Method for centering and positioning self-centering positioning chuck and semiconductor wafer

A self-centering and chucking technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the positioning accuracy needs to be improved, the adaptability of the wafer diameter is not strong, and the positioning accuracy can be improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

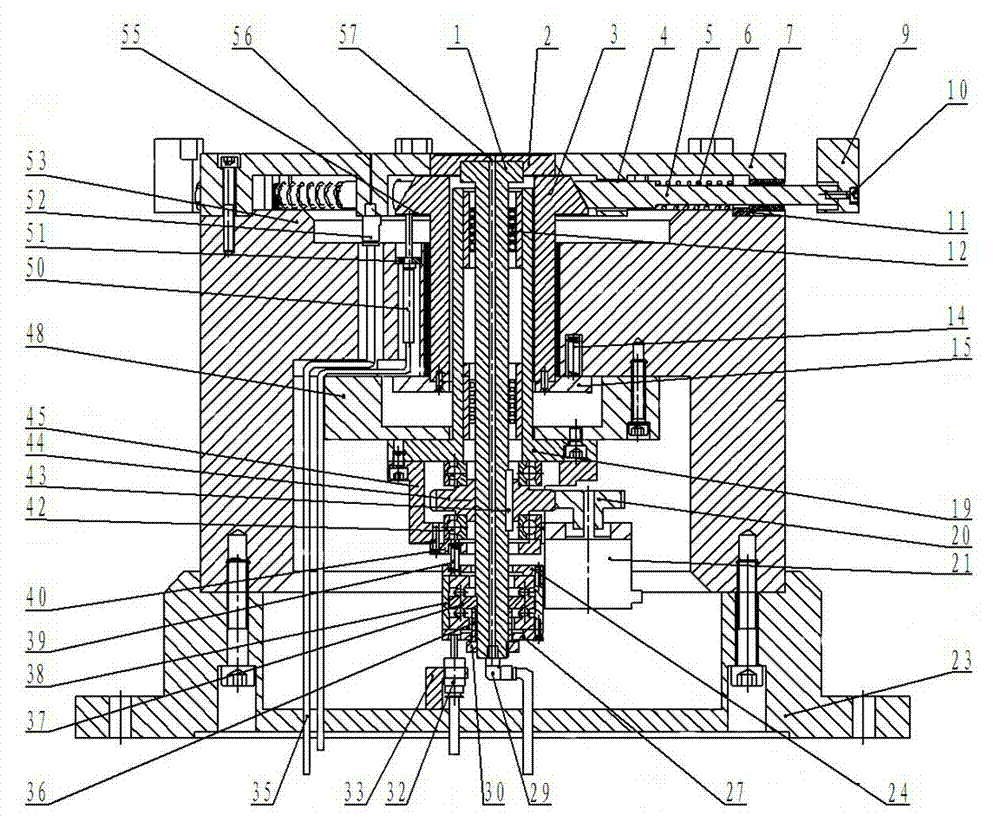

[0036] The invention relates to a self-centering positioning chuck and a centering and positioning method for semiconductor wafers. Figure 1~5 The structures and methods of the present invention are described in certain representative examples.

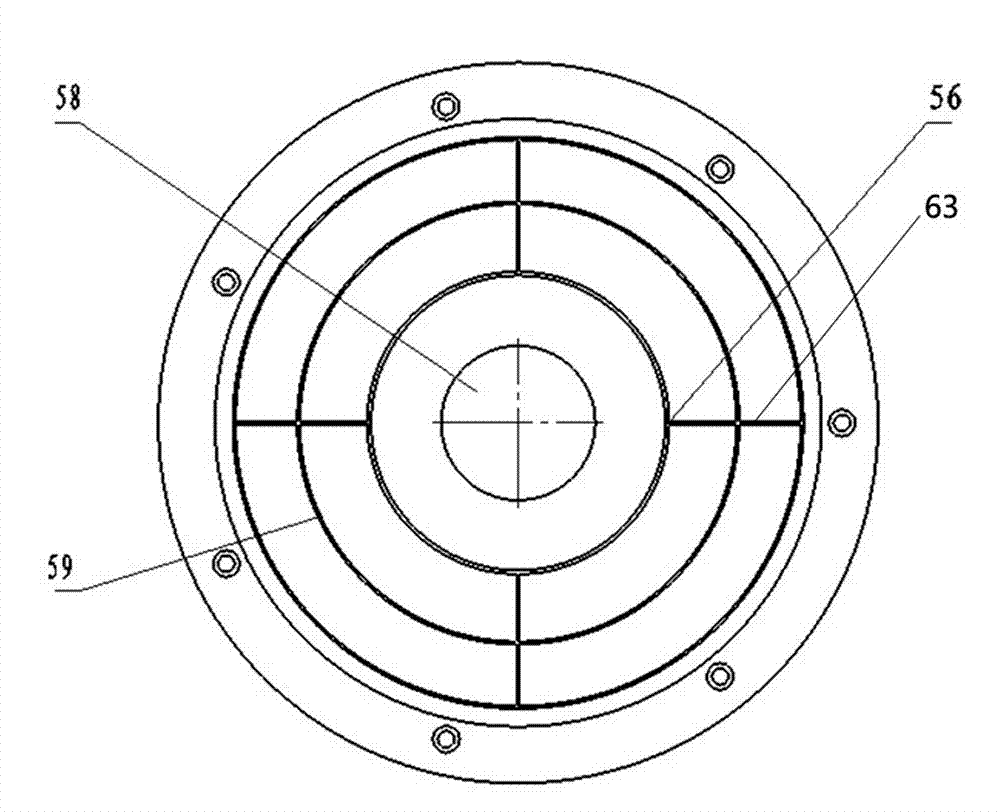

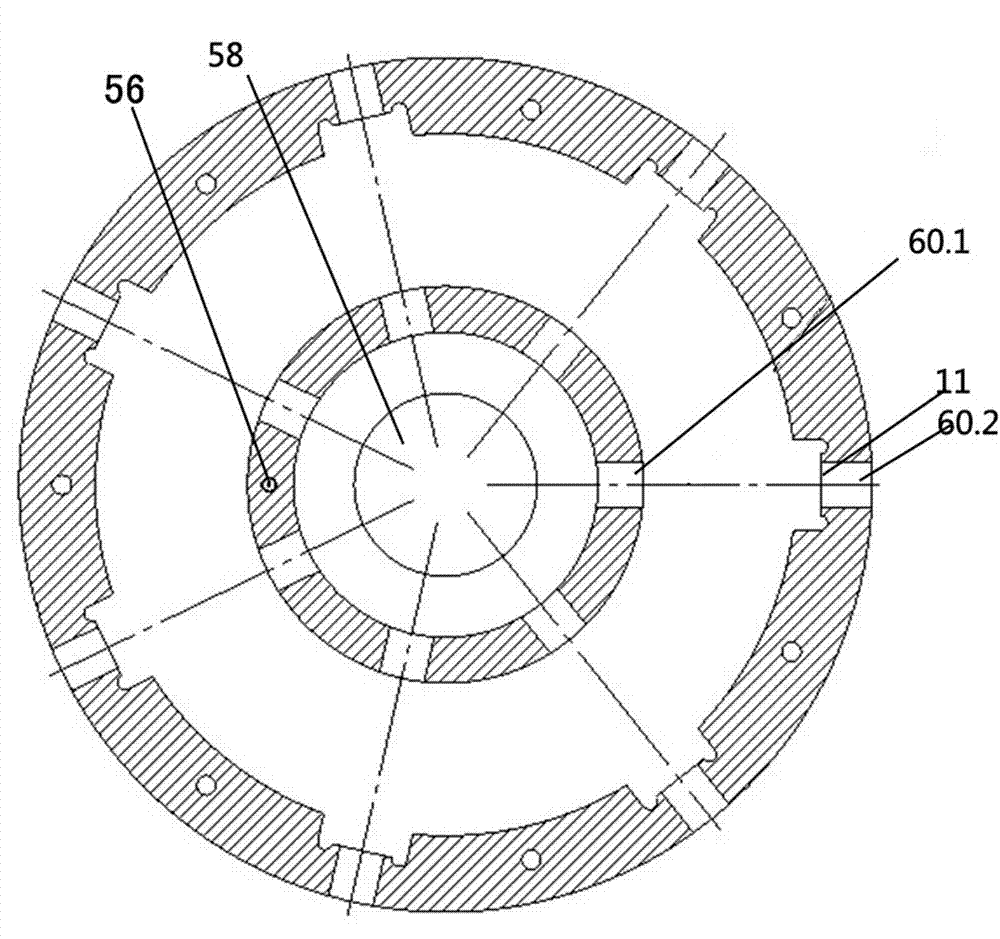

[0037] attached figure 1 The self-centering positioning chuck cuts the internal structure diagram, a self-centering positioning chuck includes a tray 7, a chuck positioning component, a central adsorption component and a chuck shell, and the chuck shell includes a base 23 and an intermediate seat The cover 53 is characterized in that: the tray 7 is a disk with a through hole 58 in the center, and two concentric inner rings 62.1 and outer rings 62.2 are fixedly connected to the lower end surface of the disk, and the inner ring 62.1 There are radial, evenly distributed inner through holes 60.1 and outer through holes 60.2 on the ring wall of the outer ring 62.2 respectively, the diameters of the inner through holes 60.1 and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com