Experimental device for interaction between three-dimensional steel catenary riser and soil

A technology of steel catenary and experimental device, which is applied in the direction of measuring device, soil material test, material inspection product, etc., can solve the problems that the overall design and analysis cannot be used, and the actual riser engineering cannot be reflected, so as to promote theoretical research and Numerical analysis to ensure the effect of safe and reliable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

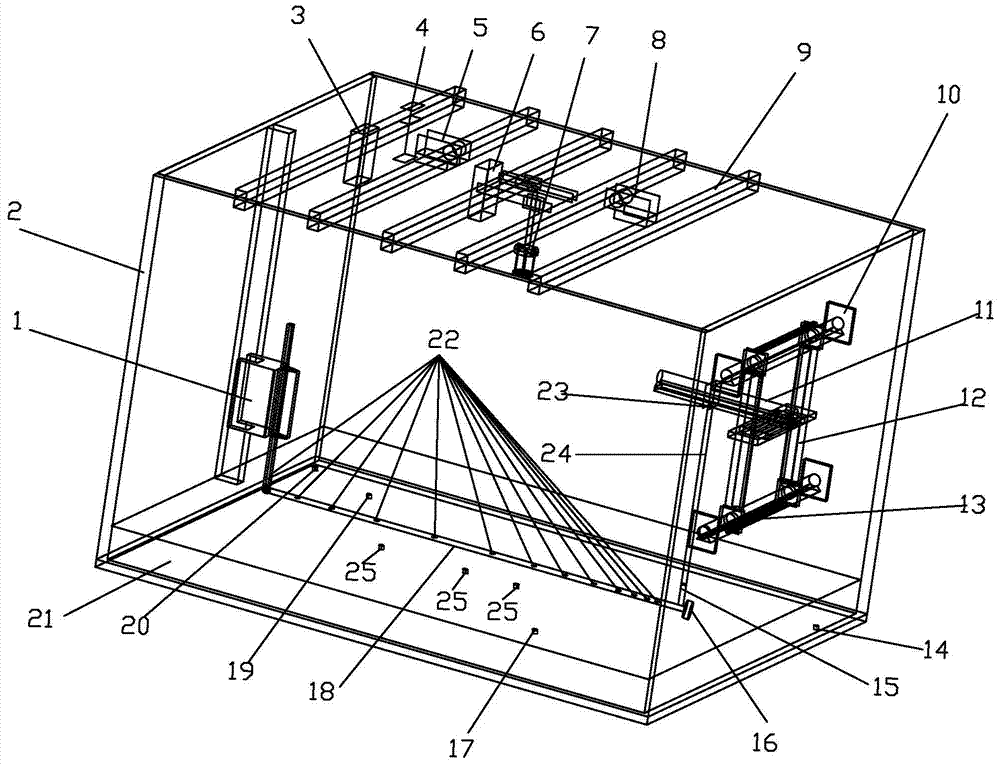

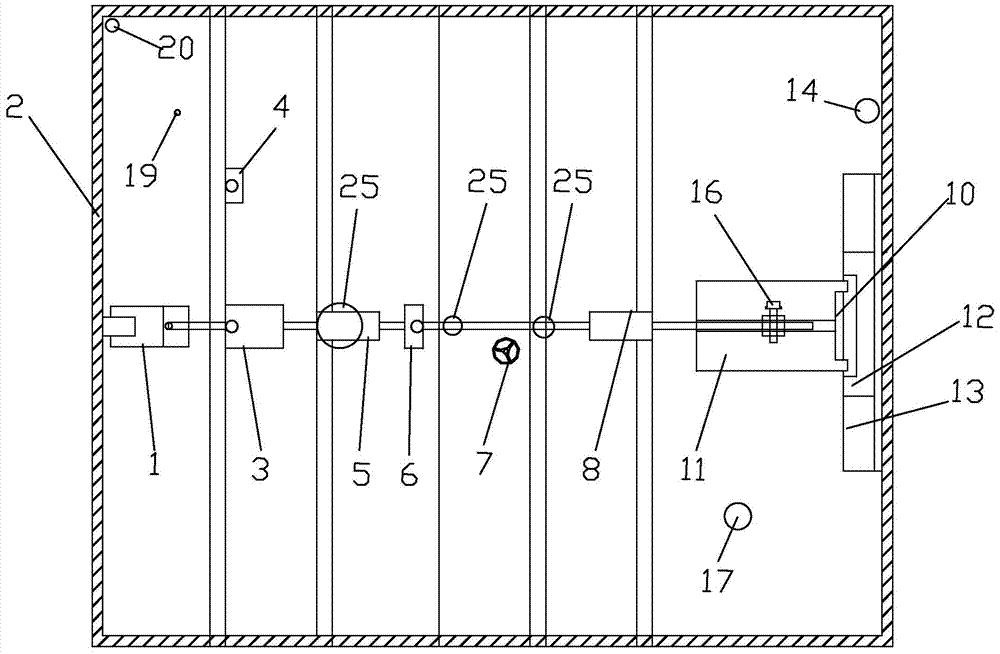

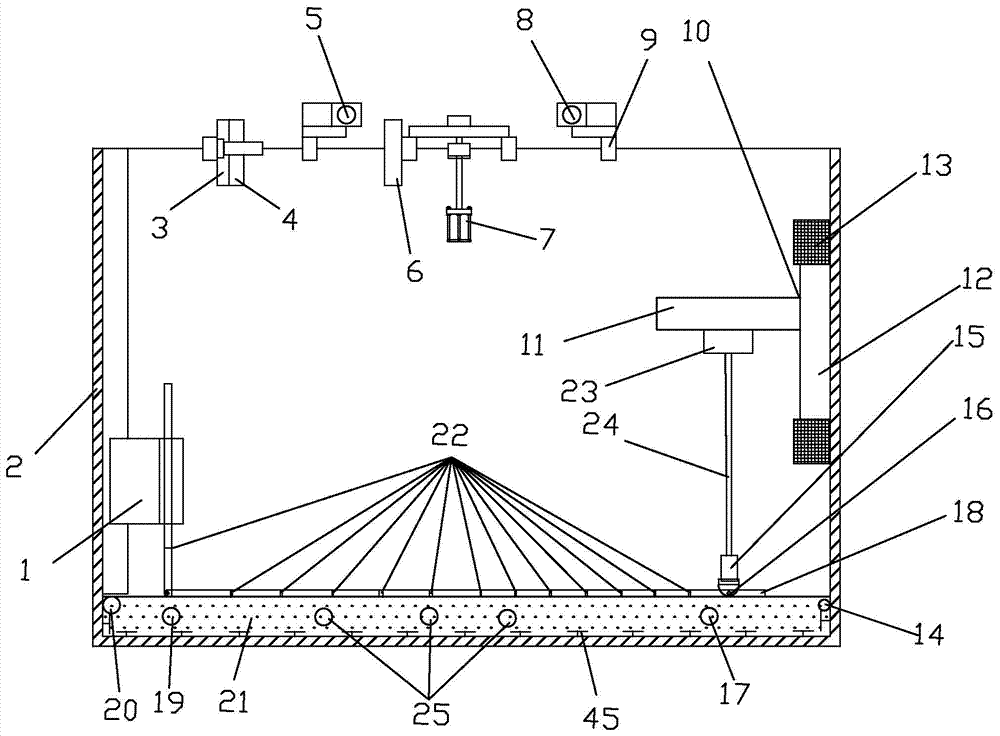

[0027] Example 1: An experimental setup for the interaction between a three-dimensional steel catenary riser and soil, such as figure 1 , Figure 7 As shown, it includes soil box 2, fixed clip 1, connecting rod 24, universal rotating shaft 15, three-dimensional moving mechanism 10, data acquisition unit, computer 37 and servo motor 39, wherein, the data acquisition unit includes: laser data collector; The acquisition unit also includes: a strain sensor 36 for measuring the bending moment of the test tube, a soil consolidation LVDT displacement sensor for monitoring the soil consolidation, a test tube positive settlement LVDT displacement sensor for monitoring the positive settlement of the test tube, and a sensor for monitoring the lateral settlement of the test tube. Test tube lateral settlement LVDT displacement sensor, ring soil penetration tester to measure changes in soil strength near the trench and two lasers to monitor trench dimensions during test tube movement; data ...

example 2

[0040] Example 2: Figure 8 As shown, example 2 is to change the cavity of the soil box in example 1 into upper and lower sections, and other structures are the same as example 1. Specifically, the cavity of the soil box comprises an upper segment cavity 43 and a lower segment cavity 44, the lower segment cavity is a cube-shaped cavity, the upper segment cavity is a cylindrical cavity, and the side length of the lower segment cavity is greater than the diameter of the upper segment cavity, The bottom end of the fixing clip is at the junction of the upper inner cavity and the lower inner cavity, and the claws are covered on the inner wall of the entire lower inner cavity. A motor is installed on the upper inner cavity, and a propeller is installed on the motor shaft, which is driven by the motor. The propeller rotates, and the propeller drives the water in the upper cavity to rotate or reverse, so that the water in the soil box can truly simulate the movement state of seawater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com