Extrusion device for pelletizer

A technology of extrusion device and granulator, which is applied in the field of granule forming equipment, can solve the problems of looseness, high energy consumption of granulator, and many granule cracks, etc., and achieve the effect of low processing cost, high production efficiency and compact compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

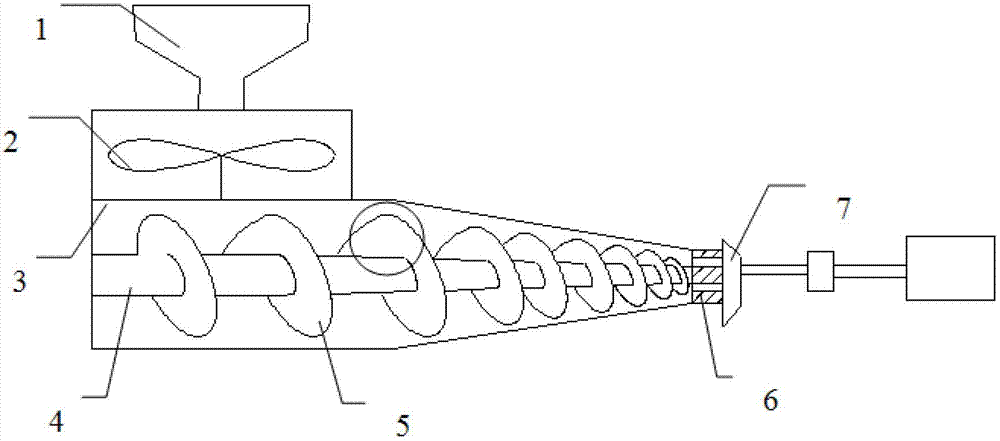

[0015] Such as figure 1 As shown, the present invention creates a kind of granulator extruding device, comprises extruding cylinder 3, screw extruder and discharge port 6, and described extruder is surrounded by extruding shaft 4 and described extruding The extruding vane 5 on the shaft is composed of the extruding vane 5 gradually decreasing from the inlet 1 to the outlet 6; the adjacent extruding vanes 5 are from the inlet 1 to the outlet 6 The direction spacing gradually decreases; the cross section of the extruding cylinder 3 gradually decreases from the feed port 1 to the discharge port 6 . Such a tapered shape gradually reduces the space of the molding raw material in the extrusion device, and the raw material is further compressed, and the air will be gradually squeezed out from the gap between the raw materials to form molding particles with uniform density and tight texture.

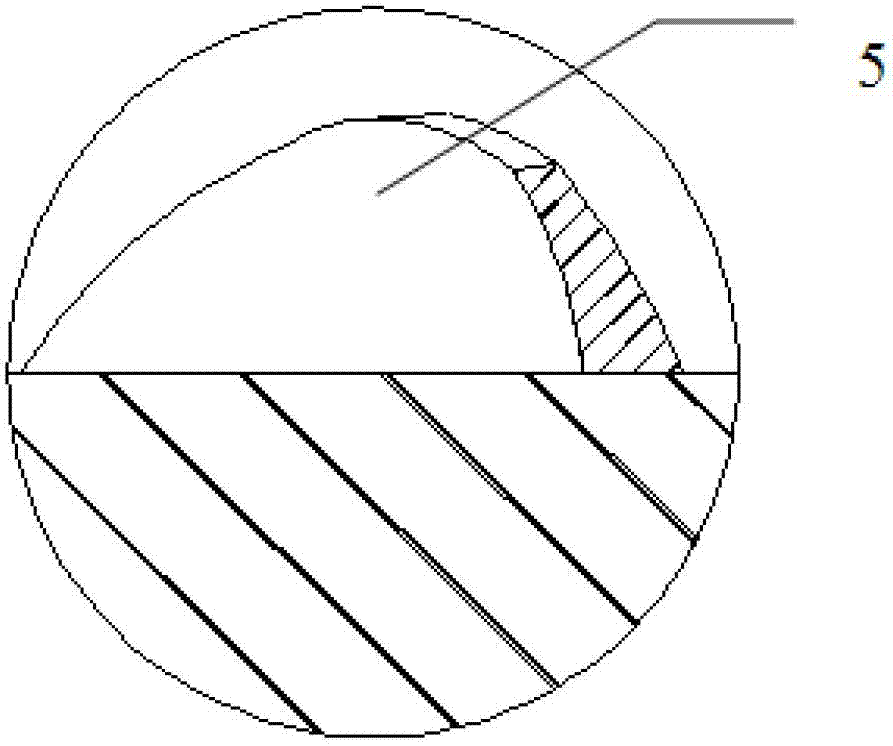

[0016] Such as figure 2 As shown, the cross-section of the extruding blade 5 is wide near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com