Quality evaluation method of target assembly used in forming thin film for semiconductor layers of thin film transistor

A thin-film transistor and quality evaluation technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, and material analysis using microwave means, can solve problems such as productivity and cost reduction, and achieve improved yield and shortened Period, the effect of productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0040] (first process)

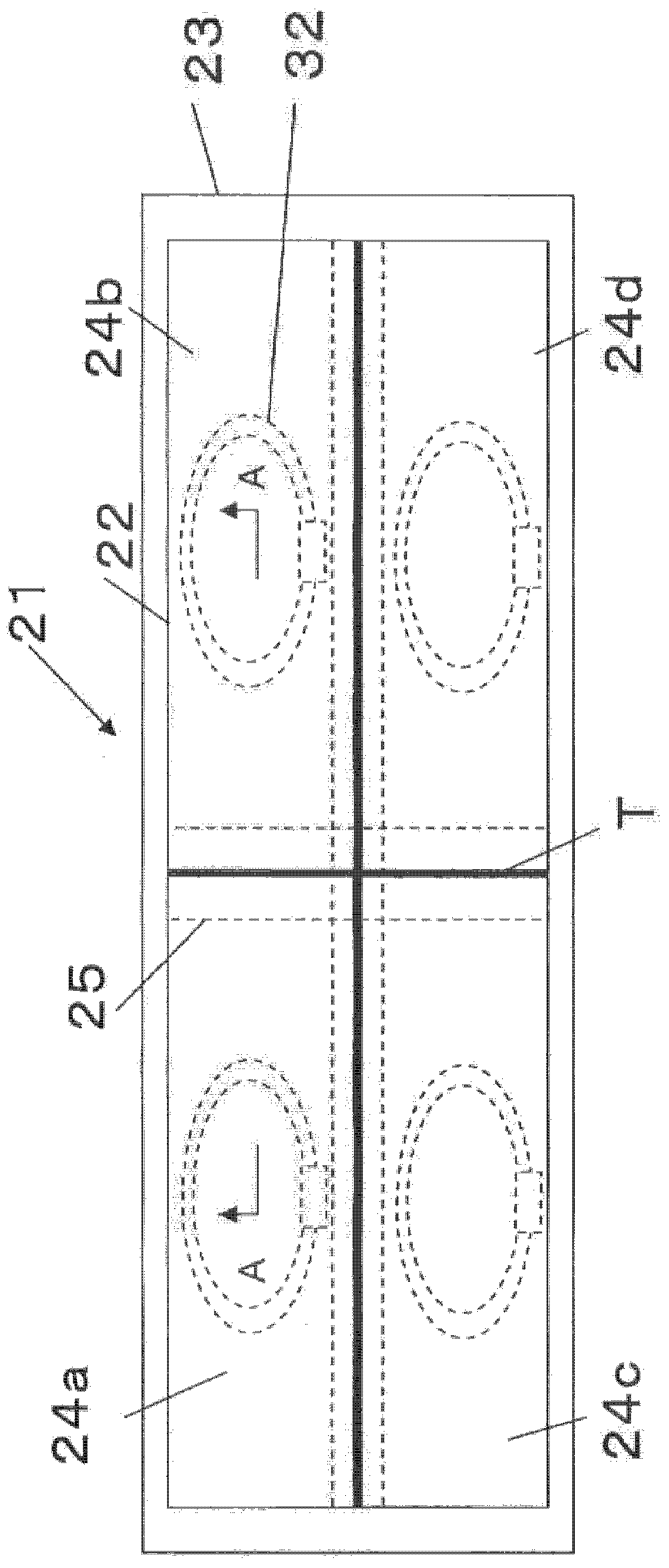

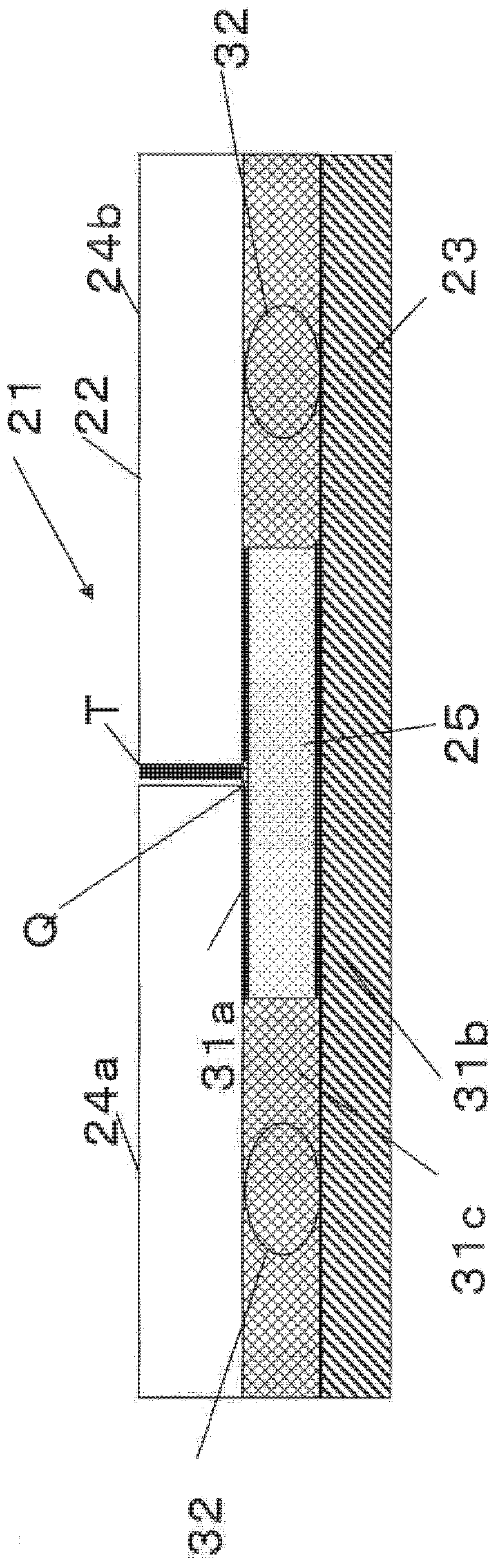

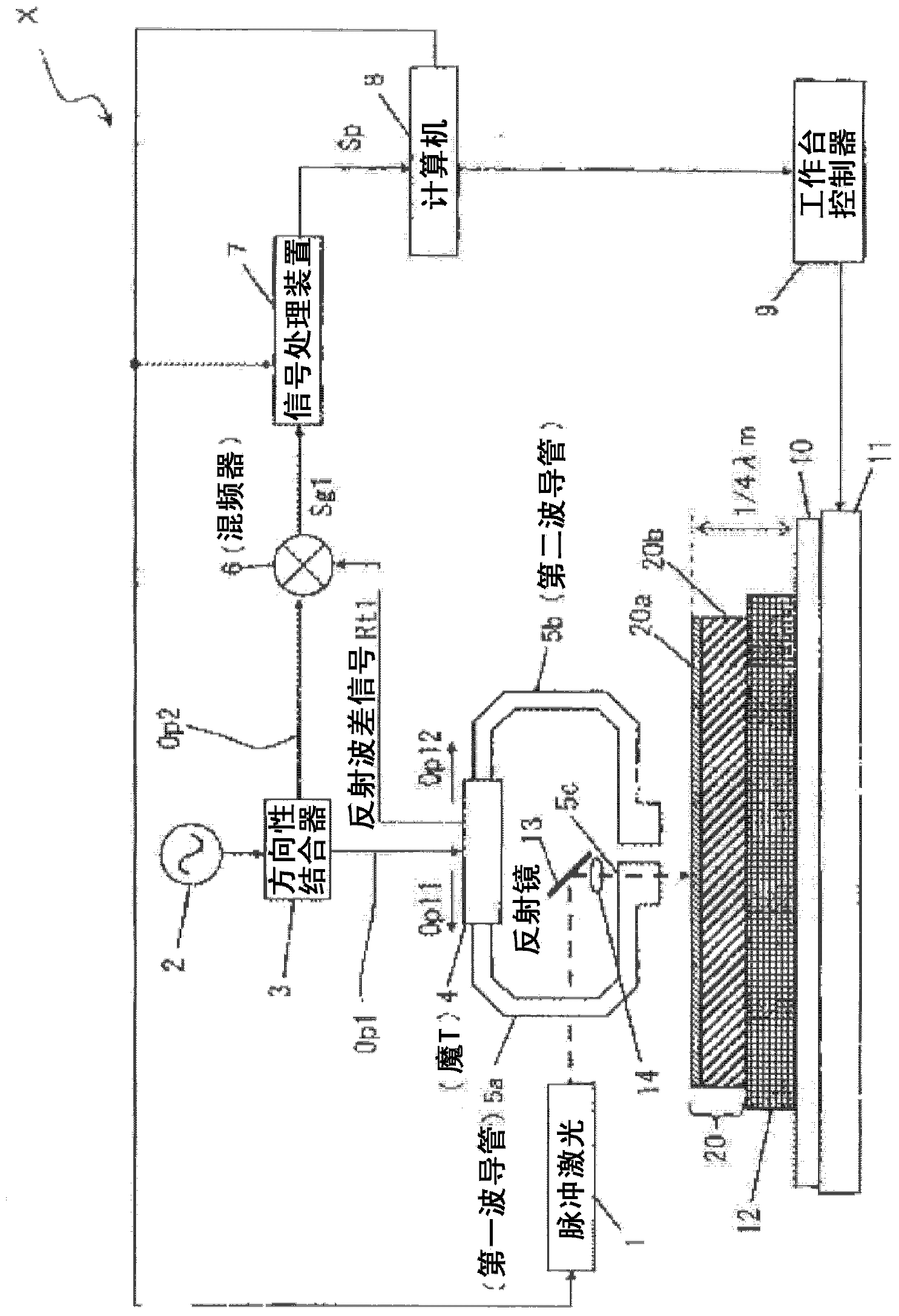

[0041] First, if figure 1 and figure 2 As shown, a target assembly 21 is prepared in which a plurality of oxide target members 24 a to 24 d are arranged on a back plate 23 with gaps T provided via bonding materials 31 a to 31 c. figure 1 and figure 2 The shown target assembly 21 includes: a sputtering target 22 formed by arranging four target members 24 a to 24 d in front, back, left, and right sides, a back plate 23 for fixing (supporting) the sputtering target 22 , and multiple The target members 24a to 24d are bonded with low-melting point solder 31a to 31c to join the back plate 3 . The lining member 25 is provided so that the gap T may be closed on the back side (low-melting-point solder bond material 31a side) of the gap T of several adjacent target members 24a-24d. The spacers 32 (Cu wires) are arranged between the target members 24 a to 24 d and the back plate 23 so that a uniform gap can be formed.

[0042] Examples of the target member...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com