Wood veneer clip installation structure

A technology for installing structures and wood veneers, which is applied in building construction, covering/lining, construction, etc., can solve problems such as the inability to control the overall level of the wood veneer surface, difficulty in later maintenance, and more time and money. Achieve the effect of facilitating productized installation operations, reducing material costs, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Example: such as Figure 7 Shown: a wooden veneer clip installation structure, which includes a clip 2, a bolt base 4, and a steel sheet 3.

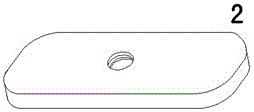

[0021] Such as Figure 5 As shown, there is a screw hole 1 in the middle of the clamping piece 2, and the clamping piece 2 is rotatably connected with the bolt base 4 through the screw hole 1; On steel sheet 3.

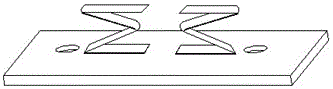

[0022] Such as image 3 As shown, the steel sheet 3 is welded with a spring sheet, and the spring sheet is arranged between the steel sheet 3 and the bolt base 4 . The spring leaf is provided with two pieces.

[0023] Such as figure 2 As shown, the clip 2 is square with rounded corners. The clamping piece 2 is fixed on the rectangular perforated steel piece 3 with two spring pieces by combining with the bolt base 4, and the assembled clamping piece is fixed on the wooden keel base layer 6 by self-tapping screws 1 to realize the clamping piece 2. Rotate and fix the cut finished wood veneer 5. The snap-in piece 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com