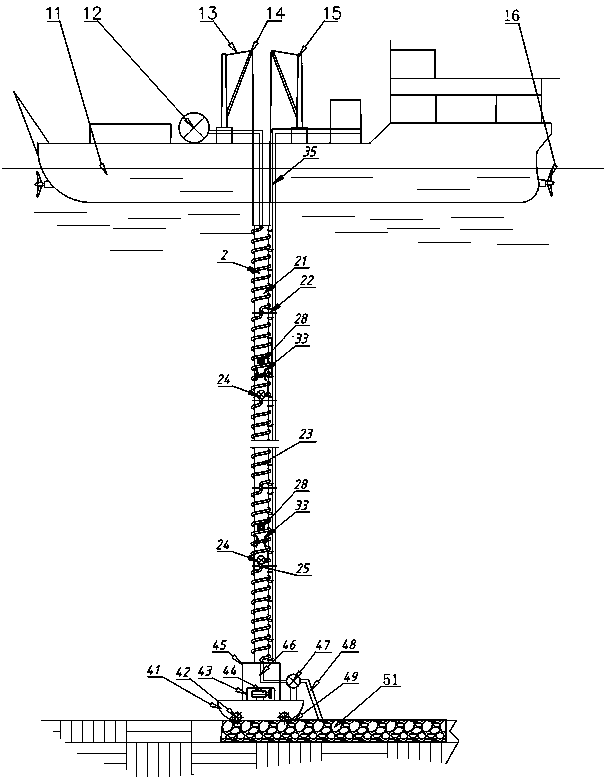

Deepwater mining annular pipeline lifting and conveying device

A ring-shaped pipeline and conveying device technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of sinking to the bottom in the rigid lifting pipe, the proportion of minerals is large, and the conveying efficiency is low. Weight, improve conveying efficiency, and solve the effect of international technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

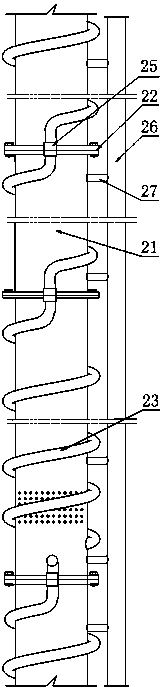

[0014] The length of the total support pipe 2 is according to the design requirements, and is formed by fixing more than one section of support pipe 21 through the connector support pipe flange 22, such as figure 1 shown.

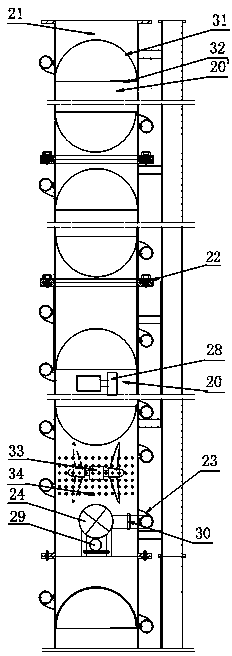

[0015] In the inner cavity of every section support tube 21, there are buoyancy air chambers 20, 20' formed by upper and lower semicircular cover plates 31 and baffle plates 32 and the inner walls of part support tube 21. Only the length is different, and the buoyancy air The cabin 20' length is greater than the buoyancy air cabin 20, can reduce the weight of the whole device, as image 3 shown.

[0016] According to the needs of the site situation, more than two buoyancy air chambers 20' are installed in a section of support pipe every 100-1000 meters, and the first electric hydraulic pump is installed in the buoyancy air chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com