Half-breadth metallization safety film

A safety film and metallization technology, applied in the field of capacitors, can solve the problems that the characteristics of the two-layer metallized film cannot be completely consistent, the performance of capacitors is unstable, and the service life is affected, so as to achieve good popularization and application value, good process quality effect, and improved performance. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

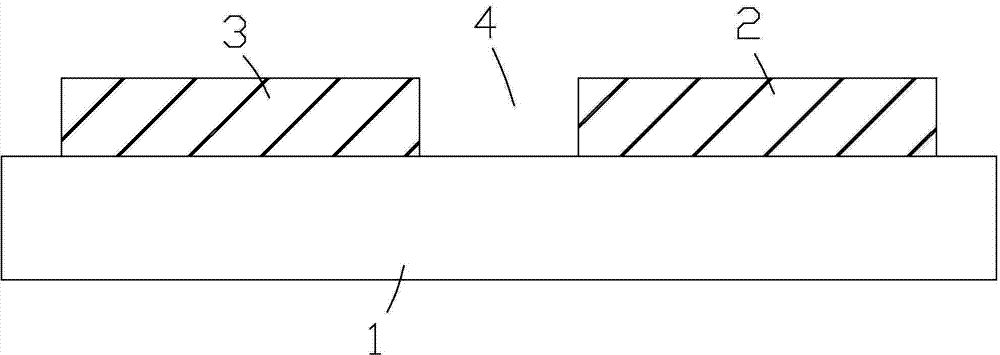

[0012] Such as figure 1 As shown, a half-width metallized safety film includes a base film 1. When the base film 1 is vapor-deposited, oil shielding technology or belt shielding technology is used on half of the base film 1 to make a plurality of disconnected small The pattern area cannot be plated with metal, thus forming a plurality of micro fuses, forming a metallized safety film 2, while the other half of the format is not shielded, forming a whole metallized area, forming a common metallized film 3, after the vapor deposition is completed By cutting, the paired metallized safety film 2 and the common metallized film 3 with completely consistent performance can be obtained. The metallized safety film capacitor made of the paired film has goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com