Biomaterial three-dimensional forming equipment and its extrusion nozzle

A biomaterial and three-dimensional forming technology, which is applied in the fields of biomanufacturing and biomaterial three-dimensional printing, can solve the problems of small material temperature control range, limited material viscosity adjustment range, and unsatisfactory forming effect, so as to achieve temperature control and precise temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

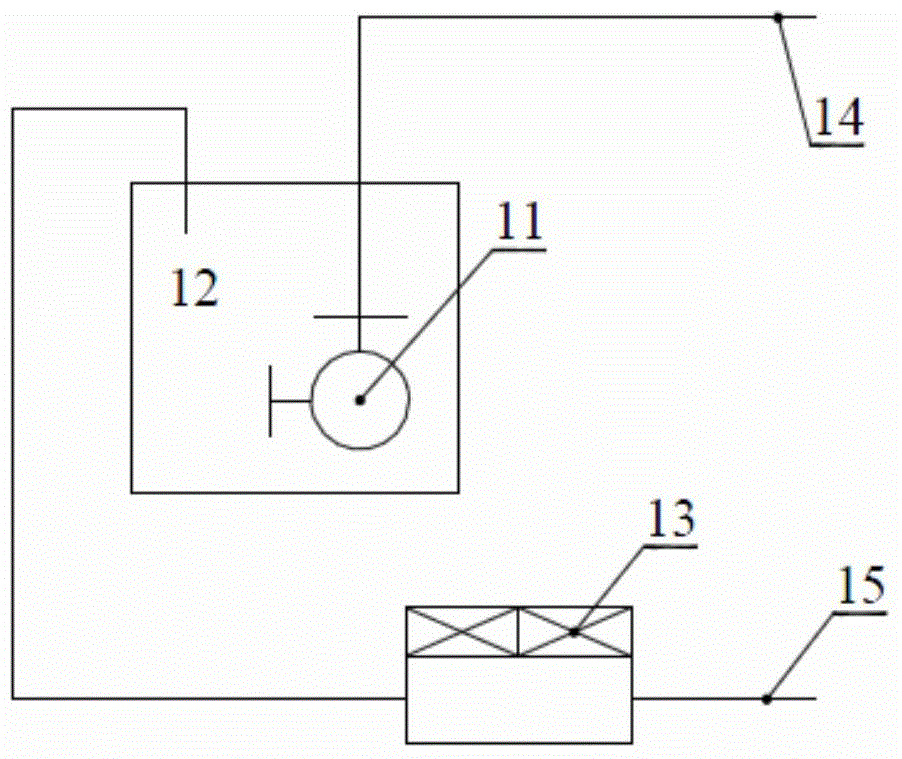

[0022] This embodiment provides a three-dimensional biomaterial molding device, which includes an extrusion nozzle in the form of a syringe, and the nozzle is provided with an extrusion driving unit and a pre-extrusion temperature control unit.

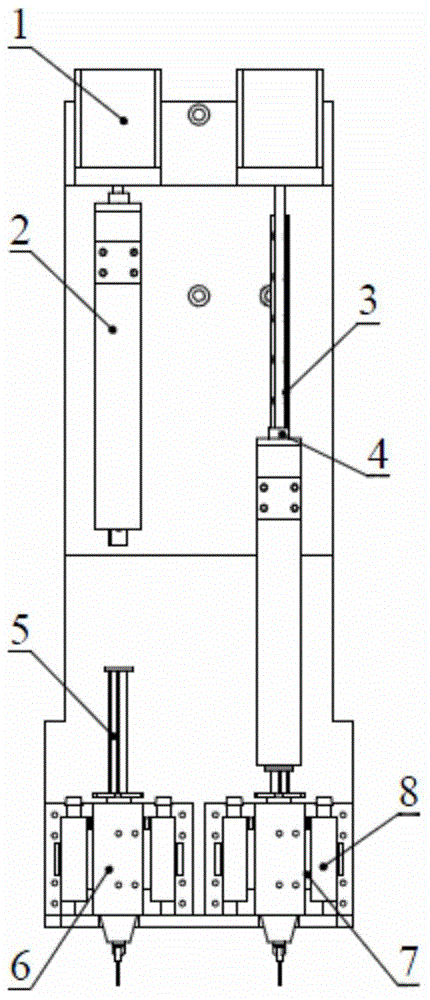

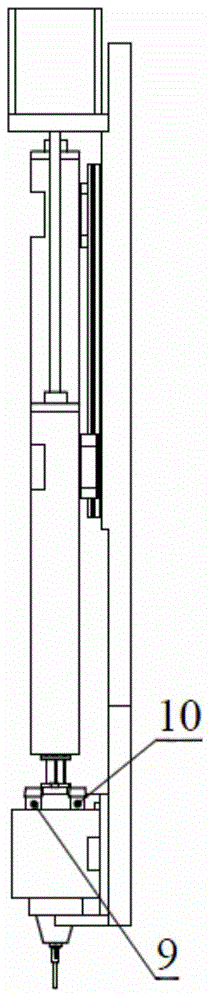

[0023] Such as figure 1 , 2 As shown, the extrusion drive unit of this embodiment includes multiple sets arranged side by side, and each extrusion drive unit can be equipped with a medical sterile syringe containing biomaterials, and the extrusion drive unit pushes the piston of the syringe to extrude The syringe holds the biomaterial for printing. The extrusion driving unit of this embodiment includes a drive motor 1, a syringe push rod 2, a linear guide rail 3 and a slider 4; The guide rail 3 moves down; the drive motor 1 is used to push the syringe push rod 2. see figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com