woven fabric with the electromagnetic wave shielding function, due to the stranding design of the semiconductor fiber yarn and the structural design of warps and the abbs, the fabric with semiconductor fibers is more compact in weave and thorough in shielding effect on various electromagnetic waves. Meanwhile, due to the stranding design, the fabric is more comfortable, and compared with a piece of existing radiation-proof clothes, the fabric is more convenient and easier to clean.

Owner:无锡荣能半导体材料有限公司

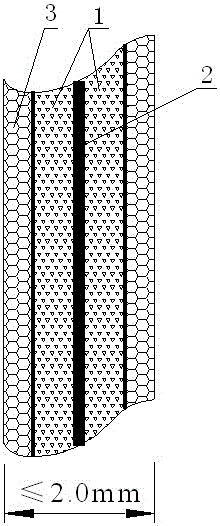

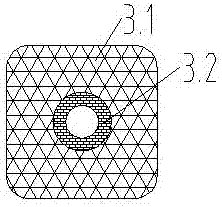

Inorganic fiber composite fire-proof fabric base cloth material and application thereof

Disclosed is an inorganic fiber composite fire-proof fabric base cloth material. The inorganic fiber composite fire-proof fabric base cloth material is produced according to the steps of subjecting inorganic glass fibers 1 and stainless steel wires 2 to stranded weaving, conducting warp-weft weaving to reach compact density and coating the surface with micro-particle aluminothermic reflective polymer coating 3. Further, every inorganic glass fiber bundle can be composed of multi-stranded single-glass fiber yarn materials into which a stainless steel wire is embedded. The inorganic fiber composite fire-proof fabric base cloth material has the advantages of high warp / weft tensile strength, excellent flexible structure reducibility, extremely low smoke leakage amount, long fire-resistant time, suitability for firing environments with the temperature above 1,000 DEG C, light weight, thinness, fire resistance, high smoke prevention capability, high tensile strength, skillful design and capability of being implemented as a fabric base cloth material for safety emergency products and is applicable to finished products of high-temperature-resistant, fire-resistant, smoke-preventive and fire-resistant equipment and facilities employed in the fields such as aerospace, ships and warships, subway carriages, mineral products and industrial and civil buildings.

Owner:上海斯诺柯乔安全防范技术有限公司

Interlocking weave for high performance fabrics

A weave pattern and method for weaving that provides stability to high performance fabrics, such as fabrics used for life protection and composite use, is provided. An additional set of yarn may be added in the warp direction, such that there are two sets of warp yarns per fill yarn alternating throughout the structure of the fabric. This second set of warp yarn locks the fill yarns in place, subsequently interlocking and stabilizing the fabric pattern. This stabilization increases tensile strength, tightness, stiffness, and also improves the handling and cutting of the fabric by resulting in decreased fraying and fiber loss during product construction. Also, the fabric maintains proper shape and form due to the 90 degree interlacing of warp and fill yarns. In this way, the fabric may have the enhanced performance characteristics of a looser weave in combination with the enhanced handleability of a tighter weave.

Owner:JPS COMPOSITE MATERIALS

Cashmere cotton fabric

InactiveCN108656658ATightly wovenPlump appearanceSucessive textile treatmentsTwo or more solvent application treatmentFiberMoisture absorption

The invention provides a cashmere cotton fabric. The cashmere cotton fabric comprises an outer layer and a lining layer; and the outer layer is composed of cashmere fibers and PTT fibers, and the lining layer is composed of modal fibers and pure cotton fibers. Compared with the prior art, The cashmere cotton fabric provided by the invention has the following beneficial effects: the cashmere cottonfabric has more compact tissue, and the product has fuller appearance and slide and smooth hand feeling, is rich in elasticity, and has good wear resistance and excellent moisture absorption performance.

Owner:珠海利得威时装有限公司

Industrial rope and preparation method thereof

The invention discloses an industrial rope and a preparation method thereof and relates to the field of weaved ropes. The industrial rope comprises a rope skin and a rope core, wherein the rope skin sleeves the rope core and combines weaving to form the rope; the rope skin is an outer sleeve body formed by twisting and pre-weaving nylon 6 fiber filaments; the nylon 6 plied yarns for pre-weaving the rope skin is formed by twisting five nylon 6 fiber filaments; the rope core is formed by three-ply twisted yarns of nylon 66 fiber filaments; four nylon 66 fiber filaments for twisting the rope core are arranged. According to the invention, the rope skin is manufactured from the nylon 6 fiber filaments, the rope core is manufactured from the nylon 66 fiber filaments, the rope skin and the rope core are combined and weaved to integrally form the industrial rope; the characteristics of the nylon 6 fiber filaments and the nylon 66 fiber filaments are utilized, so that the industrial rope has the characteristics of light weight, low malleability, high strength and excellent safety performance, is suitable for large-scale production and application, and meets the basic requirements of industrial ropes.

Owner:TAIAN ROPE NET PLASTIC

Nano high-temperature resistance flame-retardation fiber rope and production method

The invention discloses a nano high-temperature resistance flame-retardation fiber rope and a production method, the nano high-temperature resistance flame-retardation fiber rope comprises rope sheath and a rope core arranged in the rope sheath, the rope sheath is arranged as a jacket body braided by half S-twist-direction nano high-temperature resistance flame-retardation fiber strand and half Z-twist-direction nano high-temperature resistance flame-retardation fiber strand, and the rope core is arranged as the nano high temperature-resistance flame-retardation fiber filament complex. The nano high-temperature resistance flame-retardation fiber rope has the advantages of compact braiding, reasonable technology, high temperature resistance of products, good flame retardation performance and high safety.

Owner:TAIAN ROPE NET PLASTIC

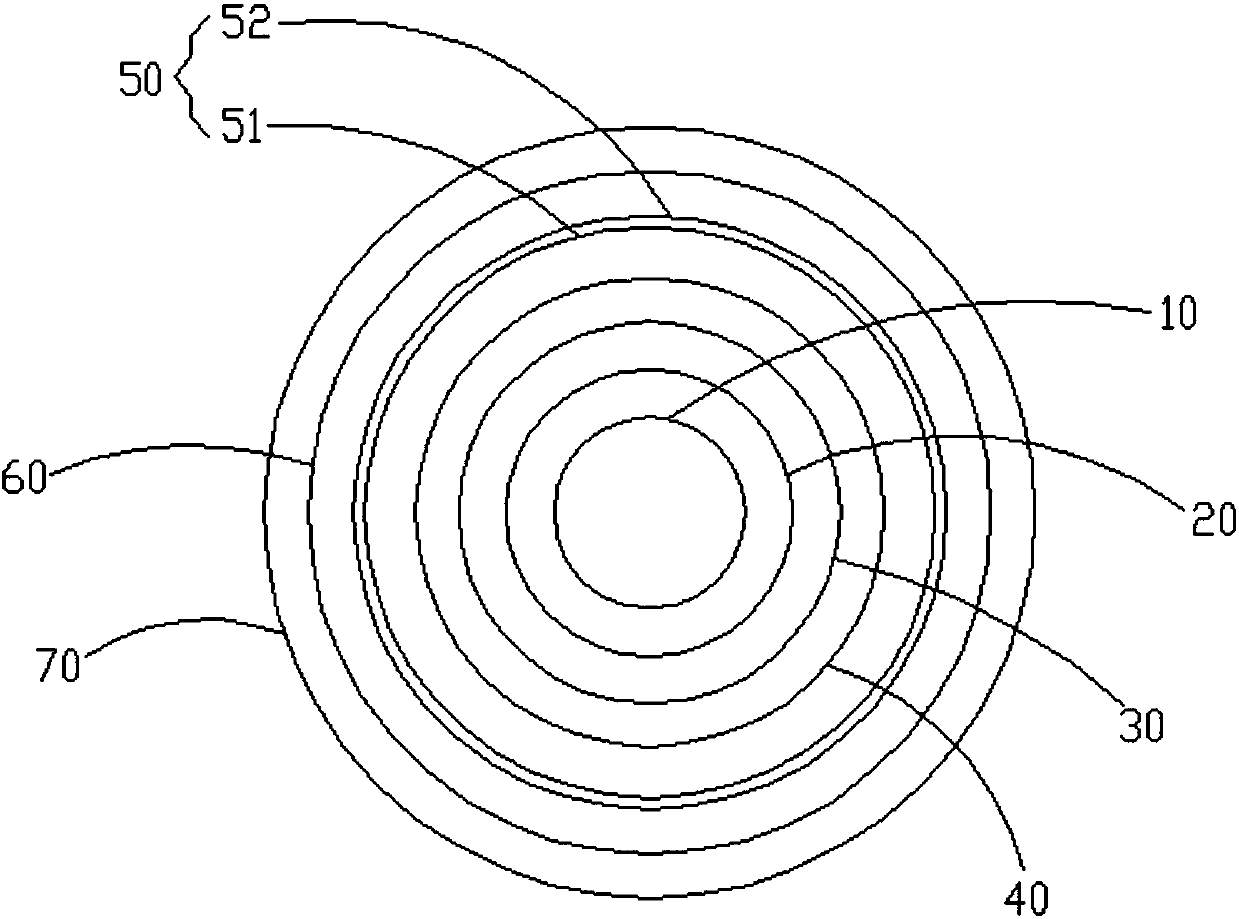

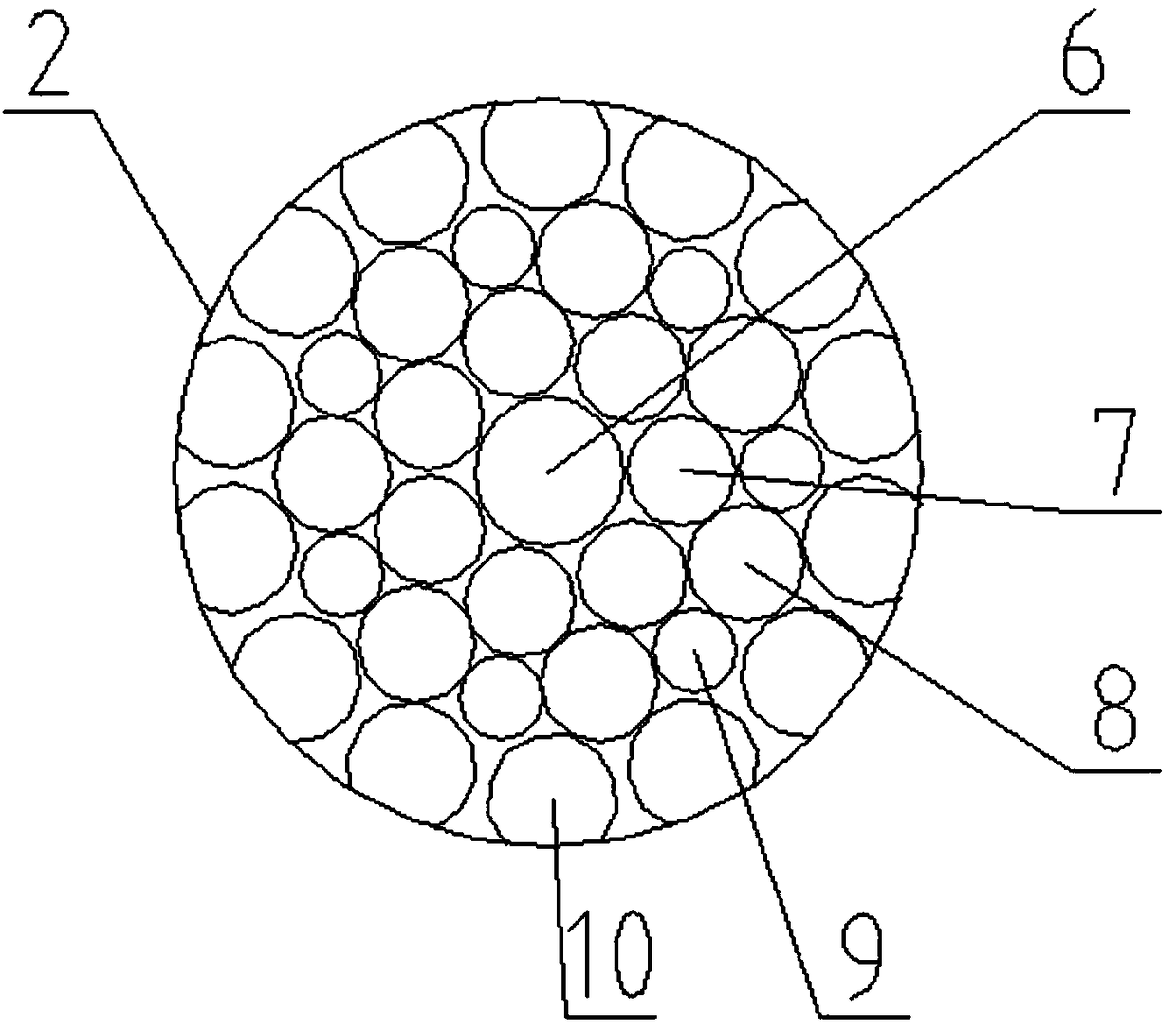

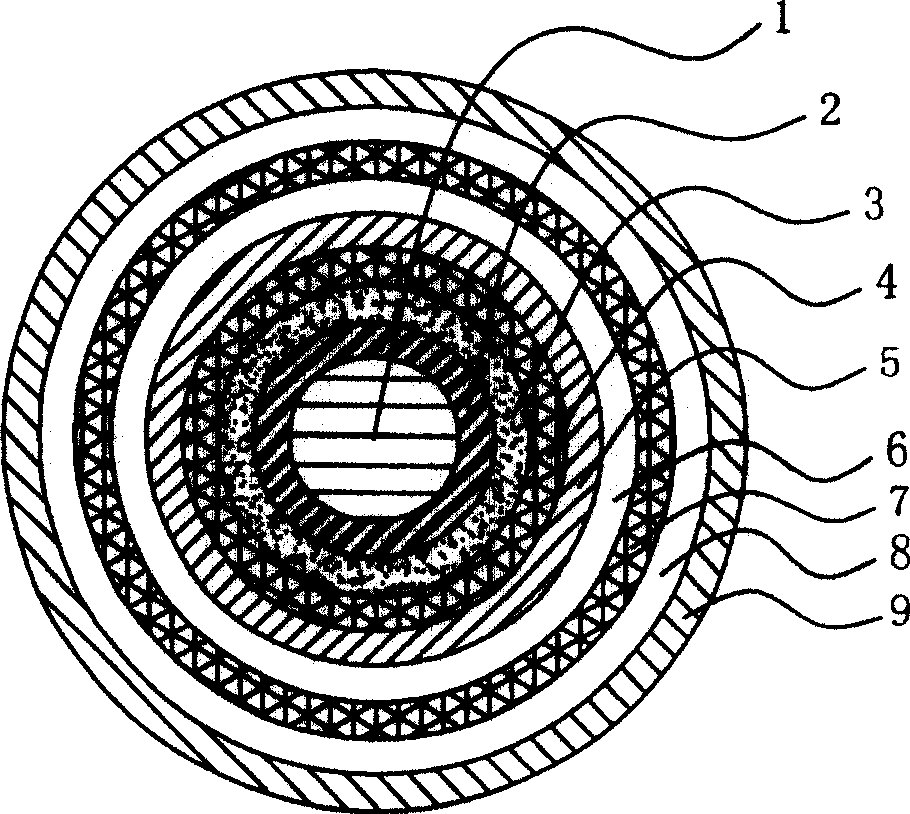

Cable for new energy vehicle

InactiveCN107742552AImprove shielding effectAffect the effect of high pressure resistancePower cables with screens/conductive layersInsulated cablesElectrical conductorAcute angle

The invention discloses a cable for a new energy vehicle, and belongs to the field of new energy vehicles. The cable comprises a conductor, an internal belting layer, an insulating layer, a tensile layer, a shielding layer, an external belting layer and a sheath which are arranged in sequence from inside to outside in the radial direction. By means of the internal belting layer and the external belting layer, the conductor and a woven part are more rounding and compact, and the phenomenon that the conductor loosens or becomes oval, so that the performance is lowered, and the high pressure resistant effect of the cable is affected can be effectively avoided; by means of the tensile layer, the tensile strength of a wire can be increased, and meanwhile the effect that acute angle bending is conducted without cracking is achieved; by means of the shielding layer, the very high shielding effect is achieved, and low-frequency interference can be more effectively resisted.

Owner:郑州栾信科技有限公司

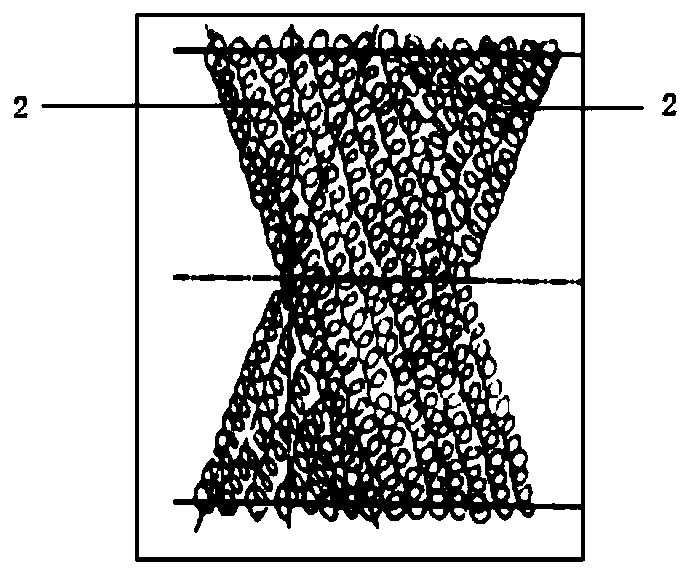

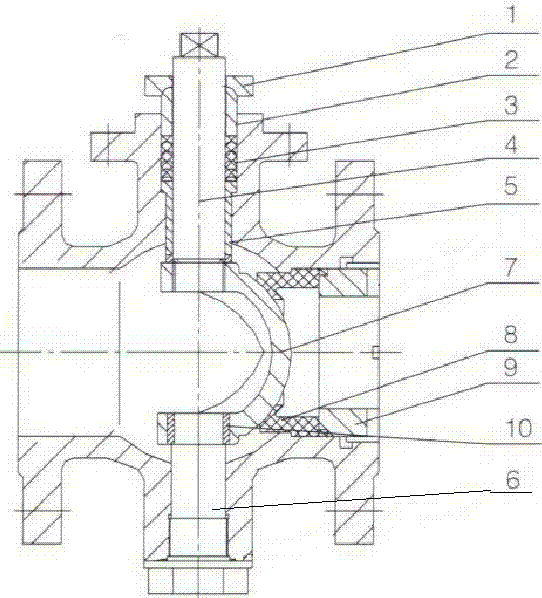

Novel adjusting ball valve

InactiveCN107514502AFlexible installationReduce weightSpindle sealingsPlug valvesValve seatBall valve

The invention discloses a new type of regulating ball valve, which comprises a packing pressure plate, a packing gland, a packing, an upper valve stem, a valve stem bearing, a lower valve stem, a valve core and a valve seat. The valve core and the valve seat are installed in the valve body. The valve seat is fixedly installed in the valve body through the pressure ring, the lower end of the upper valve stem is fixedly installed on the top of the valve core through the through hole at the top of the valve body, and the upper end of the upper valve stem is fixedly installed on the valve core through the through hole at the bottom of the valve body There is a stem bearing between the upper valve stem and the valve body, and a packing is provided on the top of the valve stem bearing, and the packing is pressed between the upper valve stem and the valve body through the packing gland and the packing pressure plate. In the cavity; the filler is packing, and the filler includes a braided layer and an elastic layer, and the braided layer is arranged outside the elastic layer and wraps the elastic layer. The technical purpose of the present invention is to provide a new type of regulating ball valve with more reliable valve stem seal and more durable valve stem seal.

Owner:CHENGDU DESHANNENG TECH CO LTD

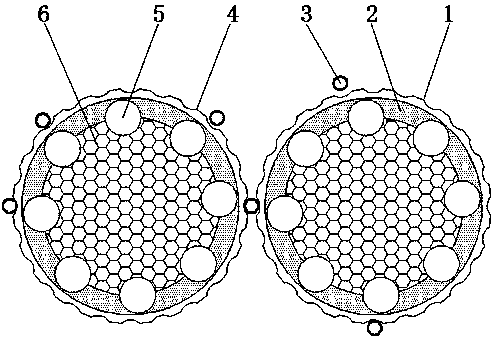

Polymer synthetic fiber rope and processing method thereof

InactiveCN108442153AAvoid damageHigh breaking forceTextile cablesWear resistancePolytetrafluoroethylene

The invention discloses a polymer synthetic fiber rope and a processing method thereof. The polymer synthetic fiber rope comprises a coated fiber layer, an outer layer strand, an auxiliary layer strand and an inner layer main strand, wherein the outer layer strand is arranged in the coated fiber layer, a polyester fiber is arranged in the outer layer strand, a polyamide fiber is arranged at the inner side the polyester fiber, a polyacrylonitrile fiber is arranged within the polyamide fiber, a polyethylene fiber is arranged at the inner side of the polyacrylonitrile fiber, a polytetrafluoroethylene fiber is arranged at the inner side of the polyethylene fiber, the inner side of the outer layer strand is provided with the auxiliary layer strand, the inner side of the auxiliary layer strand is provided with the inner layer main strand, and the inner side of the inner layer main strand is provided with a central strand. The polymer synthetic fiber rope and the processing method thereof have the advantages that the effect of high temperature and corrosion resistance is good, the wear resistance is good, the strength is high, the service life is long, the weaving is compact, rope skin coats the outer surface of the rope to reduce the damage on the internal rope, the fatigue resistance and bearing capacity are good, the breaking tensile force of the fiber rope can be improved, and theuse efficiency is high.

Owner:天津市长金制线有限公司

Basalt fiber gridding cloth reinforced composite material and preparation method thereof

ActiveCN110804297AImprove performanceLongitudinal and transverse strength are the sameFlat articlesNew energyBasalt fiber

The invention discloses a basalt fiber gridding cloth reinforced composite material and a preparation method thereof, and relates to the field of new materials. The material can be used for replacingsteel and aluminum materials to be used for interior trim of automobiles and new energy vehicles, part of vehicle body frameworks and vehicle shells to reduce the dead weight of the vehicles. The basalt fiber gridding cloth reinforced composite material comprises the following components in parts by weight: 500-1500 g / m<2> of basalt fiber gridding cloth, 20-80 parts of PC resin, 80-20 parts of ABSresin, 0-1 part of an antioxidant, 0-2 parts of a lubricant, 0-200 ml of mineral oil and 0-5 parts of a coupling agent.

Owner:NANCHONG XUYANG PLASTIC MFG CO LTD

Medical ion-chamber cable

InactiveCN100466110CTightly wovenThe weave is not loosePlastic/resin/waxes insulatorsInsulated cablesPolyesterElectrical conductor

This invention relates to a kind of medical ion chamber cable, ento-ectad including a inner conductor, a high megohm resistance insulating layer, a plumbago layer, the first shielding layer preventing electromagnetic field interfering, a PVC inner protective layer, a polyester layer, the second shielding layer preventing electromagnetic field interfering, an outer protective layer preventing fire. The feature of the inner conductor is that it is made up of a nickel-copper silvering wire. The advantage of the invention is that the high-density, optimized and multi-layer shielding structure not only prevents electromagnetic field interfering effectively, but improves the effect of the medical ion chamber measuring low-activity radial source in the short range.

Owner:高思义

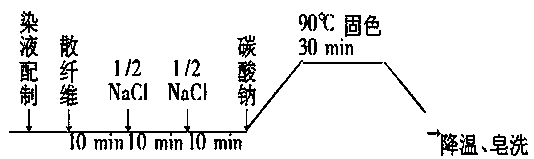

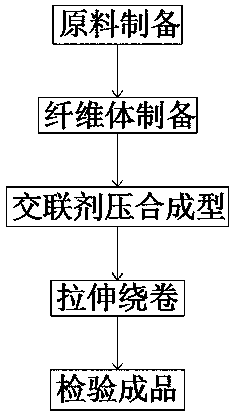

Silk composite fabric production method

InactiveCN110438613ATightly wovenImprove mechanical propertiesSucessive textile treatmentsYarnCellulose acetateWear resistance

The invention relates to the technical field of garment production and discloses a silk composite fabric production method. The method includes steps: S1, raw material selection and weighing; S2, yarnblending for filamentation; S3, blending processing; S4, deburring soaking treatment; S5, washing treatment; S6, finished product cutting and packaging. By the silk composite fabric production method, improvement of a composite fiber material of a composite fabric can be realized to improve mechanical properties of the composite fabric while softness and comfort of the composite fabric are guaranteed, and wear resistance and corrosion resistance of the fabric are improved by adding of natural hemp fibers, cellulose acetate fibers and soybean fibers into the composite fabric, so that tensile resistance, wear resistance and corrosion resistance are greatly improved while softness of the fabric is guaranteed, a utilization range of the silk composite fabric is expanded, and the service lifeof the silk composite fabric is prolonged.

Owner:杭州丝绸之路文化艺术有限公司

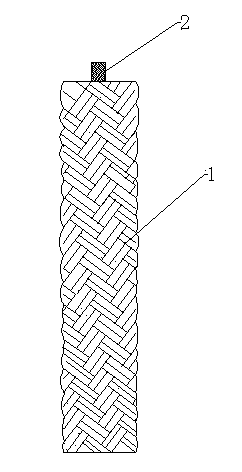

Vinylon fiber compound rope and preparation method thereof

The invention discloses a vinylon fiber compound rope and a preparation method thereof. The compound rope includes a rope skin knitted by a part of S twist direction vinylon fiber strands and another part of Z twist direction vinylon fiber strands, and a rope core that is disposed in the rope skin and is a complex of vinylon fiber. The preparation process is reasonable, and the vinylon fiber compound rope has sunlight resistance and high strength performance.

Owner:TAIAN ROPE NET PLASTIC

A kind of basalt fiber grid cloth reinforced composite material and preparation method thereof

The invention discloses a basalt fiber grid cloth reinforced composite material and a preparation method thereof, and relates to the field of new materials. This material can be used to replace steel and aluminum for the interior decoration of automobiles and new energy vehicles, as well as part of the body frame and the outer shell of the vehicle to reduce the weight of the vehicle. The basalt fiber mesh cloth reinforced composite material includes the following components: basalt fiber mesh cloth 500-1500g / m 2 , PC resin 20-80 parts, ABS resin 80-20 parts, antioxidant 0-1 part, lubricant 0-2 parts, mineral oil 0-200ml, coupling agent 0-5 parts.

Owner:NANCHONG XUYANG PLASTIC MFG CO LTD

Novel aluminum silicate fiber compound rope and preparation method thereof

InactiveCN103422374AReasonable workmanshipTightly wovenRope making machinesYarnFiberAluminum silicate

The invention discloses a novel aluminum silicate fiber compound rope and a preparation method thereof. The novel aluminum silicate fiber compound rope comprises a rope skin and a rope core, wherein the rope skin is woven in a manner that one part of aluminum silicate belcotex fiber rope strand is twisted in an S-shaped direction and another part of aluminum silicate belcotex fiber rope strand is twisted in a Z-shaped direction. The rope core is an aggregation of aluminum silicate belcotex fibers. The novel aluminum silicate fiber compound rope has the advantages of reasonable process, high inflaming retarding fireproof performance, strength and safety, and wide application scope.

Owner:TAIAN ROPE NET PLASTIC

Stretch-proof textile fiber and manufacturing method thereof

The invention discloses a stretch-proof textile fiber and a manufacturing method thereof. The textile fiber comprises more than two fiber bodies in identical specification, and a cross-linking agent is extruded among contact surfaces of opposite sides of the fiber bodies. Each fiber body comprises an outer coating, a filler layer, acrylic fiber monomers and a deformation frame, wherein the acrylicfiber monomers are distributed on the outer wall of the deformation frame. The manufacturing method of the textile fiber includes steps: raw material preparation, to be more specific, preparing the deformation frames, the outer coatings, the filler layers and the acrylic fiber monomers according to components, wherein a content ratio of polyurethane elastomers in the deformation frames to graphene is 1:50, and a content ratio of polyacrylonitrile in the acrylic fiber monomers to a curing agent is 1:1.5. On the basis of acrylic fibers, the deformation frames are constructed inside to keep stability and thermal conductivity, and favorable breathability and wrapping effects of fabrics are achieved; externally, integral cross-linking stability is guaranteed through filler and coatings, and compactness in weaving of the textile fiber is improved.

Owner:滁州霞客环保色纺有限公司

Double-layer fire-fighting water hose production technology

The invention provides a double-layer fire-fighting water hose production technology. The double-layer fire-fighting water hose production technology comprises the following steps that firstly, a material is selected and added into a reacting furnace to be smelted, a colloidal mixture is formed and then introduced into an extruding machine, extruding and cooling are conducted, and a cylindrical lining layer and a cylindrical cladding layer are formed; secondly, warp-weft knitting is conducted by adopting a two-shuttle circular knitting machine, warp yarn hole position groups are arranged on circular-ring cloth of a circular knitting machine workbench, warp yarn is threaded on the warp yarn hole position groups every other two positions or every other multiples of two positions, two shuttles on the circular knitting machine pull weft yarn of the two shuttles to move along shuttle running rails simultaneously, and bipartite yarn discs of the two shuttles conduct twisting by adopting a two-upper two-lower mode; and thirdly, the made lining layer is sleeved with a knitting layer, the cladding layer is coated with a bonding agent, and the knitting layer is wrapped in the cladding layer.According to the double-layer fire-fighting water hose production technology, knitting is more tight, the pressure bearing effect is better after water is introduced, bursting can not occur, a double-layer fire-fighting water hose can adapt to various fire scenes with complex conditions, and damage is not prone to occurring.

Owner:QUANZHOU SANXING FIRE FIGHTING EQUIP

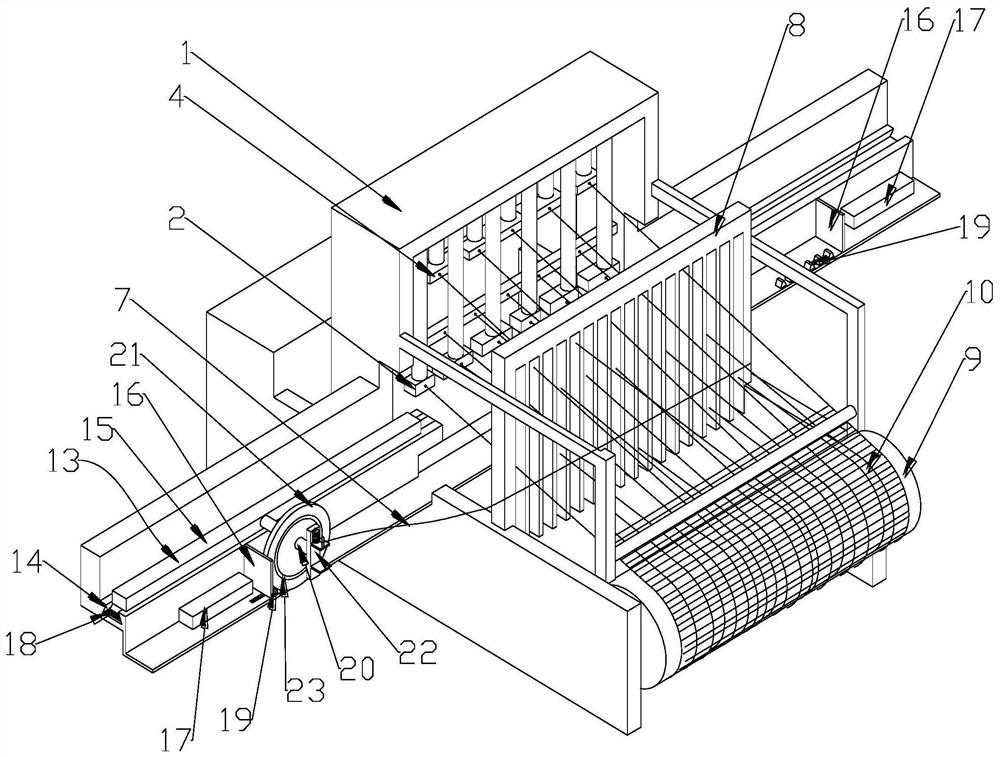

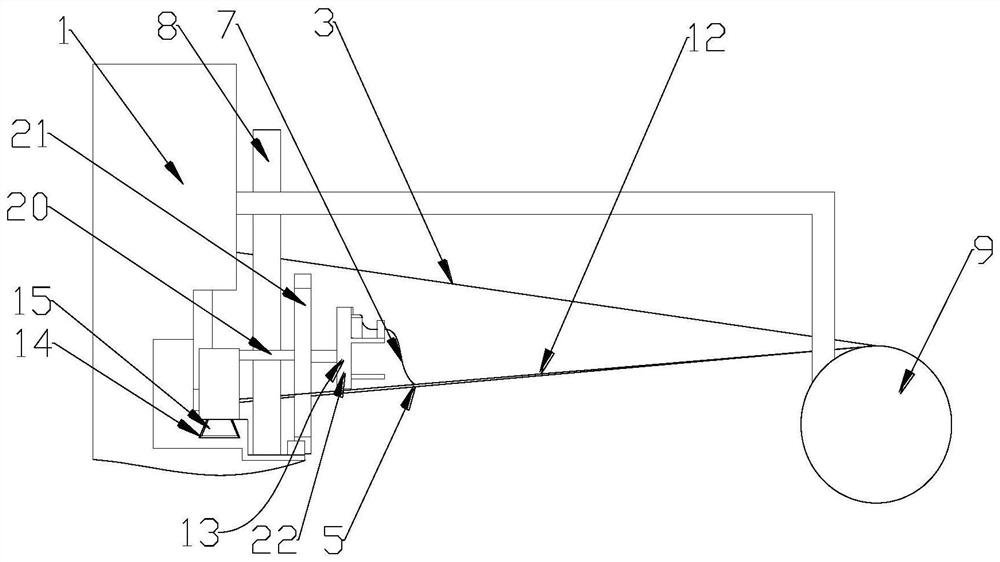

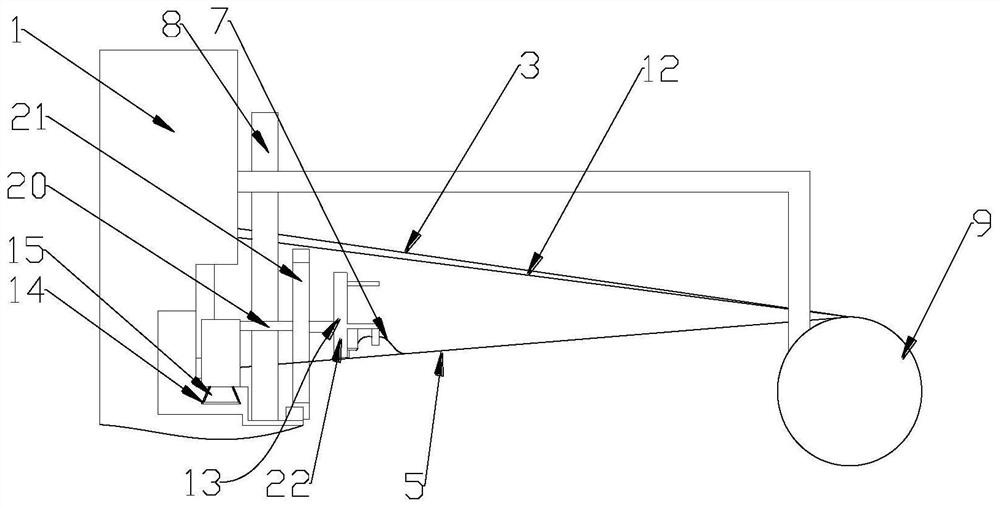

Weaving machine for textile fabric processing

ActiveCN113445180AGuaranteed hardnessGuaranteed DensityLoomsMulti-ply fabricsLap jointMechanical engineering

The invention relates to the technical field of textile machines, and provides a weaving machine for textile fabric processing. The weaving machine comprises a rack; a first moving frame is arranged on the rack in a lifting manner; first longitudinal threads penetrate through the first moving frame; a second moving frame is arranged on the rack in a lifting manner; second longitudinal threads penetrate through the second moving frame; the sliding direction of the second moving frame is opposite to that of the first moving frame; a comb plate is arranged on the rack in a sliding manner; the first longitudinal threads, the second longitudinal threads and transverse threads are tightly woven; a stepping roller is rotationally arranged on the rack and used for winding woven cloth; a middle moving frame is arranged on the rack in a sliding mode, located between the first moving frame and the second moving frame and used for arranging middle longitudinal threads in a penetrating mode; a shuttling frame is arranged on the rack in a sliding mode; and the shuttling frame is used for driving the transverse threads to be in lap joint between the first longitudinal threads and the middle longitudinal threads, or the shuttling frame is used for driving the transverse threads to be in lap joint between the second longitudinal threads and the middle longitudinal threads. According to the technical scheme, the problem that the hardness, the service life and the compactness of a woven fabric cannot be guaranteed at the same time by spinning equipment in related technologies is solved.

Owner:河北柏立信家纺股份有限公司

Safety fence rope and manufacturing technology thereof

InactiveCN103422375AReasonable structureGood anti-collision performanceTextile cablesEngineeringPolypropylene fiber

The invention discloses a safety fence rope and manufacturing technology thereof. The safety fence rope comprises a rope cover and a polypropylene fiber rope core, wherein the rope cover is formed by weaving a part of galvanized polypropylene fiber strands twisted in the S direction and the other part of galvanized polypropylene fiber strands twisted in the Z direction, and the polypropylene fiber rope core is arranged in the rope cover. The safety fence rope is reasonable in structure, safe, reliable, good in anti-collision performance, wide in range of application and capable of being widely used for safety protection of expressways and roads of mountain regions and scenic spots.

Owner:TAIAN ROPE NET PLASTIC

Mask ear hanging belt and weaving process thereof

ActiveCN113529263ASoft textureIncrease elasticityWarp knittingProtective garmentEngineeringWeft yarn

The invention discloses a mask ear hanging belt and a weaving process thereof. The mask ear hanging belt is used for being fixed to the two sides of a mask; the mask ear hanging belt comprises warp yarns and weft yarns, and the warp yarns and the weft yarns are interwoven to form a rope-belt-shaped structure; the warp yarns comprise upper warp yarns located in the middle and lower warp yarns located in the middle and staggered with the upper warp yarns, first side warp yarns positioned on one sides of the upper warp yarns and the lower warp yarns, and second side warp yarns positioned on the other sides of the upper warp yarns and the lower warp yarns; and the weft yarns are interwoven with the upper warp yarns and the lower warp yarns to form a cross weaving shape; and the warp yarns and the weft yarns are polyamide yarns; and the mask ear hanging belt and the weaving process thereof can improve the comfort of wearing the mask for a long time.

Owner:广州市唯宾织带有限公司

Polysulfonamide fiber compound rope and manufacturing method thereof

InactiveCN103572626ATightly wovenReasonable processing technologyTextile cablesThermal contractionEngineering

The invention discloses a polysulfonamide fiber compound rope and a manufacturing method thereof. The polysulfonamide fiber compound rope comprises a rope surface and a rope core, wherein the rope surface is formed by weaving part of polysulfonamide fiber strands in the S twist direction and the other part of the polysulfonamide fiber strands in the Z twist direction, the rope core is arranged inside the rope surface, the rope surface is an outer sleeve formed by weaving the polysulfonamide fiber strands which are composed of a plurality of twisting polysulfonamide fiber filaments, the surfaces of the polysulfonamide fiber filaments are processed, and the rope core is an aggregate of polysulfonamide fiber filaments. The polysulfonamide fiber compound rope is woven compactly and has reasonable processing technologies, good heat resistance, good thermo-oxidative aging resistance and small thermal contraction.

Owner:TAIAN ROPE NET PLASTIC

Heatproof stainless steel fiber rope and production method

InactiveCN104452091AGuaranteed SolderabilityImprove strength propertiesBraidMetallurgyHeat resistance

The invention discloses a heatproof stainless steel fiber rope and a production method thereof. The heatproof stainless steel fiber rope comprises rope sheath which is braided by a part of S-twist-direction heatproof stainless steel fiber strand and another part of Z-twist-direction heatproof stainless steel fiber strand, and a rope core arranged in the rope sheath, and the rope core is arranged as a heatproof stainless steel fiber complex. The heatproof stainless steel fiber rope has the advantages of compact braiding and reasonable technology, and the product has the advantages of good heat resistance, strong chemical corrosion resistance and high strength performance.

Owner:TAIAN ROPE NET PLASTIC

Static sub-conductor fiber rope and manufacturing method thereof

The invention discloses a static sub-conductor fiber rope and a manufacturing method of the static sub-conductor fiber rope. The fiber rope comprises a rope skin and a rope core, wherein the rope skin is formed by weaving part of static sub-conductor fiber rope strands in the S twist direction and part of static sub-conductor fiber rope strands in the Z twist direction. The rope core is arranged in the rope skin and is an integration body of high-strength terylene polyester fiber filaments. The rope skin is arranged to be an outer sleeve body which is formed by weaving the multiple static sub-conductor fiber rope strands formed by twisting multiple static sub-conductor fiber monofilaments with surface treatment. The weaving is compact, the strength is improved, and the fiber rope has good electrical conduction and an-explosion properties.

Owner:TAIAN ROPE NET PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com