Settlement joint treatment structure

A technology of settlement joints and side joints, which is applied in the direction of building structure, floors, buildings, etc., can solve the problems of high cost of finished settlement joints, long construction period, and difficult on-site operation, so as to reduce labor costs and technical requirements, and meet On-site installation needs, the effect of saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

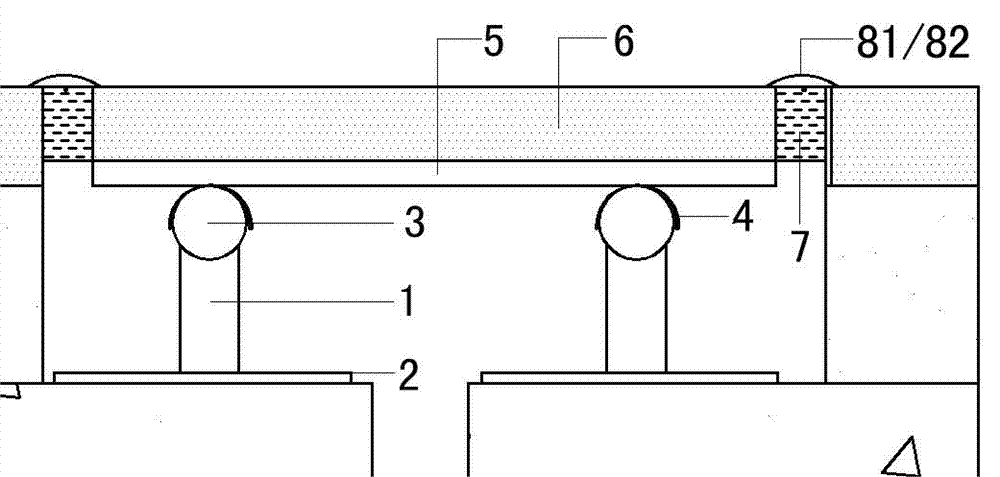

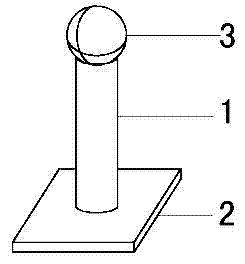

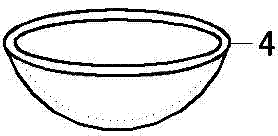

[0020] Embodiment one: if figure 1 As shown, a settlement joint treatment structure includes threaded support rod 1, base 2, steel ball 3, hemispherical device 4 matched with steel ball, bottom plate 5, stone material 6, side seam 7, profile closing strip 81.

[0021] Such as figure 2 As shown, the threaded support rod 1 with a suitable height is customized according to the site conditions. The threaded support rod 1 is a solid screw rod with full teeth. The threaded support rod 1 is fixed on the concrete layer with expansion bolts to ensure the stability of the threaded support rod 1. The steel ball 3 is screwed into the threaded support rod 1 through the internal thread, and the height can be adjusted through the adjustment of the thread, which is convenient for the leveling of the device; the threaded support rod 1 and the base 2 are combined and fixed on the concrete floor, and the steel ball 3 is connected to the The threaded support rod 1 is connected as a height-adjus...

Embodiment 2

[0023] Embodiment 2: The difference from Embodiment 1 is that the edge seam 7 is closed by a stainless steel closing strip 82 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com