Polymer synthetic fiber rope and processing method thereof

A synthetic fiber and polymer technology, used in textile cables, textiles and papermaking, etc., can solve the problems of poor wear resistance, high temperature corrosion resistance, weak fatigue resistance and bearing capacity, and short service life of ropes. Fatigue resistance and good bearing capacity, long service life, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

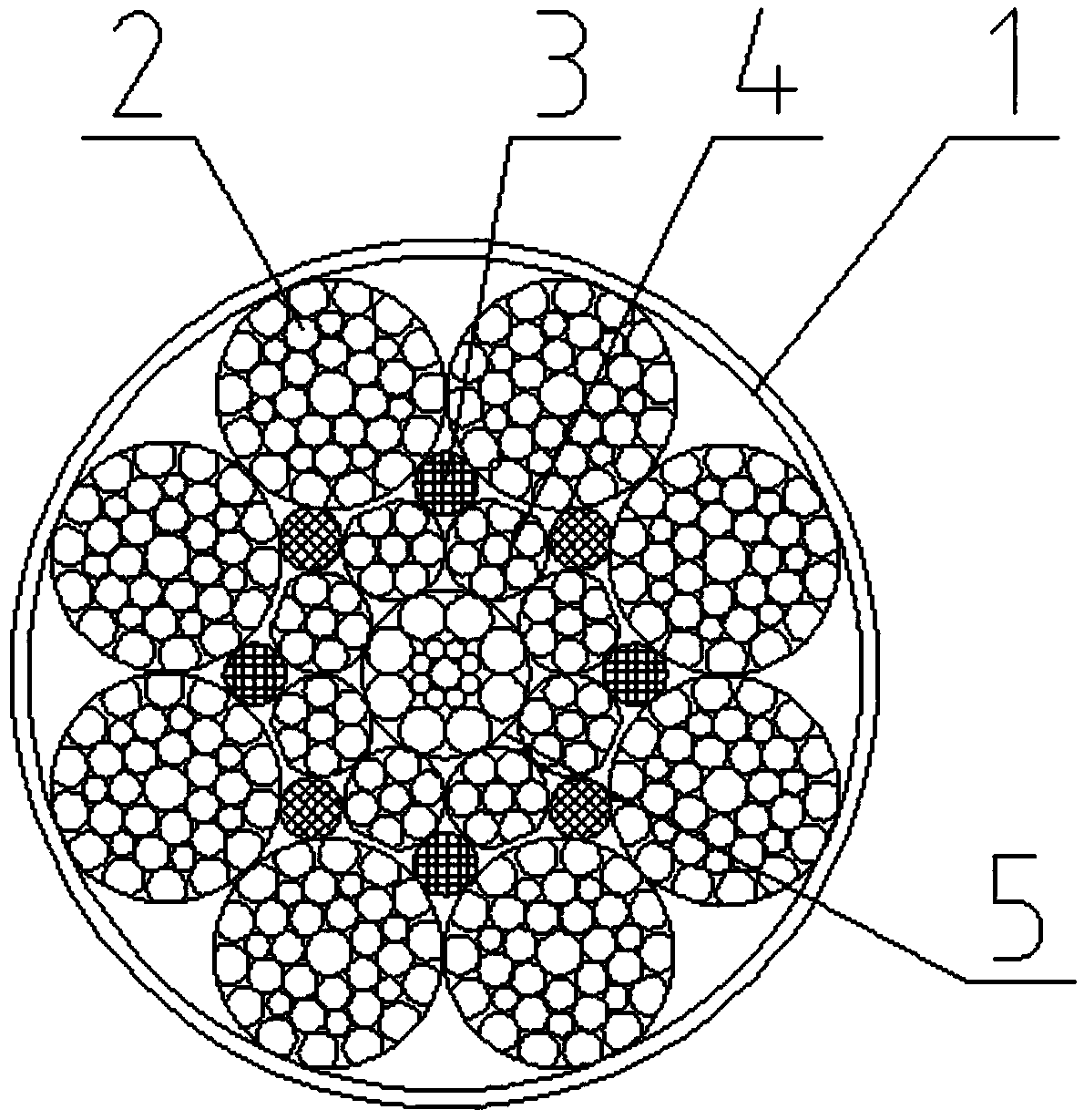

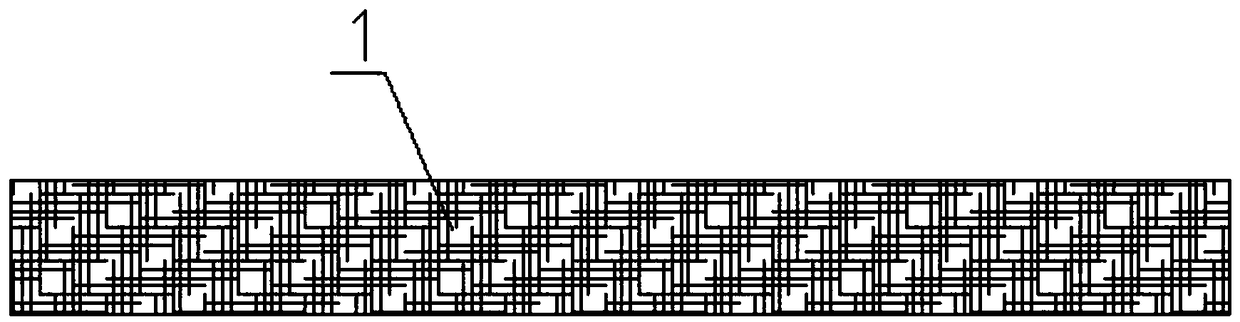

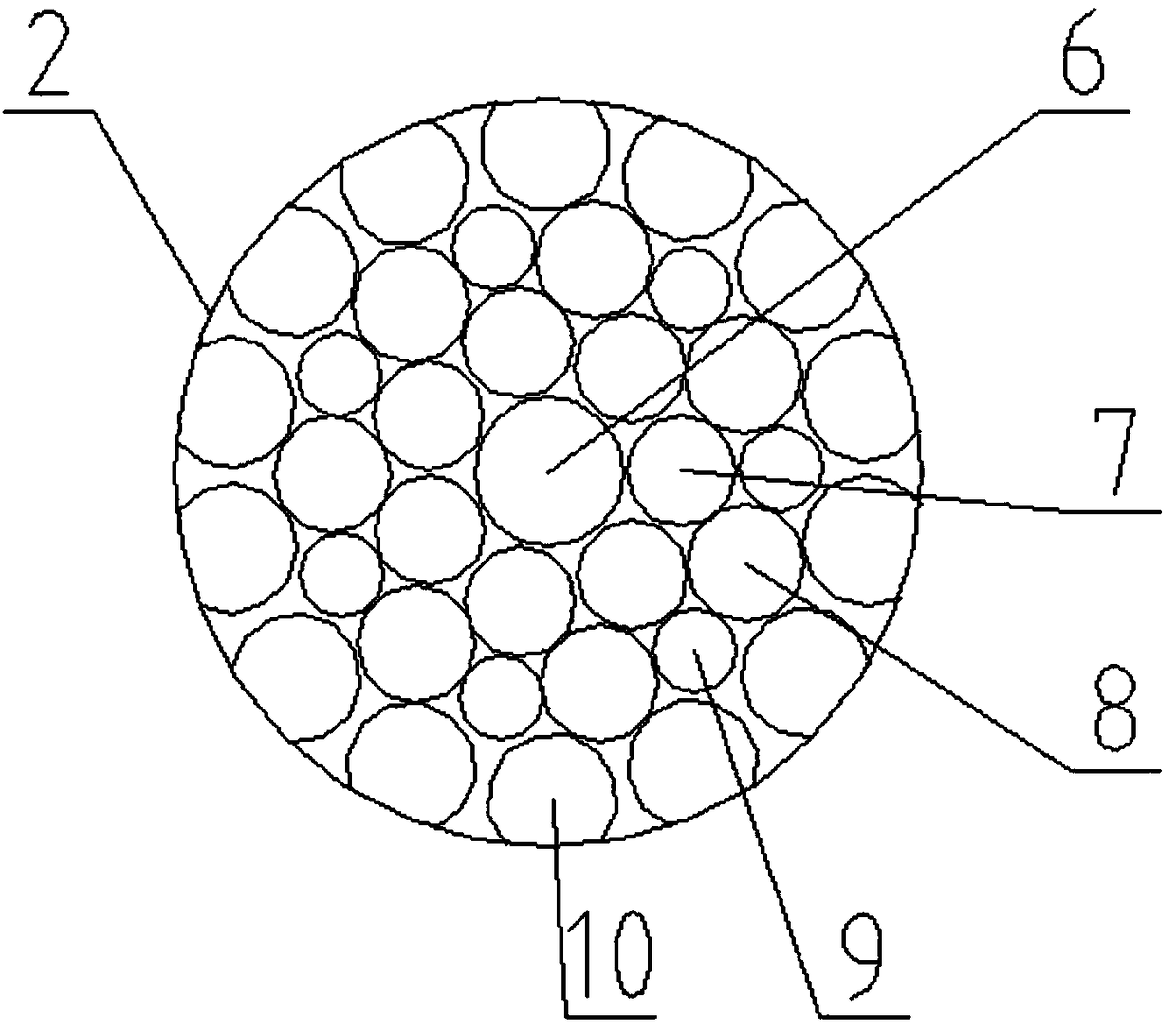

[0032] Such as Figure 1-Figure 4 As shown, a polymer synthetic fiber rope includes a coated fiber layer 1, an outer layer strand 2, an auxiliary layer strand 3, and an inner main strand 4, and the outer layer strand 2 is arranged in the coated fiber layer 1 , polyester fibers 10 are arranged in the outer layer strand 2, polyamide fibers 8 are arranged inside the polyester fibers 10, polyacrylonitrile fibers 9 are arranged between the polyamide fibers 8, and polyacrylonitrile fibers 9 The inner side is provided with polyethylene fiber 7, the inner side of the polyethylene fiber 7 is provided with polytetrafluoroethylene fiber 6, the inner side of the outer layer strand 2 is provided with the auxiliary layer strand 3, and the inner side of the auxiliary layer strand 3 is provided with a The inner layer main strand 4 is provided with a central strand 5 inside the inner layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com