Silver printing positioning template of piezoelectric ceramic pieces and silver printing method of piezoelectric ceramic pieces

A technology of piezoelectric ceramic sheets and positioning templates, applied in printing, printing machines, printing devices, etc., can solve the problems of high labor intensity, cumbersome operation, and inability to meet large-scale production, and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

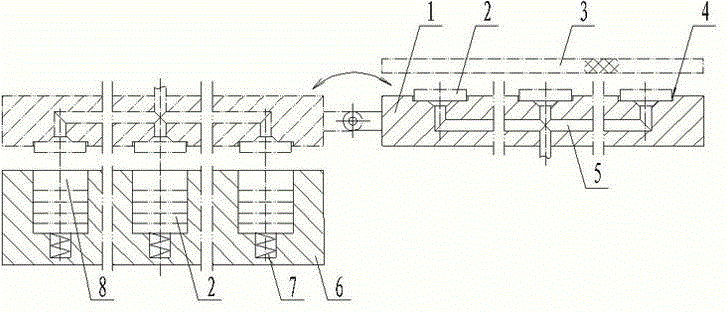

[0015] The positioning template provided by the present invention is as figure 1 As shown: the positioning plate 1 is hinged on the workbench (not shown in the figure) of the silver printing machine. There are several positioning holes 4 distributed on the surface of the positioning plate, and each positioning hole 4 passes through the air passage 5 arranged inside the positioning plate 1 It communicates with the vacuum pump (not shown in the figure) of the silver printing machine; a material plate 6 is fixed on the workbench, and a number of storage holes 8 corresponding to the positions of the positioning holes 4 are distributed on the surface of the material plate, and each material storage hole 8 There is spring 7 in it.

[0016] like figure 1 Shown, the operating steps of the inventive method are as follows:

[0017] 1) Stack two layers of pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com