Double-ring piezoelectric ultrasonic motor

An ultrasonic motor, double-ring type technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the complex polarization partition of piezoelectric ceramic sheets, vibration mode It is not easy to stimulate and other problems, to achieve the effect of cost reduction, motor efficiency improvement, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

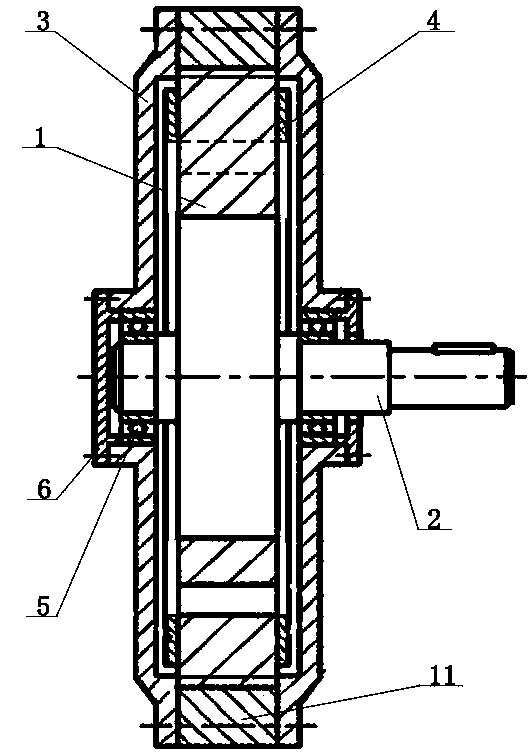

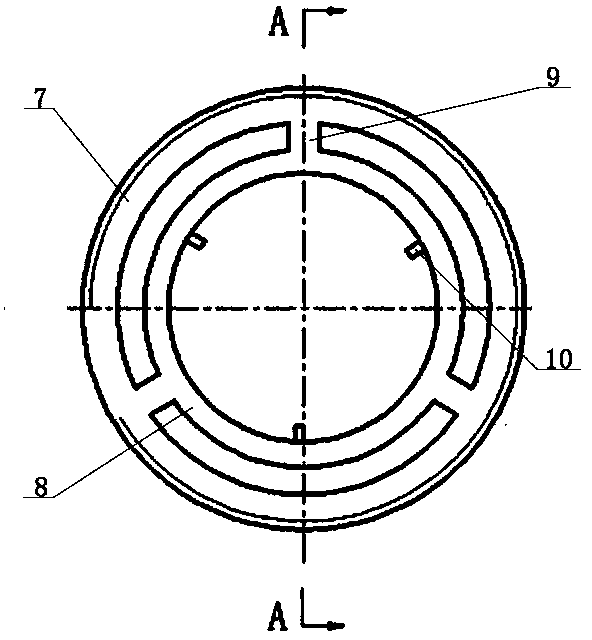

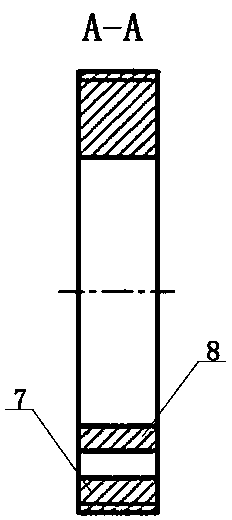

[0017] Such as figure 1 As shown, the stator 1 is housed in the cylindrical stator support 11, and the outer circular surface of the stator 1 is connected with the inner circular surface of the stator support 11 by threads, and the thread is a fine thread to ensure the installation and precise location. The ports on both sides of the stator support 11 are respectively sealed and fixed with dome-type bearing supports 3, which can seal the ports and prevent the left and right movement of the stator 1. Bearings 5 are respectively installed in the core holes of the two bearing supports 3 , the rotor 2 is a stepped shaft passing through the inner ring of the stator 1 , and the two ends of the rotor 2 are supported and connected to the two bearings 5 . The right end of rotor 2 stretches out to output power. End covers 6 are respectively sealed to the outer ends of the two bearings 5 . On the two end surfaces of the stator 1, annular piezoelectric ceramic sheets 4 are pasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com