A ductile iron casting process

A casting process and ductile iron technology, applied in the field of ductile iron casting process, can solve the problems of polluted operating environment, low absorption rate of nodularizing agent, large amount of nodularizing agent used, etc. and smoke removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with examples.

[0035] The ductile iron that model is QT500-7 is manufactured by this process now, and this manufacturing process comprises the following steps:

[0036] (1) Spheroidization package preparation:

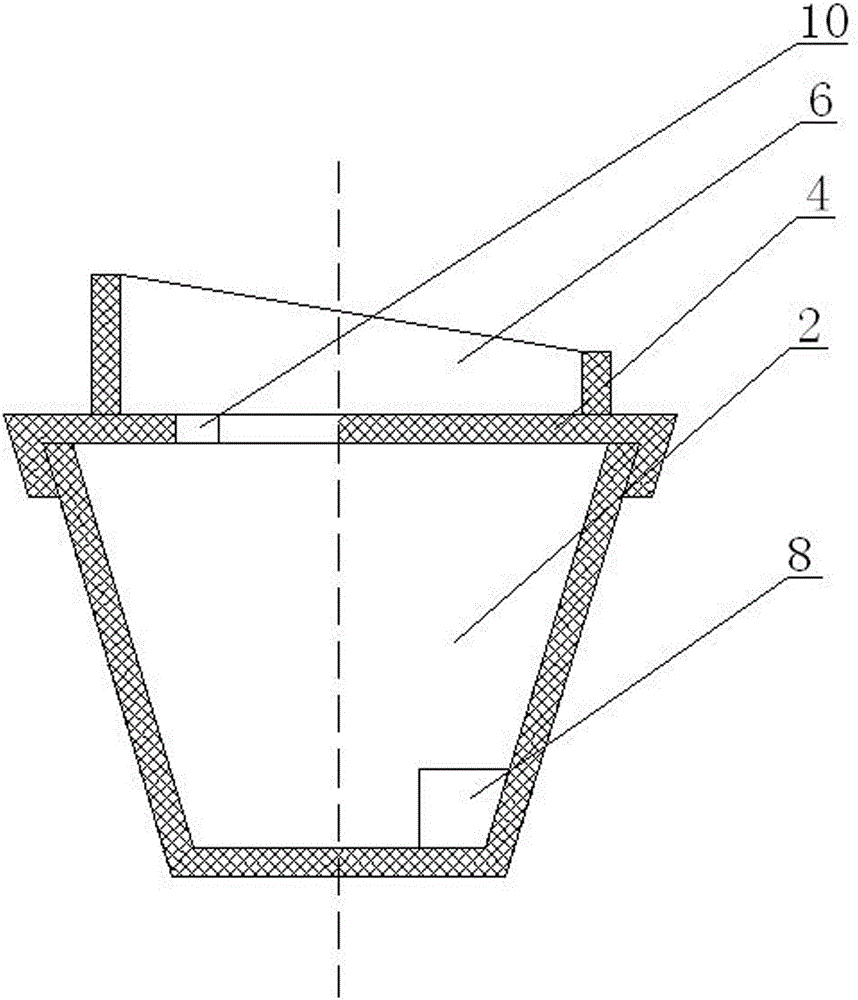

[0037] a. If figure 1 As shown, the spheroidizing bag includes a spheroidizing bag body 2 for placing molten iron, and a bag cover 4 arranged above the bag body 2. The bag cover 4 is provided with a groove cavity 6, and one end of the bag body 2 bottom is provided with a In the pit 8 of the spheroidization reaction, the other end of the cover 4 located at the pit 8 is provided with a casting liquid inlet 10, which is respectively connected with the cavity mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com