Gas mixing device for completely-premixed combustion system

A combustion system, fully premixed technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of low combustion efficiency, unreasonable structure, unfavorable environmental protection, etc., achieve simple structure, improve combustion efficiency, and facilitate implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

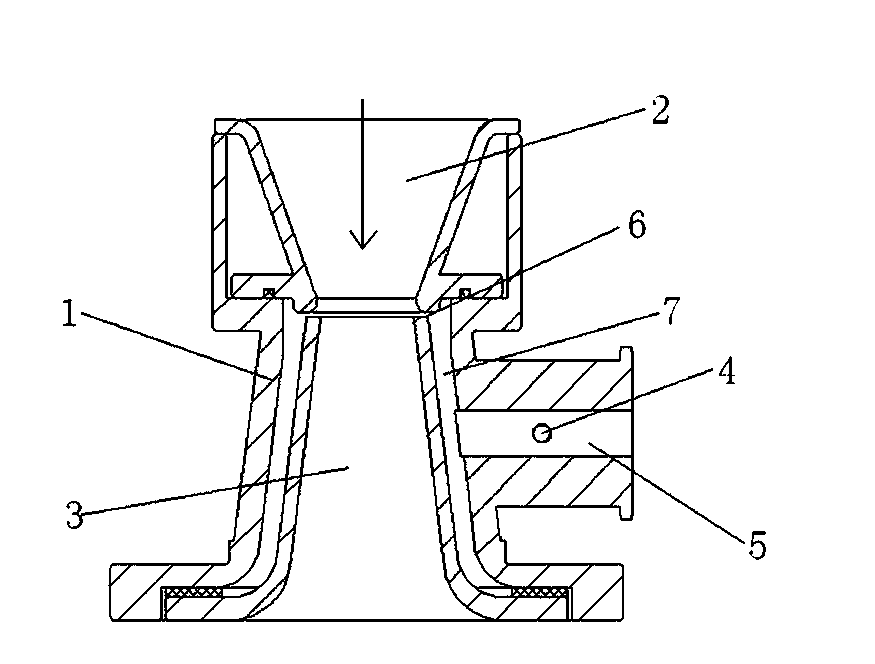

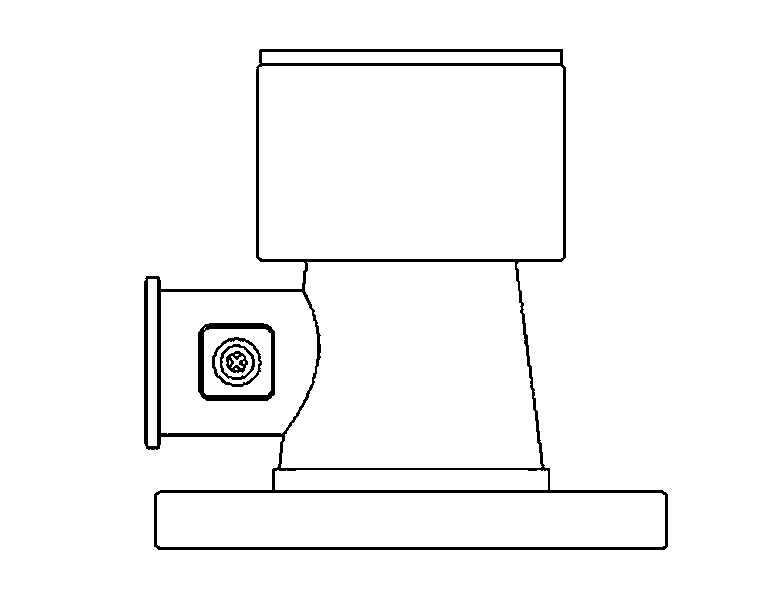

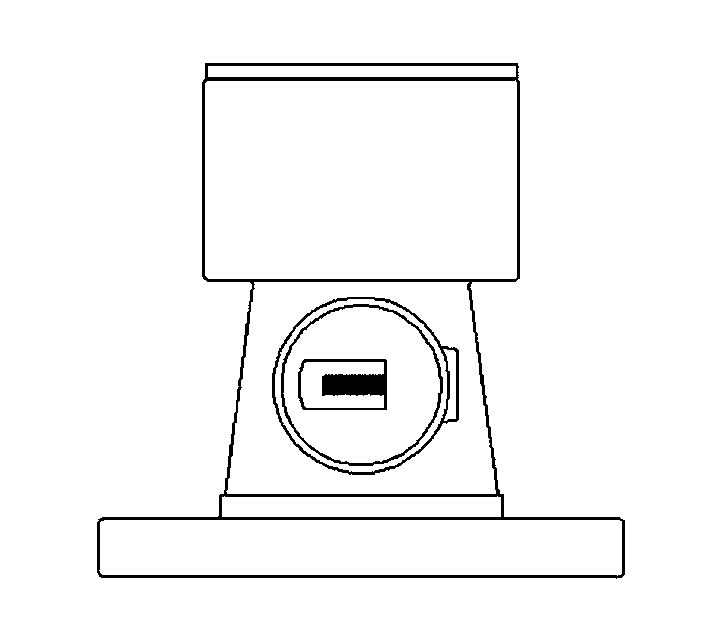

[0019] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a gas mixing device for a full premixed combustion system includes an outer cavity 1, an intake cavity 2, an air outlet cavity 3, a gas gas valve 4 and a gas source connecting pipe 5, the intake cavity and the gas outlet cavity. They are housed together in the outer cavity, the air intake cavity and the air outlet cavity are communicated, the air intake cavity is communicated with the air, and a gas channel is formed between the air intake cavity and the air outlet cavity, and the air intake cavity A first slit 6 is formed between the adjacent ends of the air outlet cavity, the end of the air inlet cavity and the outer peripheral side are sealedly connected to the outer cavity, and the air outlet cavity faces away from one end of the air inlet cavity A second slit 7 is formed between the outer peripheral side of the air outlet chamber and the inner peripheral side of the outer chamber, the first slit is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com