Static sub-conductor fiber rope and manufacturing method thereof

A subconductor and fiber rope technology, applied in the rope field, can solve the problems of damage to electronic components, explosion accidents, fires, etc., and achieve the effects of good electrical conductivity and explosion-proof performance, compact weaving, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

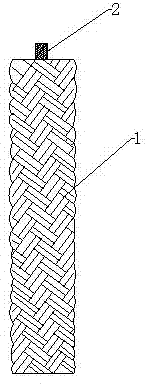

Image

Examples

preparation example Construction

[0016] A preparation method of an electrostatic subconductor fiber rope, comprising the following steps:

[0017] (1) Material selection: use surface-treated electrostatic subconductor fiber filament as the rope sheath material, and its specification is 840D-3000D, and use high-strength polyester polyester fiber filament as the rope core material, and its specification is 840D-3000D;

[0018] (2) Paralleling: use m electrostatic subconductor fiber filaments and combine them into one strand;

[0019] (3) Twisting: the parallel electrostatic subconductor fiber filaments are twisted by a twisting machine to make electrostatic subconductor fiber strands;

[0020] (4) Pre-weaving: The electrostatic subconductor fiber strands twisted by the twisting machine are pre-woven on the automatic pre-looming machine into a bobbin that meets the spindle size of the high-speed weaving machine for weaving;

[0021] (5) Heat setting: The rope core 2 of the twisted high-strength polyester fiber ...

Embodiment 1

[0025] A preparation method of an electrostatic subconductor fiber rope comprises the following steps:

[0026] 1. Selection of raw materials: use surface-treated electrostatic subconductor fiber filaments as the rope sheath material, and its specification is 840 D, and use high-strength polyester polyester fiber filaments as the rope core material, and its specification is 840D;

[0027] 2. Parallel line: 6 electrostatic subconductor fibers are combined into one strand for parallel line;

[0028] 3. Twisting: After paralleling, the electrostatic subconductor fiber filaments are twisted by a 722 twisting machine to make electrostatic subconductor fiber strands. The transmission belt of the twisting machine is tight and tight, and each filament must be controlled by a tension regulator. , measure its rotation speed and twist regularly, and the twist depends on the size of the rope strands;

[0029] 4. Pre-weaving: The strands twisted by the twisting machine are pre-woven on th...

Embodiment 2

[0033] A preparation method of an electrostatic subconductor fiber rope comprises the following steps:

[0034] 1. Selection of raw materials: use surface-treated electrostatic subconductor fiber filaments as the rope sheath material, and its specification is 3000D, and use high-strength polyester polyester fiber filaments as the rope core material, and its specification is 3000D;

[0035] 2. Parallel line: 8 electrostatic subconductor fibers are combined into one strand for parallel line;

[0036] 3. Twisting: After paralleling, the electrostatic subconductor fiber filaments are twisted by a 722 twisting machine to make electrostatic subconductor fiber strands. The transmission belt of the twisting machine is tight and tight, and each filament must be controlled by a tension regulator. , measure its rotation speed and twist regularly, and the twist depends on the size of the rope strands;

[0037] 4. Pre-weaving: The strands twisted by the twisting machine are pre-woven on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com