Liquid quenching holding furnace

A holding furnace and liquid quenching technology, applied in safety devices, metal processing equipment, casting equipment, etc., can solve the problems of difficult research work, impossible to observe the evolution of the internal structure of metals, and the inability to continuously explore the role of metal solidification process, etc. To achieve the effect of controllable and solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

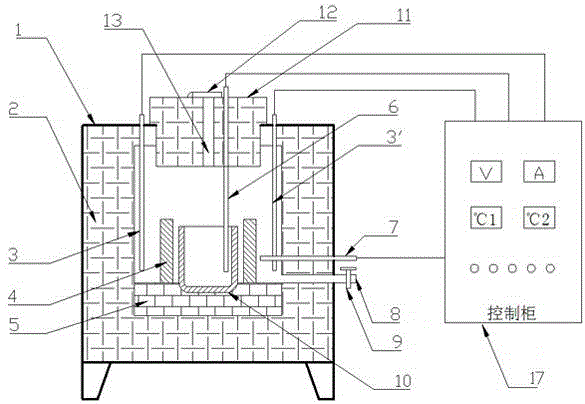

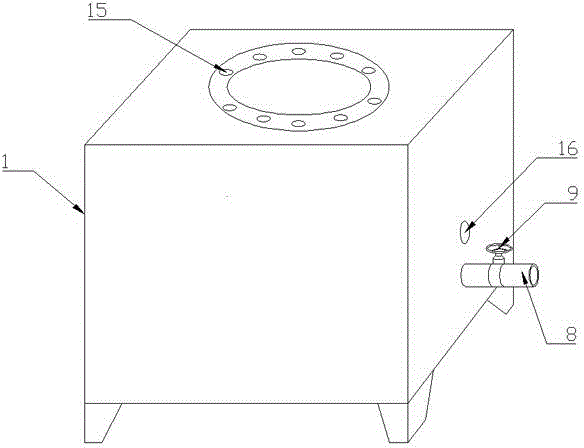

[0021] Example 1: The smelted liquid quenching sample of ductile iron can choose a silicon molybdenum rod as the heating rod (3), and assemble it through the 10 heating rod insertion holes (15) above the furnace body (1) after selection.

[0022] Select argon as the inert gas, and connect it through the inert gas inlet tube (8).

[0023] The minimum temperature of the control cabinet (17) is set to 1150°C, the inert gas is introduced to discharge the air, the electricity is heated to the set temperature, and the crucible (10) can be put into it for preheating.

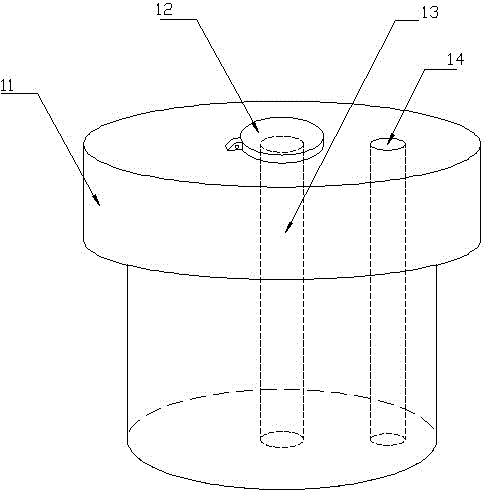

[0024] The spheroidized molten iron is poured into the preheated crucible (10) at 1350°C, and then quickly transferred to the furnace, and the pre-designed annular cold iron (4) is selectively added according to the cooling rate requirements , cover the furnace cover (11), stop the delivery of inert gas, and close the air flow control valve (9).

[0025] Extract the liquid quenched sample according to the temperature ...

Embodiment 2

[0027] Example 2: A liquid quenching sample for Al-Si alloy smelting A silicon carbide rod can be selected as the heating rod (3), and assembled through the 10 heating rod insertion holes (15) above the furnace body (1) after selection.

[0028] Select argon as the inert gas, and connect it through the inert gas inlet tube (8).

[0029] The minimum temperature of the control cabinet (17) is set to 585°C, the inert gas is introduced to discharge the air, the electricity is heated to the set temperature, and the crucible (10) can be put into it for preheating.

[0030] Inject the molten aluminum into the preheated crucible (10) at 720°C and quickly transfer it to the furnace, and selectively add the pre-designed annular chiller (4) according to the cooling rate requirements, cover Put on the furnace cover (11), stop the delivery of inert gas, and close the air flow control valve (9).

[0031] Extract the liquid quenched sample according to the temperature displayed on the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com