Heat collecting storer

A storage, heat technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat storage equipment, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

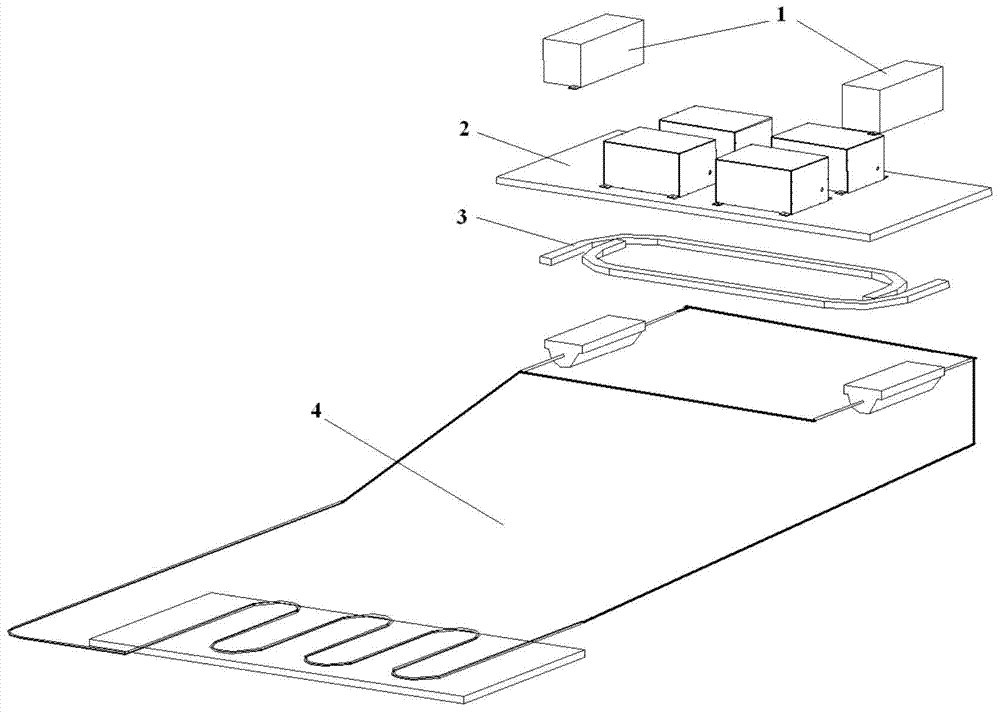

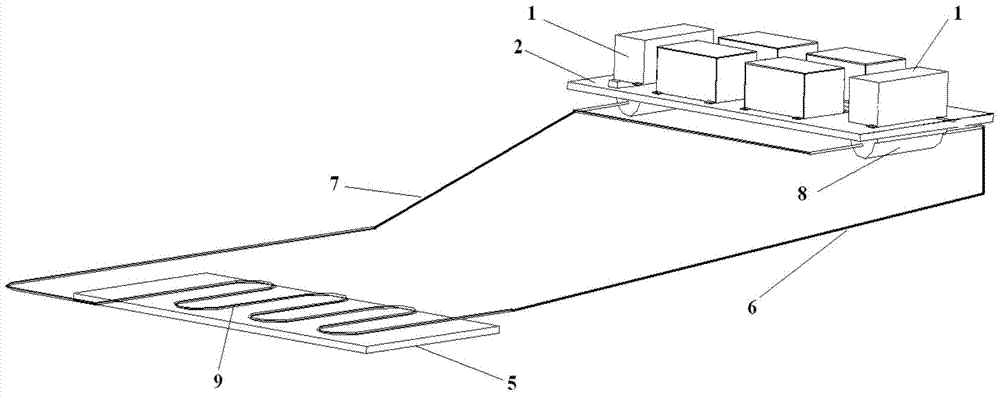

[0015] Such as figure 1 As shown, the present invention includes two phase change heat storage devices 1 , an instrument installation plate 2 , a pre-embedded heat pipe 3 and a loop heat pipe radiator 4 . The instrument mounting plate 2 is a honeycomb panel structure. The honeycomb panel structure includes a high thermal conductivity aluminum alloy skin and a honeycomb core. The thickness of the honeycomb core is 30mm, and the diameter of the honeycomb holes on the honeycomb core is 15mm. The aluminum alloy skin Covering the outer surface of the honeycomb core, the thickness of the aluminum alloy skin is 0.5mm. The middle part of the upper surface of the instrument mounting plate 2 carries the instrument that emits heat. The advantage of using the honeycomb panel as the structure of the instrument mounting plate 2 is that it can maintain a certain structural strength on the premise that the mass of the mounting plate can be effectively reduced. The pre-embedded heat pipe 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com