Electromagnetic spool valve

A sliding valve, electromagnetic technology, applied in valve details, valve device, valve housing structure, etc., can solve problems such as sliding wear or sliding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

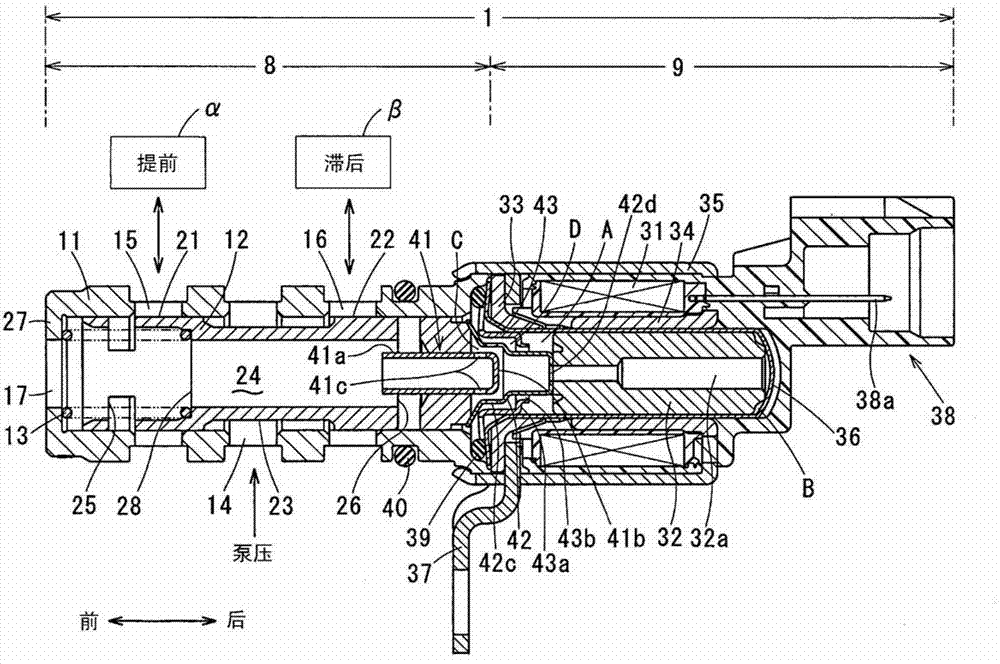

[0017] will combine Figure 1 to Figure 3 The first embodiment is explained. This embodiment is aimed at the OCV (Oil Control Valve) of the hydraulic VVT (Variable Valve Timing).

[0018] (Explanation of VVT)

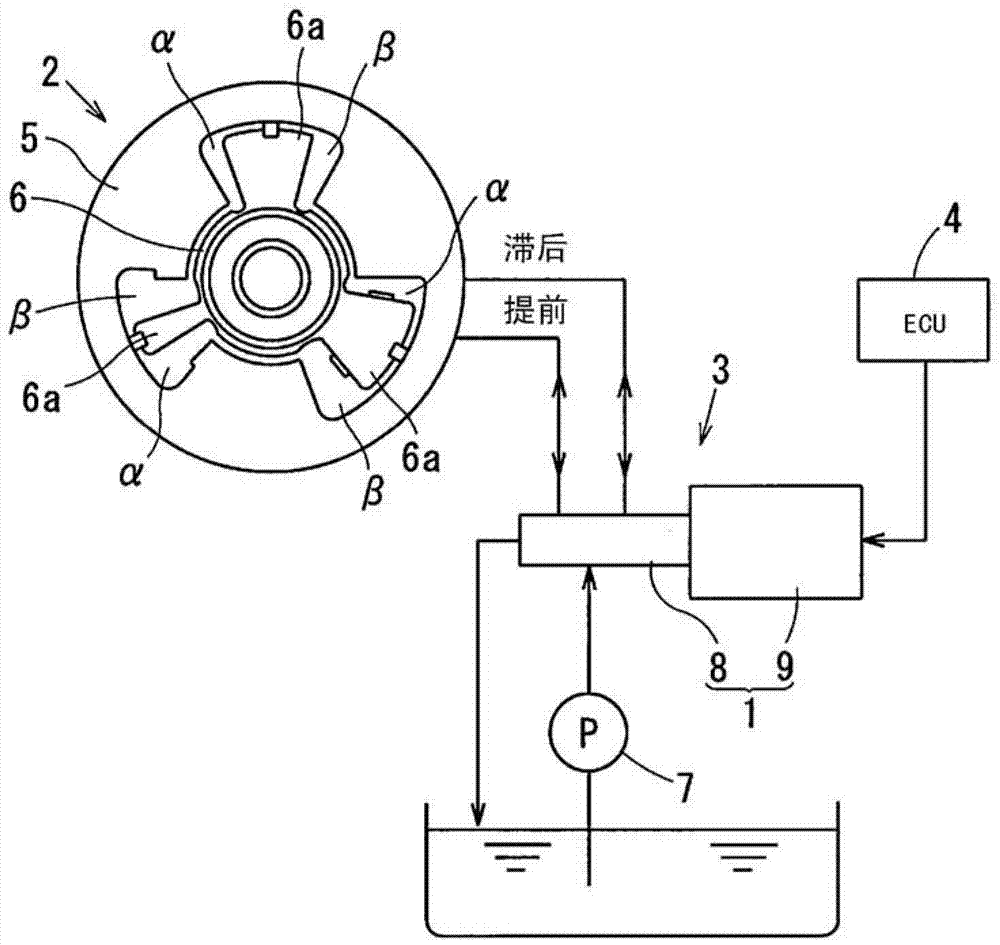

[0019] The VVT is installed in an engine for running a vehicle. VVT includes: (i) VCT (Variable Camshaft Timing Mechanism) 2, which is attached to the camshaft so as to steplessly change the advance angle of the camshaft and thus steplessly change the opening and closing timing of the valve; (ii) is performed using OCV1 Hydraulic circuit 3 for hydraulic control of VCT2; and (iii) ECU (Engine Control Unit) 4 for electrically controlling OCV1.

[0020] The VCT 2 includes a shoe housing 5 that rotates synchronously with a crankshaft of the engine, and a vane rotor 6 that rotates integrally with a camshaft. Driving the vane rotor 6 relative to the shoe housing 5 allows the camshaft to be changed on the advanced angle side or the retarded angle side.

[0021] The vane...

no. 2 example

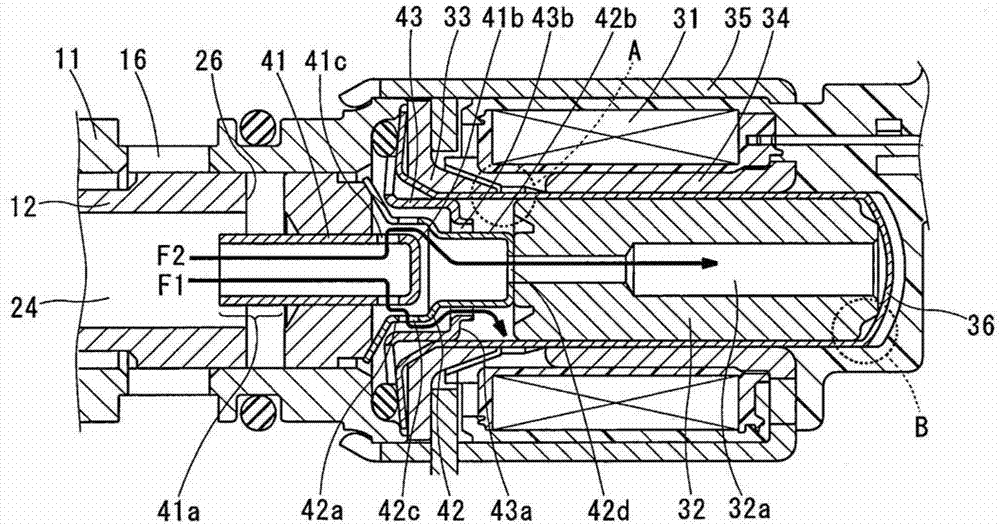

[0073] will be combined as follows Figure 4 The second embodiment is explained. The first embodiment provides an example in which the first space C and the in-plunger breathing hole 32a communicate with each other via the axial hole 42d. Alternatively, the second embodiment eliminates the axial hole 42d, and allows the high magnetic flux density portion A to communicate with the in-plunger breathing hole 32a.

[0074] Specifically, the rear end of the hollow shaft 42 is blocked; the radial recess 42e is disposed on the back of the hollow shaft 42; and the radial recess 42e extends radially. The high magnetic flux density portion A and the in-plunger breathing hole 32a communicate with each other via the radial recess 42e. This prevents foreign matter from reaching the low magnetic flux density portion B more surely.

[0075] The above embodiments provide the sleeve 11; alternatively, the spool valve 8 may be designed without the sleeve 11. That is, the spool 12 can be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com