Large-scale CNC cutting heavy bamboo special-shaped installation structure

An installation structure, large-scale technology, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of instability, easy deformation, large impact, etc., and achieve the effect of short growth cycle, soft color and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

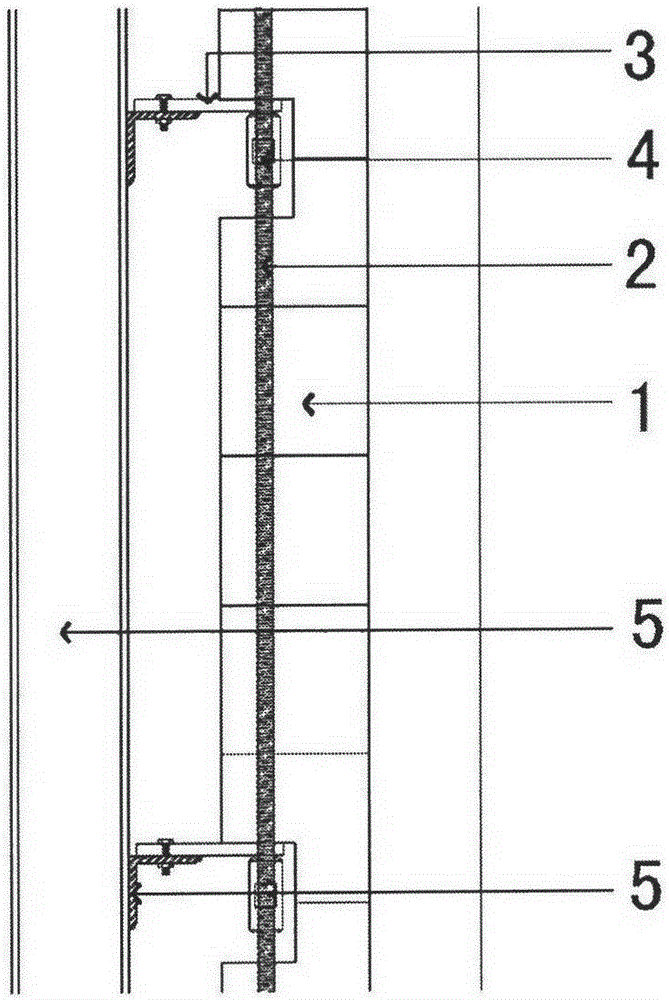

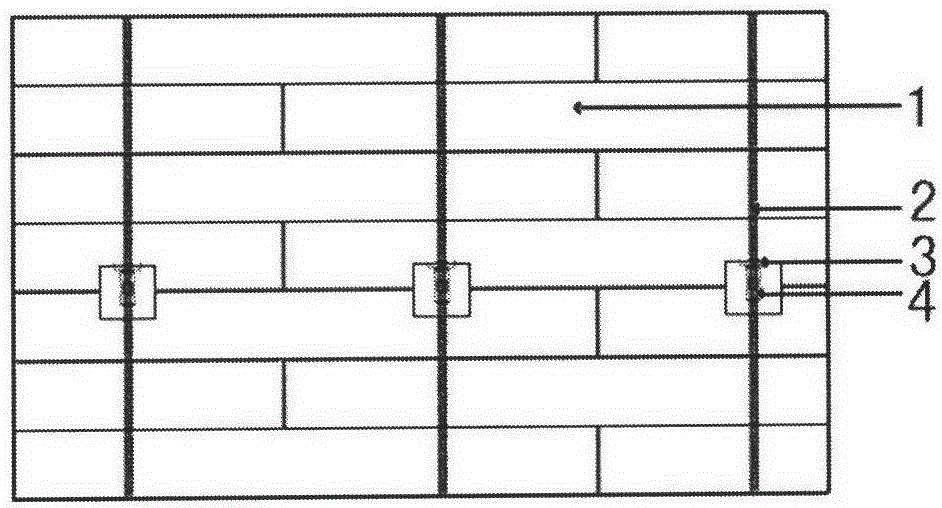

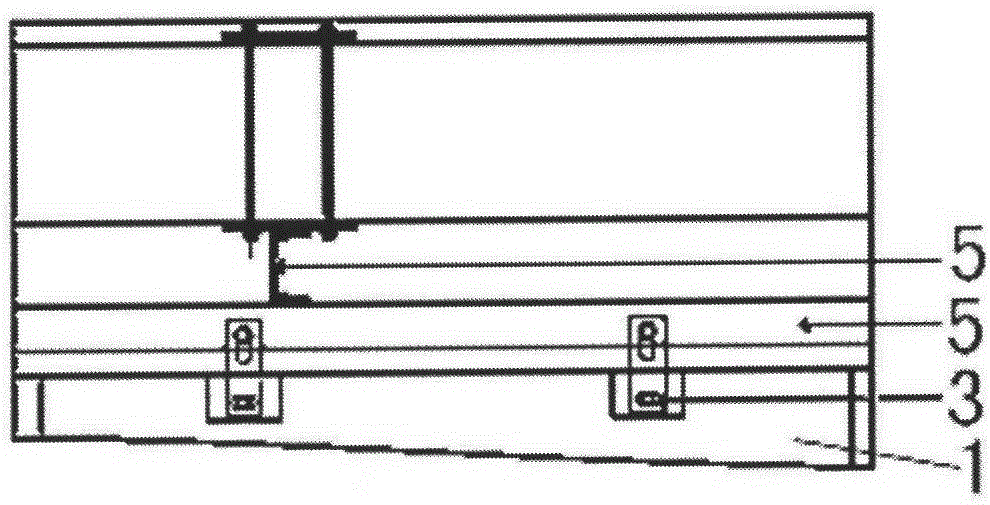

[0022] Example: such as figure 1 , figure 2 , image 3 As shown, a large-scale CNC cutting heavy bamboo special-shaped installation structure, which includes special-shaped CNC cutting heavy bamboo unit 1, screw rod 2, pendant 3, connector 4, steel skeleton base 5. The screw mandrel 2 is a solid screw mandrel with full teeth. The pendant 3 is an adjustable stainless steel pendant with an adjustable connection position.

[0023] The steel skeleton base 5 is composed of a channel steel main keel of 900 mm and an angle steel auxiliary keel of 500 mm. As a design requirement for large-scale special-shaped decorative effects, the shape of each special-shaped CNC-cut heavy bamboo unit 1 is almost completely different, and it is also required that the adjacent special-shaped CNC-cut heavy bamboo units 1 have the same shape and surface to form a perfect arc. The processing difficulty of each piece of special-shaped CNC cutting heavy bamboo unit 1 requires precision. Each piece h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com