Device for peeling outer circle of copper rod

A technology for stripping outer circles and copper rods is applied in the field of outer circle stripping devices, which can solve problems such as low machining accuracy of outer surfaces, and achieve the effects of reducing labor intensity and product cost, improving work efficiency and solving efficiency problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

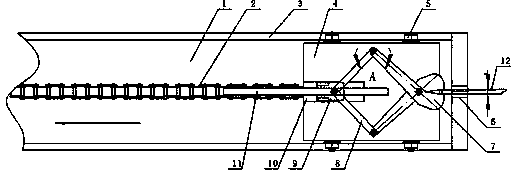

[0012] Depend on figure 1 , figure 2 As we know, the copper rod peeling outer circle device consists of main bracket 1, chain 2, track 3, trolley 4, roller 5, cutter head 6, chuck 7, connecting rod 8, slider 9, slideway 10, hook 11, copper rod 12 compositions. Collet 7 is installed on the dolly 4 with bolts, and one end of connecting rod 8 is connected with collet 7 with bolts, and the other end is connected with slide block 9, and slide block 9 is placed in slideway 10 li. Hook 11 is connected together with slide block 9 with column pin. The roller 5 on the dolly 4 is placed on the track 3 of the main support 1 . The plane of the track 3 forms a certain angle with the horizontal plane. When the outer circle of the copper rod is peeled off, the hook 11 leaves the chain 2 due to gravity, and the dolly 4 automatically returns to the position of the cutter head 6.

[0013] Copper rod 12 passes the cutter head hole of cutter head 6 and is placed in collet 7 li. Pull the hook...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com