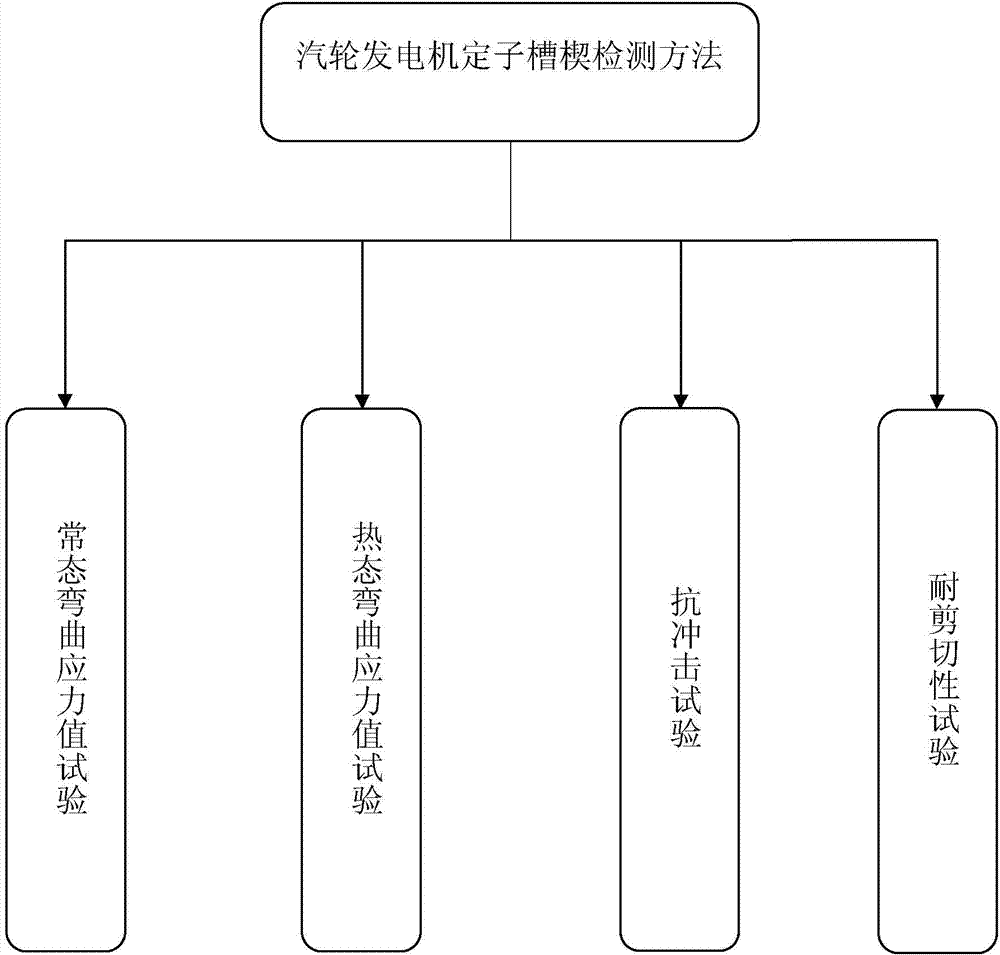

Method for detecting stator slot wedge of turbonator

A technology of a steam turbine generator and a detection method, which is applied in the directions of using a stable shear force to test the material strength, using a stable bending force to test the material strength, and a measuring device, etc. Into, coil out of the slot and other issues, to achieve the effect of improving the insurance factor and increasing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

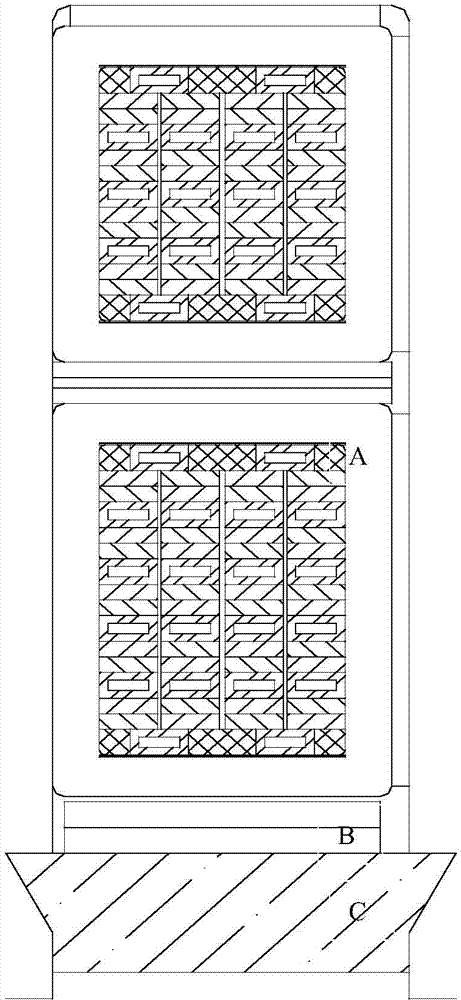

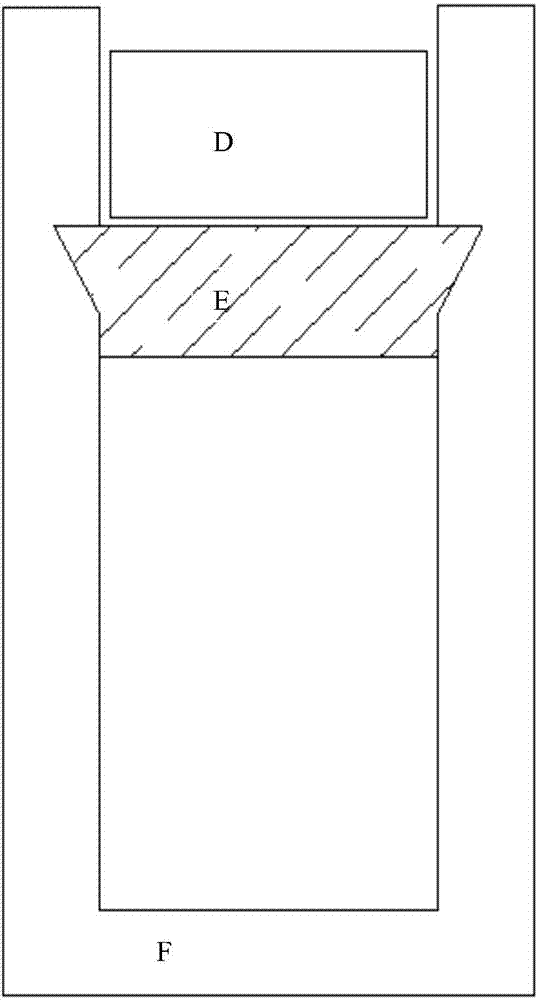

[0008] A turbogenerator stator wedge detection method, the detection method includes: normal bending stress value test, thermal bending stress value test, impact resistance test, shear resistance test, the specific content is as follows: a. normal bending stress value test: Steps: 1. Cut the sample on the stator wedge of the steam turbine generator according to the regulations, and process it into five samples on one side. The sample size is 80mm×10mm×4mm, and the processing error is ±0.2mm; 2. Adjust it well Span; 3. Place the sample symmetrically on the bending fixture support, and apply force at the center of the span until the test breaks. 4. Record and calculate the normal stress value, the formula σ f =3FL / 2bh 2 , where F is the applied force, in N; L is the span, in mm; b is the sample width, in mm; h is the sample thickness, in mm; The value should not be less than 340MPa; b. Hot bending stress value test: steps: 1. The sample is the same as specified in A; 2. Adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com