lightweight partition

A lightweight, fastener technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of easy dirty, non-reusable, and increased difficulty on the construction site, saving on-site installation time, improving recyclability, The effect of avoiding common quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

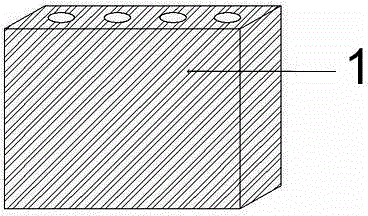

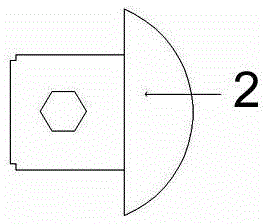

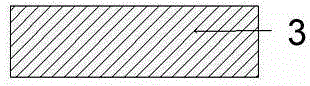

[0035] Example: such as Figure 1 to Figure 10 As shown, a lightweight partition wall includes unit masonry 1, fastener nut 2, fastener bolt 3, combined fastener body 4, and I-shaped metal frame 5, and the combined fastener body 4 is T The combined fastener body 4 is provided with a hole, the fastener nut 2 has its own inner thread, and the fastener nut 2 cooperates with the fastener bolt 3 to fix the combined fastener body 4 on the I-shaped metal frame 5, several spaces that can individually accommodate the unit masonry 1 are formed, and several unit masonry 1 are filled into the space and combined to form a lightweight partition wall.

[0036] The fastener nut 2 cooperates with the fastener bolt 3 and is fixed on the I-shaped metal frame 5 to form a buckle end, and the combined fastener body 4 is fastened to the buckle end through a hole thereon. The unit masonry 1 is a hollow gypsum unit masonry, and sound-absorbing holes are arranged inside the unit masonry 1 . The outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com