Spiral direct-drive electric-hydraulic proportional flow valve with hollow permanent-magnet alternating-current servo motor

An AC servo, electro-hydraulic proportional technology, used in engine components, servo motor components, fluid pressure actuation devices, etc., can solve problems such as increasing equipment costs, immature multi-stage cartridge valve technology, and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

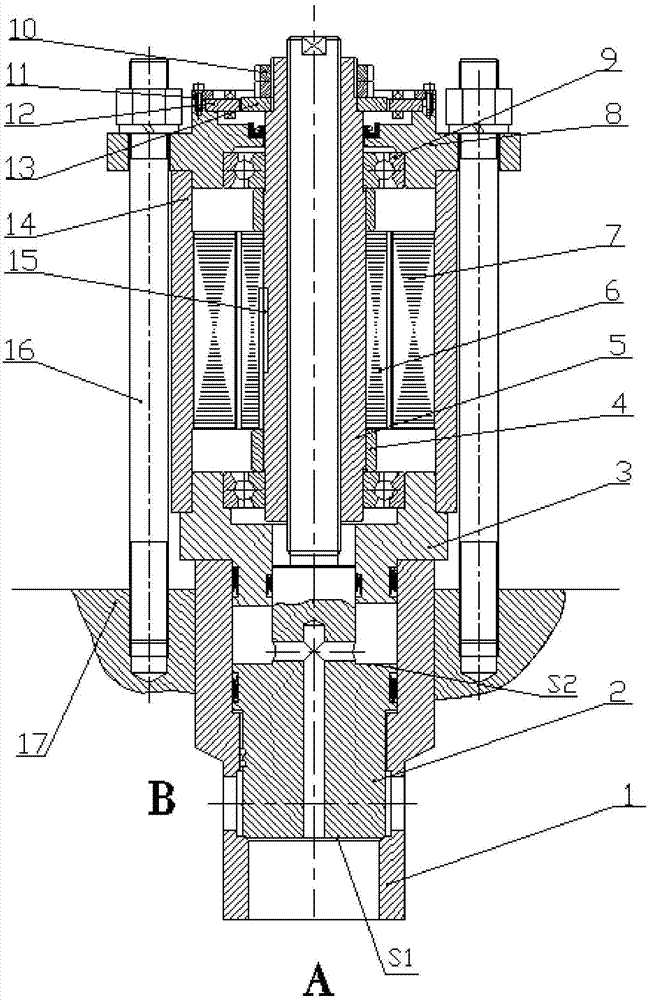

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] As shown in the figure, the hollow permanent magnet AC servo motor helical direct drive electro-hydraulic proportional flow valve includes a valve core 2, which is placed in the valve sleeve 1, and the top of the valve sleeve 1 is connected with a lower cover plate 3, The lower end surface of the lower cover plate 3 forms a cavity with the end surface of the valve core 2, and a central hole is opened in the valve core 2 to communicate with the cavity, so that the inlet high-pressure oil enters the cavity to balance the pressure of the valve port, and the upper part of the valve core 2 passes through the lower cover The valve stem in the center hole of the plate 3 is processed with external thread, which plays the role of a screw, and is connected with the long nut 5. The long nut 5 is connected with the servo motor rotor 6 through the flat key 15, and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com