Lubricating material for cold rolling and its preparation method and use

A technology of lubricating materials and lubricants, applied in the direction of lubricating compositions, petroleum industry, etc., can solve the problems of poor annealing cleanliness and environmental protection performance of finished products, fast replacement cycle of rolling mill bearings, environmental and human injury, etc., and achieve good annealing cleanliness , Avoiding stress corrosion problems, reducing the time to replace rolls and bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation of lubricating material for cold rolling

[0041] A lubricating material for cold rolling, comprising the following raw materials in percentage by weight: paraffin base oil 20%, 2,6-di-tert-butyl p-cresol 0.3%, pentaerythritol oleate 30%, trimethylolpropane oleic acid 30% ester, 1% tricresyl phosphate, 2% sulfurized vegetable oil fatty acid, 1% modified fatty acid monoethanolamine amide, 2% sulfurized calcium alkylphenate, 1.5% triethanolamine, 4% sorbic anhydride monooleate, fatty alcohol Polyoxyethylene ether 1.5%, castor oil polyoxyethylene fatty acid ester 1.5%, alkylated polyvinyl pyrrolidone 0.5%, ricinoleic acid 4.7%.

[0042] Preparation:

[0043]First add paraffin base oil, modified fatty acid monoethanolamine amide, pentaerythritol oleate and trimethylolpropane oleate into the reaction kettle, stir evenly, then add tricresyl phosphate, sulfurized vegetable oil fatty acid, triethanolamine in sequence , sorbic anhydride monooleate...

Embodiment 2

[0046] Embodiment 2: the preparation of lubricating material for cold rolling

[0047] A lubricating material for cold rolling of a 650mm four-high four-rolling mill, including the following raw materials in weight percentages: 20% paraffinic base oil, 10% naphthenic base oil, 0.2% diphenylamine, 2,6-di-tert-butyl 0.3% p-cresol, 30% animal oil, 10% palmitate, 10% trimethylolpropane oleate, 0.5% ammonia neutralized modified phosphate, 4.5% sulfurized olefin, 1 dodecenyl succinic acid %, calcium salicylate 1%, triethanolamine 3%, castor oil polyoxyethylene fatty acid ester 2%, ethoxylated castor oil 1.5%, tall oil 1.7%, palmitoleic acid 4%, isomer hard Fatty acid 0.3%.

[0048] Preparation:

[0049] First add paraffinic base oil, naphthenic base oil, dodecenyl succinic acid, animal oil, palmitate, trimethylolpropane oleate into the reaction kettle, stir evenly, and then add ammonia to neutralize Modified phosphate ester, sulfurized olefin, tall oil acid, palmitoleic acid, iso...

Embodiment 3

[0052] Embodiment 3: the preparation of lubricating material for cold rolling

[0053] A lubricating material for cold rolling of a 650mm four-high four-rolling mill, including the following raw materials in weight percentage: 35% of naphthenic base oil, 0.5% of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide %, vegetable oil 20%, glyceryl trioleate 8%, pentaerythritol oleate 13.5%, tricresyl phosphate 0.5%, sulfurized lard 3%, sulfurized vegetable oil fatty acid 2%, sodium petroleum sulfonate 4%, succinic acid derivative 1%, succinate polymer 1.5%, fatty acid amine 2.5%, sorbic anhydride monooleate 3%, oleyl alcohol polyoxyethylene ether 1.5%, tall oleic acid 4%.

[0054] Preparation:

[0055] Add naphthenic base oil, sodium petroleum sulfonate, succinic acid derivatives, vegetable oil, glyceryl trioleate, pentaerythritol oleate into the reaction kettle, stir evenly, then add tricresyl phosphate, vulcanized lard in sequence , sulfurized vegetable oil fatty acid, fatty acid ...

PUM

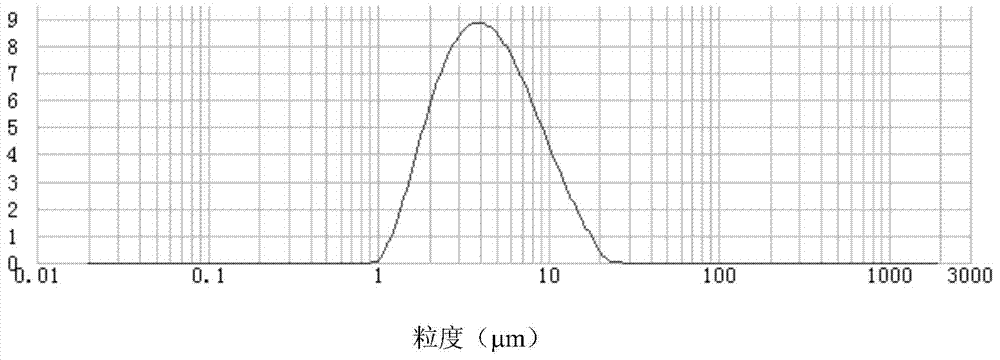

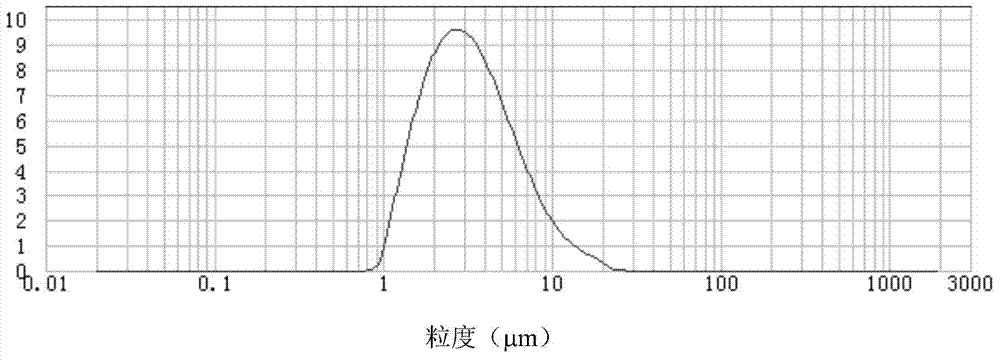

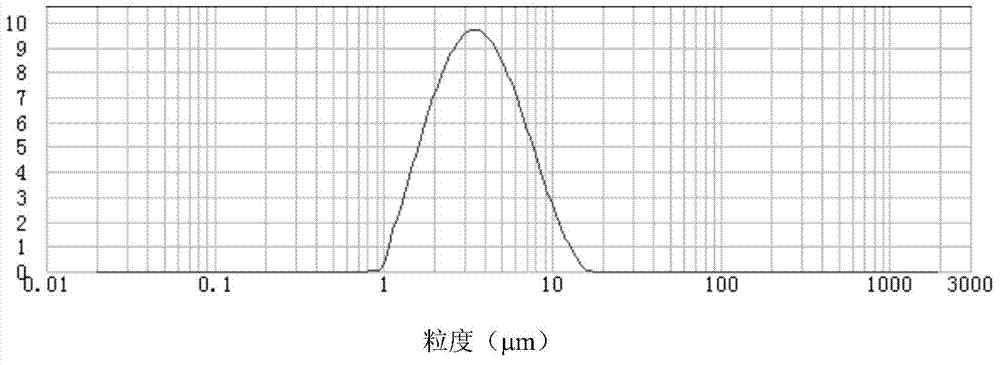

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com