Natural gas engine

A natural gas and engine technology, which is applied to the structure and structure of natural gas engines, can solve the problems of strict reliability and durability requirements of spark plugs, limited degree of lean mixture combustion, unstable combustion and flame propagation, etc., and achieves accelerated initial combustion. speed, widening the lean limit, reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

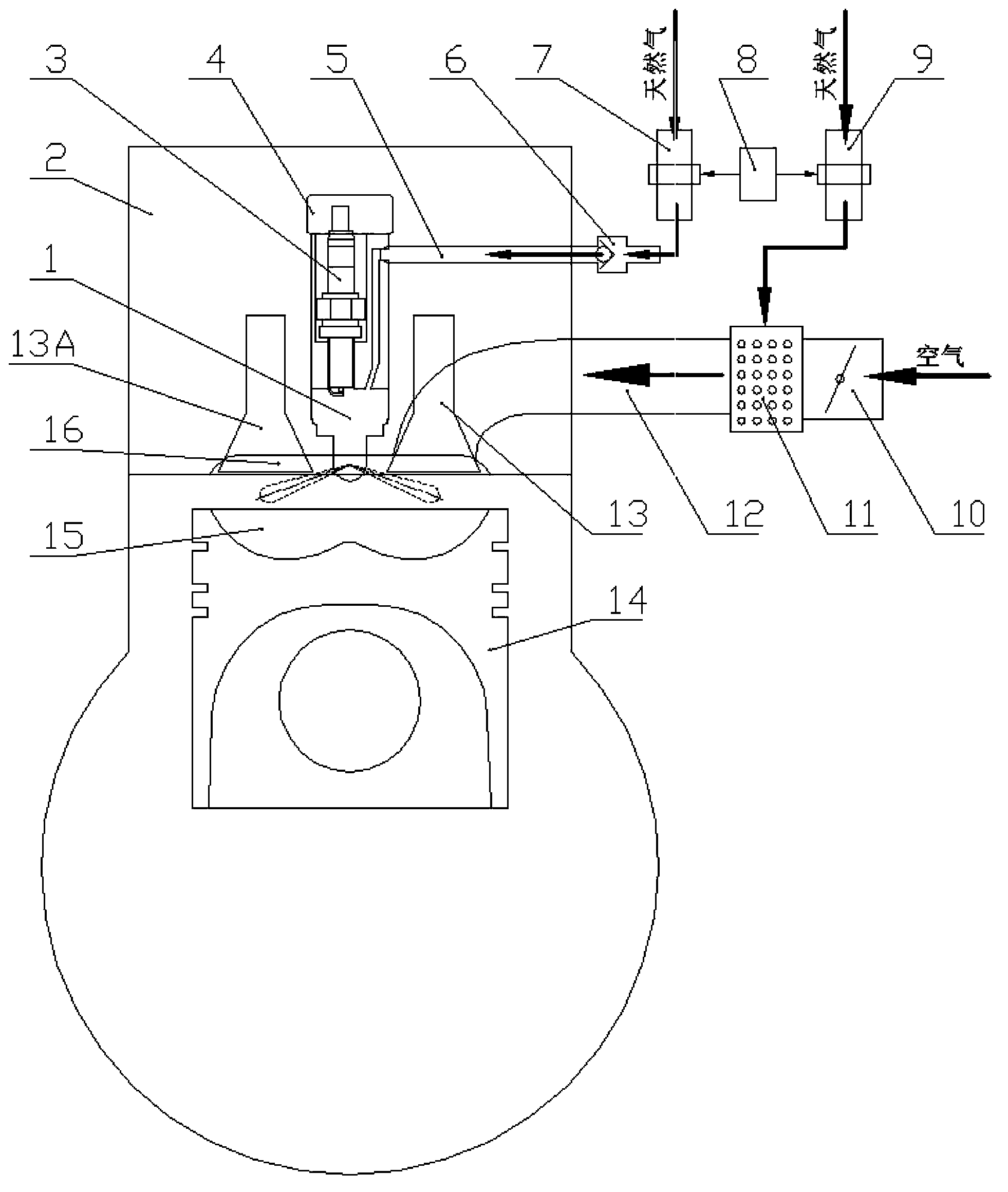

[0020] The natural gas engine of the present invention adopts the flame injection technology (FIS) on the basis of the existing diesel engine technology. After simple and unique structural design and transformation, it adopts the original flame injector structure through split air intake, Realize the sequential combustion mode in which the rich mixture gas is ignited by the spark, and then the lean mixture gas in the cylinder is ignited by the flame. Applied to natural gas engines, it can increase the excess air coefficient of the mixed gas in the cylinder of the natural gas engine, broaden the concentration range of the mixed gas; it can optimize the combustion in the cylinder of the engine, and achieve the lean mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com