Micro-miniature compressed air energy-storage system combining compressed air and hydraulic pressure

A technology of compressed air energy storage and compressed air, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc. It can solve problems such as harsh geographical conditions, not meeting the requirements of green energy development, and limiting the scope of application, etc., and the realization method is simple , constant pressure effect is remarkable, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

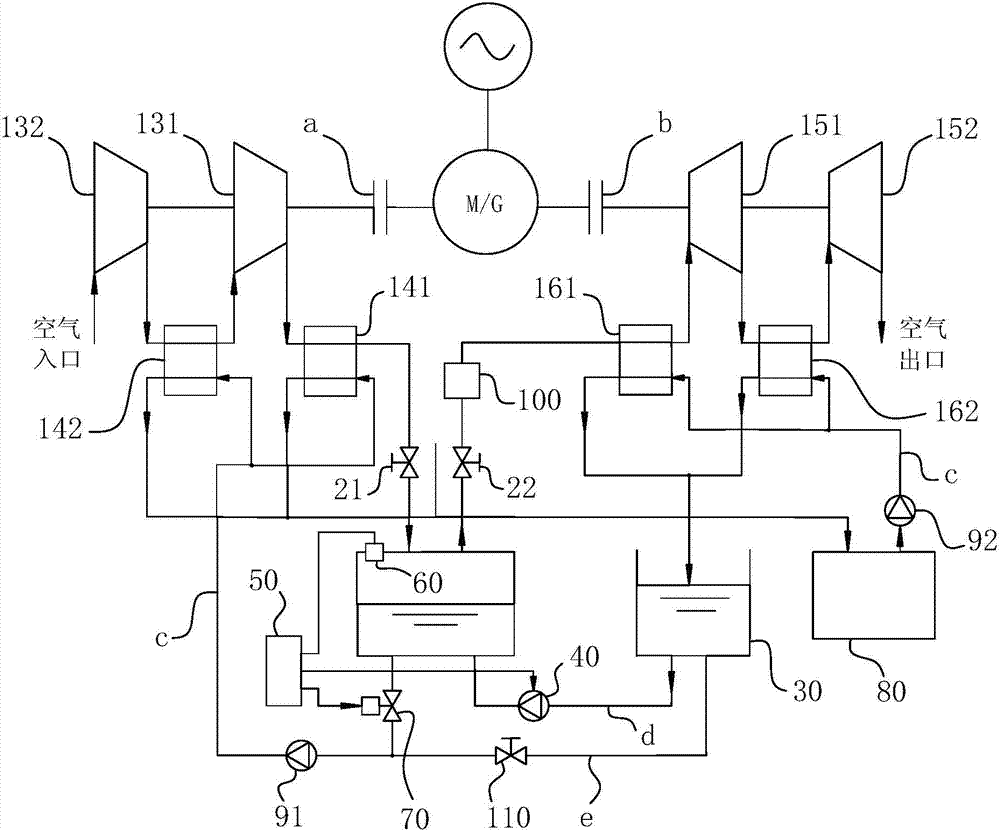

[0025] For ease of understanding, combined here figure 1 Concrete testing device of the present invention and operation process thereof are further described as follows:

[0026] In fact, the main pipeline layout of the system is initially divided by the inlet and outlet pipelines c and d on the liquid storage tank 30. The liquid outlet pipeline d of the liquid storage tank 30 is relatively simple, and only passes The pump 40 is enough to enter the gas storage tank 10; while the liquid inlet pipeline c of the liquid storage tank 30 is demarcated from the liquid outlet pipeline d by the gas storage tank 10, specifically through the flow control valve 70, the first A booster pump 91 and heat absorbers arranged in parallel enter into the high-temperature heat storage tank 80, and then flow from the high-temperature heat storage tank 80 into the liquid storage tank 30 through the heaters arranged in parallel to complete its overall pipeline structure. The supply line e is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com