An external cooling system with cold storage for DC converter valve and its operation method

A DC converter valve and external cooling technology, applied in cooling/ventilation/heating transformation, output power conversion devices, electrical components, etc., can solve problems such as short transition time, short accumulation time, and large climate sensitivity, and achieve Improved reliability, strong water-saving and environmental protection performance, and improved redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

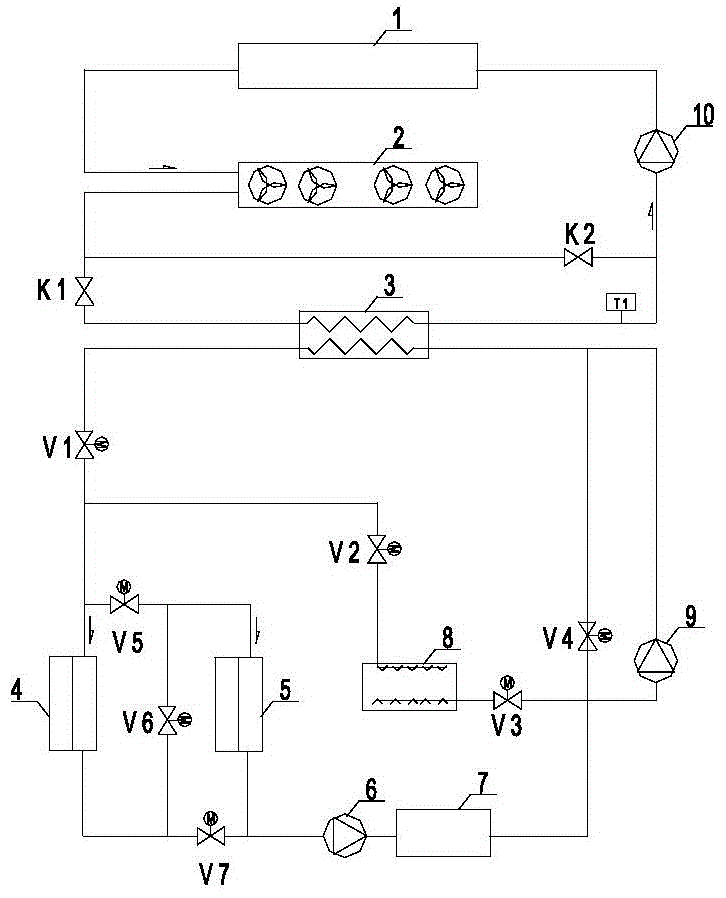

Embodiment 1

[0046] When the ambient temperature is lower than 5°C, 1 / 2 of the flow of cooling water on the hot side of the plate heat exchanger 3 bypasses the valve K2, and 1 / 2 of the flow flows into the plate heat exchanger 3 and exchanges heat with the plate heat exchanger. The chilled water on the cold side of the device 3 performs heat exchange, the first chiller 4 and the second chiller 5 are turned off, and the fixed-frequency cold pump 6 and the variable-frequency cold pump 9 are turned on, so that the heated chilled water goes to the thermocline type cold storage tank 8 Heat storage.

Embodiment 2

[0048] When the ambient temperature is 5° C. to 35° C., the entire flow of cooling water on the hot side of the plate heat exchanger 3 bypasses the valve K2 to reduce the pressure loss of the cooling water pump 10 .

Embodiment 3

[0050] When the ambient temperature is higher than 35°C, 2 / 3 of the flow of cooling water on the hot side of the plate heat exchanger 3 bypasses the valve K2, and 1 / 3 of the flow flows into the plate heat exchanger 3 and exchanges heat with the plate heat exchanger. The chilled water on the cold side of the device 3 performs heat exchange, and the chilled water is used for cooling to cool down the cooling water.

[0051] Divided into the following four operating modes:

[0052] Cooling storage mode at night: valve V1, valve V4, valve V5, valve V7 and variable frequency cold pump 9 are closed, valve V6, first chiller 4, second chiller 5 and fixed frequency cold pump 6 are turned on, when the inclined temperature layer cold storage When the water temperature in the tank 8 reaches 4°C, the cold storage is completed.

[0053] Chiller cooling mode alone; valve V2, valve V3, valve V6 and variable frequency cooling pump 9 are closed, valve V1, valve V4, valve V5, valve V7, first chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com