Automatic positioning and screwing mechanism of main and auxiliary seat frames and control method thereof

A technology of automatic positioning and main seat frame, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of labor cost, process, quality, efficiency, and working hours are not as good as automation equipment, and the demand for manpower is large, so as to achieve convenience Automated control and management, improved production efficiency, and accurate positioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the drawings and embodiments:

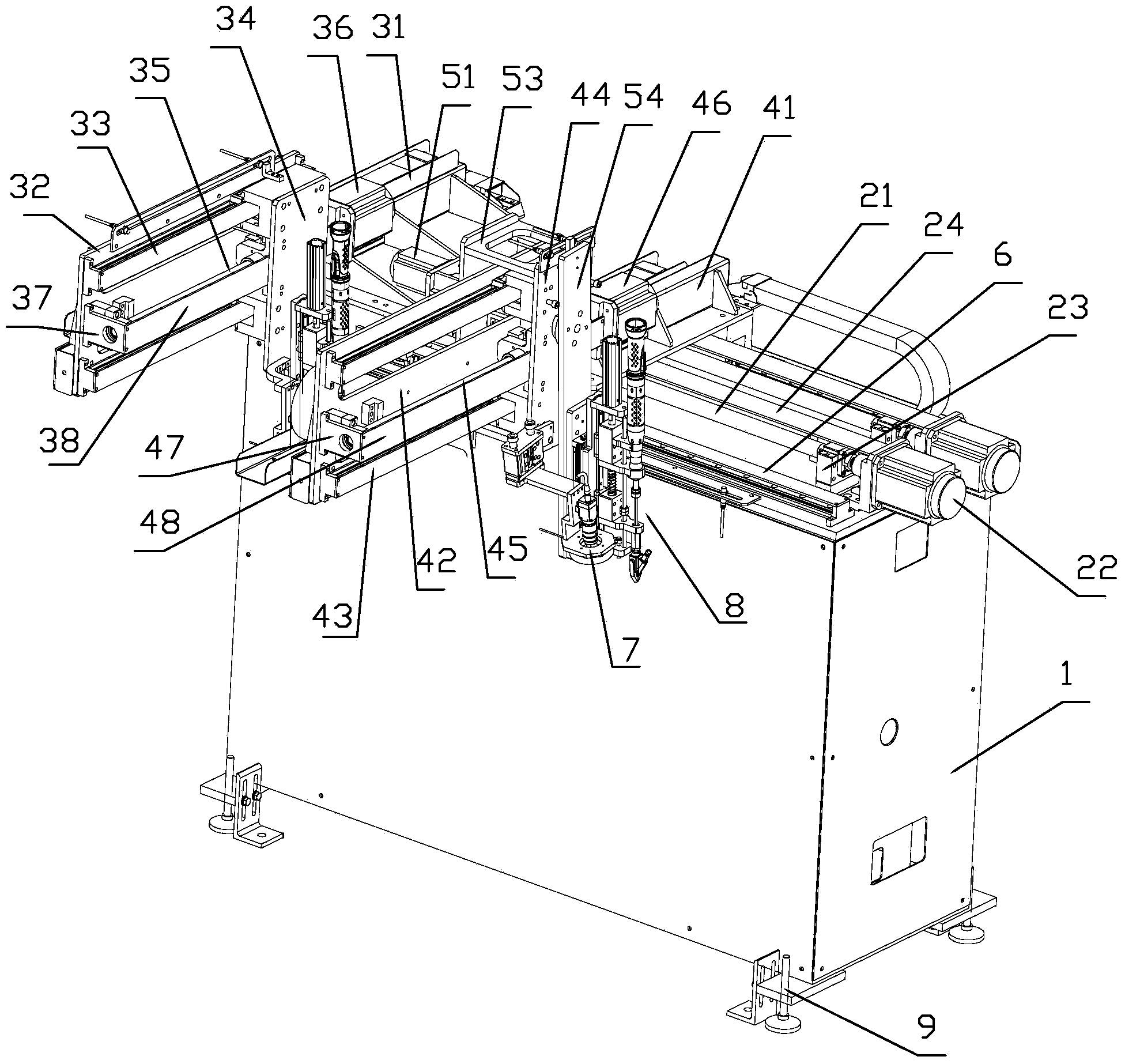

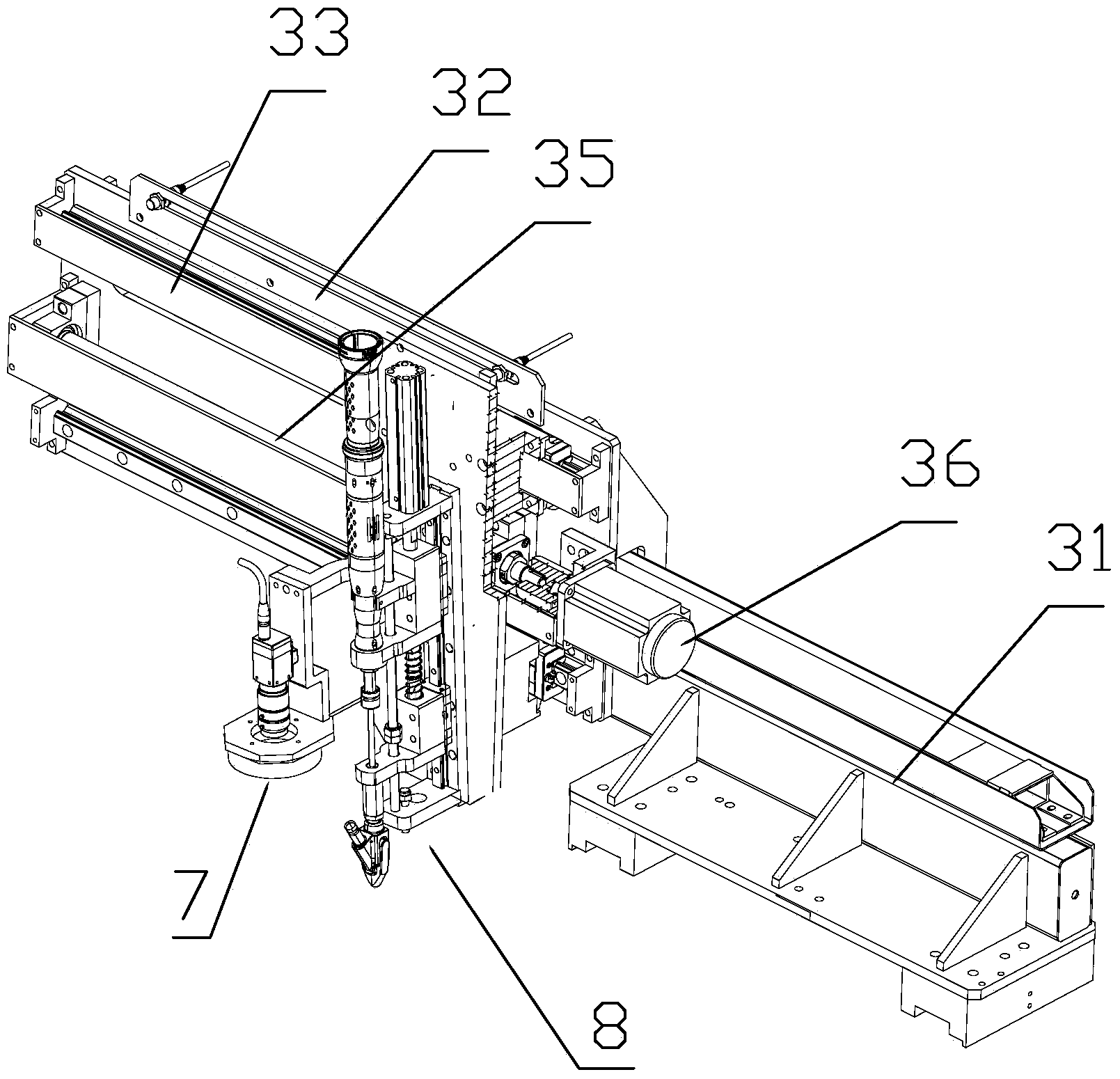

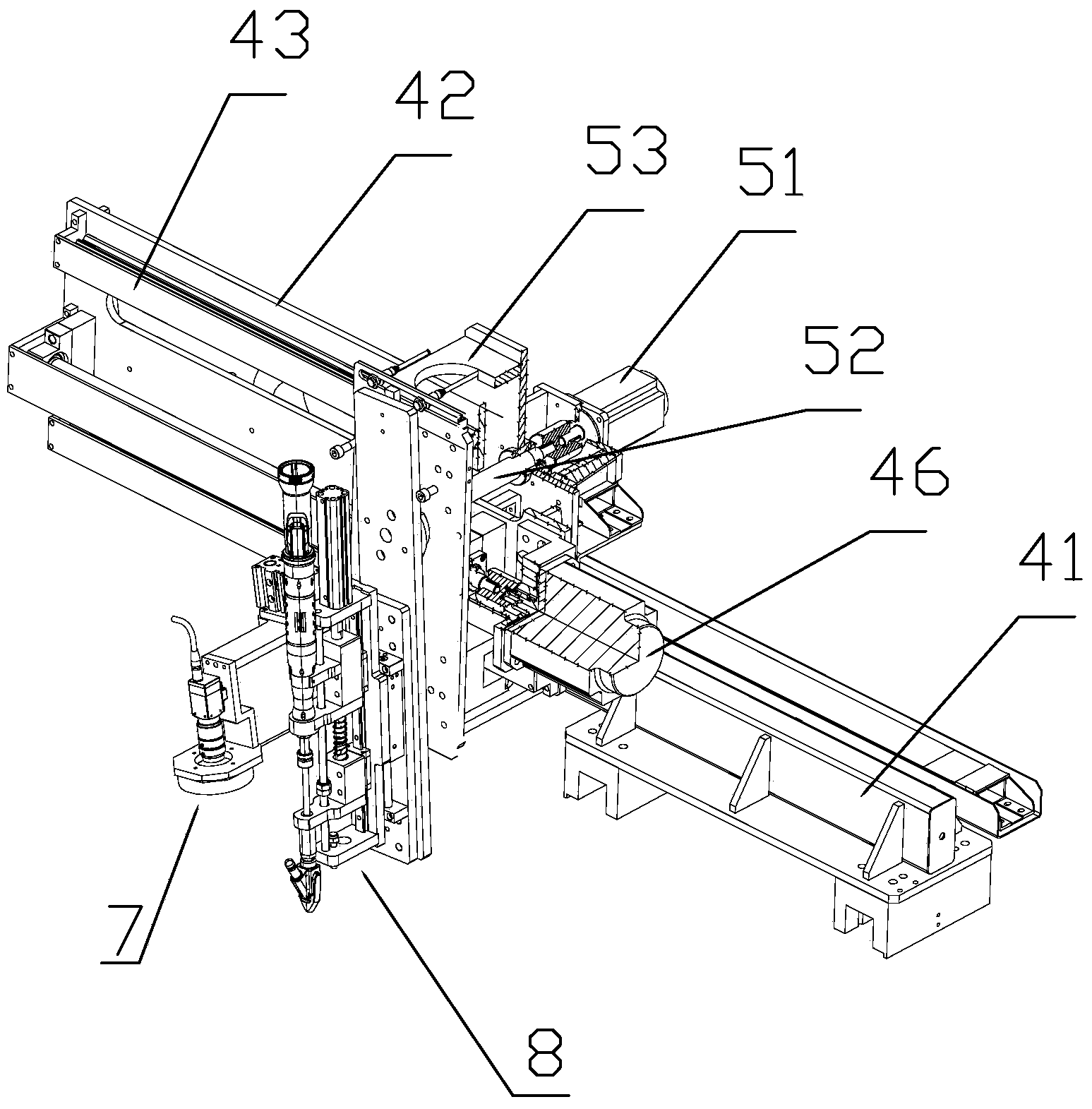

[0035] Such as Figure 1 to Figure 3 As shown, an automatic positioning and tightening mechanism for the main and sub-seat frames includes a base 1 with a rectangular parallelepiped structure. The base 1 is mounted on a cup-shaped bracket 9. The base 1 is horizontally provided with two first guide rails 6, two A first lead screw 21 and two first servo motors 22. The front ends of the two first lead screws 21 are respectively connected to two first servo motors 22. The first lead screws 21 and the first servo motors 22 are located in the two first servo motors. Between the guide rails 6, a secondary support seat 41 and a main support seat 31 are installed on the first guide rail 6 along the front-rear direction. The lower part of the main support seat 31 is fitted on one of the first screws 21, and the lower part of the secondary support seat 41 is fitted on the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com