Experiment device and experiment method for simulating blowout depressurization of fourth-stage automatic depressurization system for reactor

A technology for simulating an experimental device and an experimental method, which is applied in the field of the fourth-stage automatic depressurization system (ADS-4) of a simulated reactor, can solve the problem of not fully simulating ADS-4 without considering the entrainment effect of mass-energy exchange. 4. Problems such as injection and pressure relief conditions, to achieve the effect of improving the safety of the experiment and reducing the electrical load of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below in conjunction with accompanying drawing:

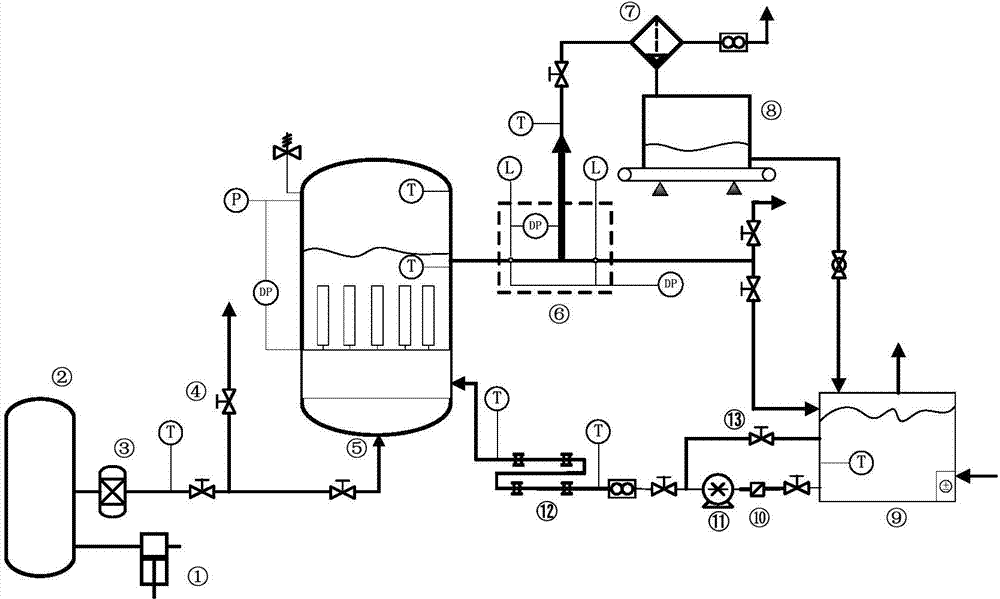

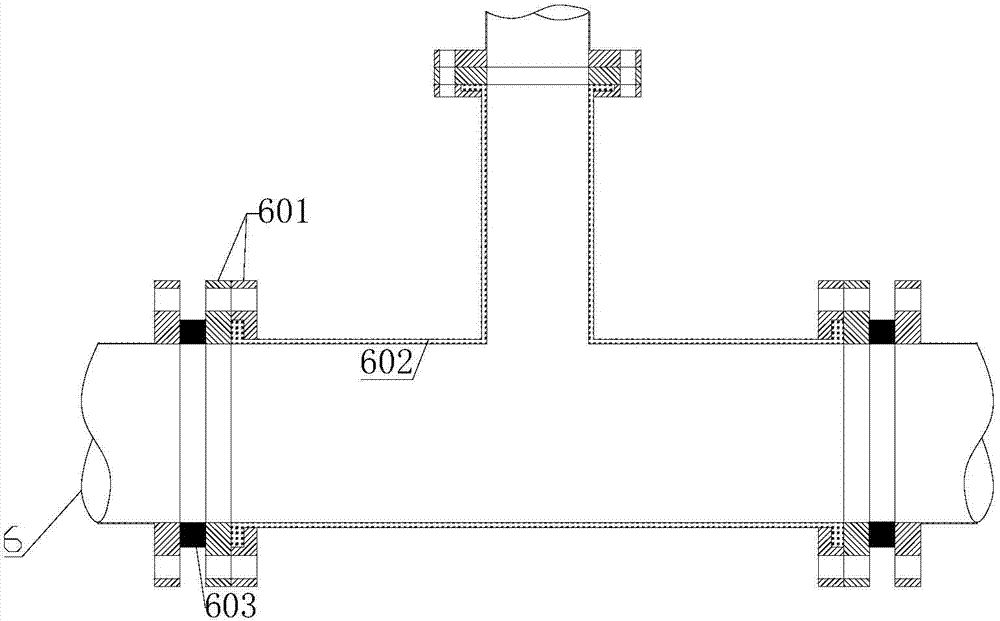

[0046] see Figure 1 to Figure 4 Said, the present invention is a reactor 4th level automatic depressurization system spray release pressure relief simulation experiment device, including air compressor 1, gas storage tank 2, first filter 3, pressure vessel 5, T-shaped pipe experiment section 6 , steam-water separator 7, catch water tank 8, heating water tank 9, second filter 10 and high temperature pump 11; Connected to the air inlet of the pressure vessel 5; the horizontal heat pipe section of the pressure vessel 5 is connected to the horizontal branch pipe of the T-tube experimental section 6; the vertical branch pipe of the T-tube experimental section 6 (equivalent to the ADS-4 branch pipe) passes through the steam-water separator 7 is connected to the catch water tank 8; the catch water tank 8 is connected to the heating water tank 9 through pipelines;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com