A kind of oil sump of automobile engine

A technology of automobile engine and oil pan, which is applied in the direction of engine lubrication, engine components, machine/engine, etc., to reduce the difficulty of assembly and disassembly, improve the effect of cushioning and energy absorption, and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

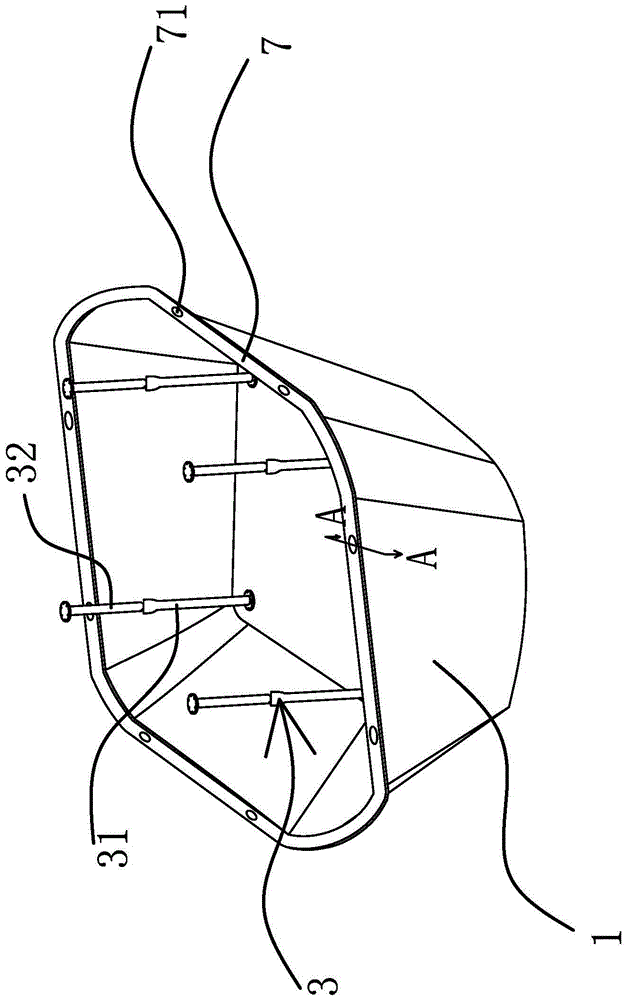

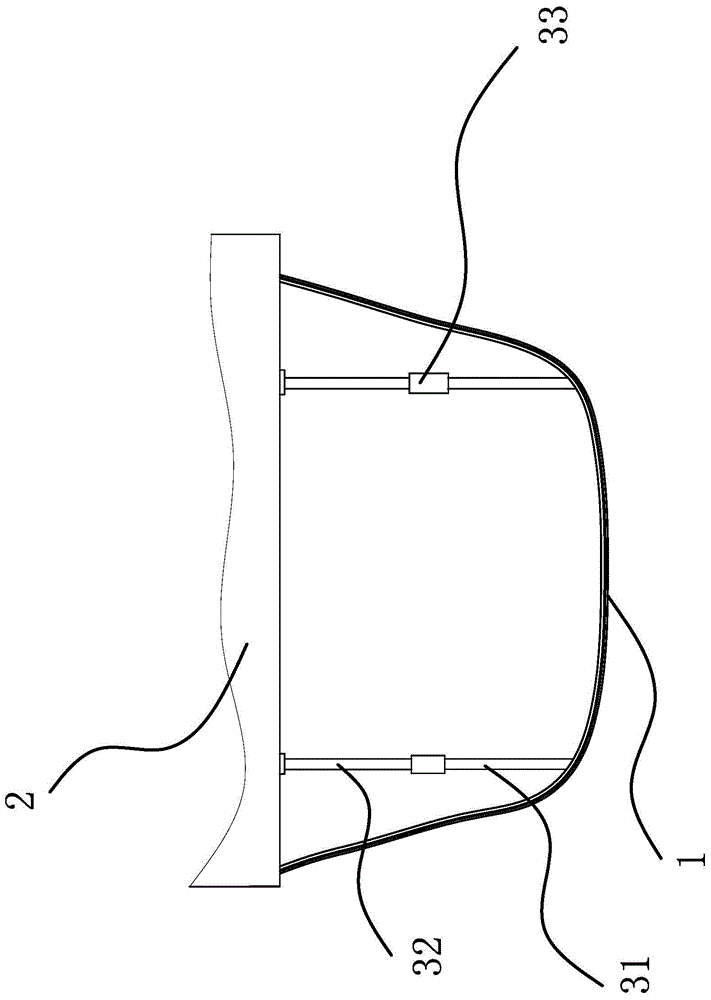

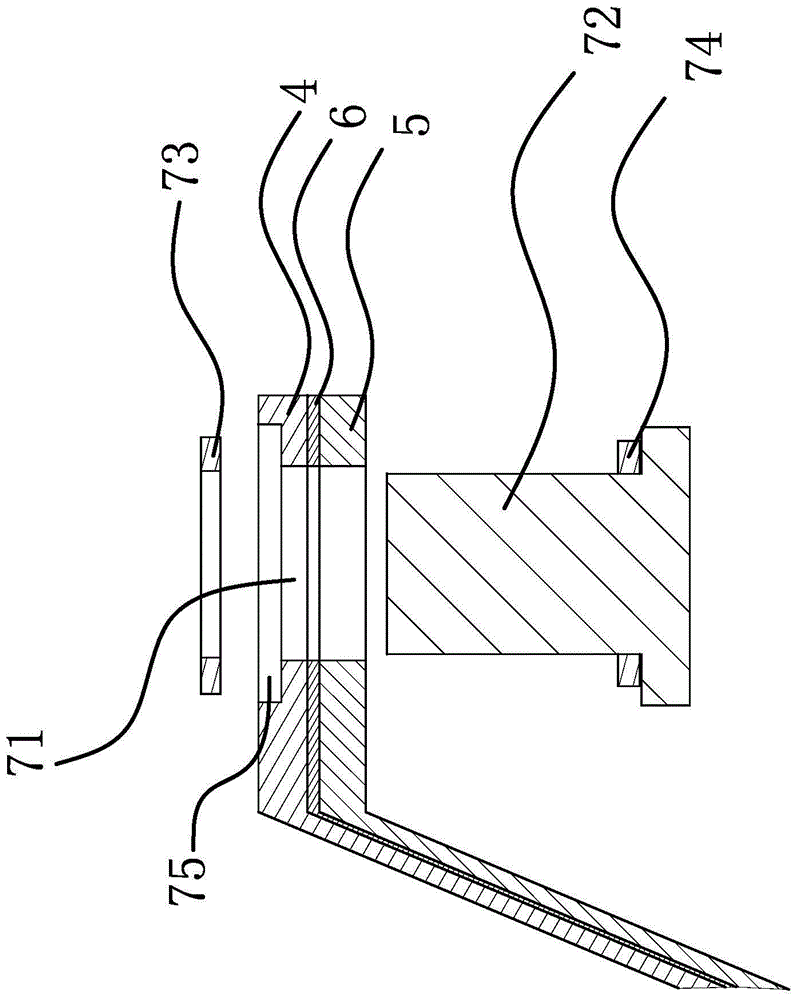

[0030] Such as figure 1 , figure 2 , Figure 4 and Figure 5 Shown, a kind of oil pan of automobile engine, this oil pan comprises a flexible shell 1 that is connected at the lower end of engine block 2, and the upper end of shell 1 is connected with the lower end of engine block 2, and the bottom of shell 1 Also be provided with a support structure 3 that can support the bottom of the housing 1 between the bottom and the engine block 2, the support structure 3 includes several support rods 31 that are fixedly connected at the bottom of the housing 1 and are fixed with the engine block 2. Connected support rod two 32, a living hinge 33 is arranged between the upper end of the support rod one 31 and the lower end of the support rod two 32, and the basic shape and size of the housing 1 are kept in the process of automobile bumping and mechanical vibration, and the living hinge 33 A degree of freedom in the horizontal direction can be provided for the shell 1, so that the she...

Embodiment 2

[0034] Such as Figure 6 As shown, the content of this embodiment is roughly the same as that of Embodiment 1, except that the support structure 3 includes several elastic metal strips 34, and the two ends of the metal strips 34 are fixedly connected to the bottom of the housing 1 and the cylinder body 2 respectively. , the elastic metal strip 34 can maintain the basic shape and size of the shell 1, and can elastically deform when an impact occurs, so that the shell 1 can be cushioned, and the metal strip 34 can also restore the shell after the shell 1 is impacted 1 for the original shape.

[0035] The working principle of the present invention is: in order to improve the shape of the oil pan with traditional rigid structure, which has poor cushioning effect and is prone to rupture when it is hit, the shell 1 of the oil pan of the engine is made of flexible material. Through the local deformation of the housing 1, it can have a good buffering effect. In order to maintain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com