A kind of preparation method of high-purity nitric acid

A nitric acid, high-purity technology, applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of high cost, cumbersome operation, unstable product quality, etc., and achieve low cost, simple operation process, and good removal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

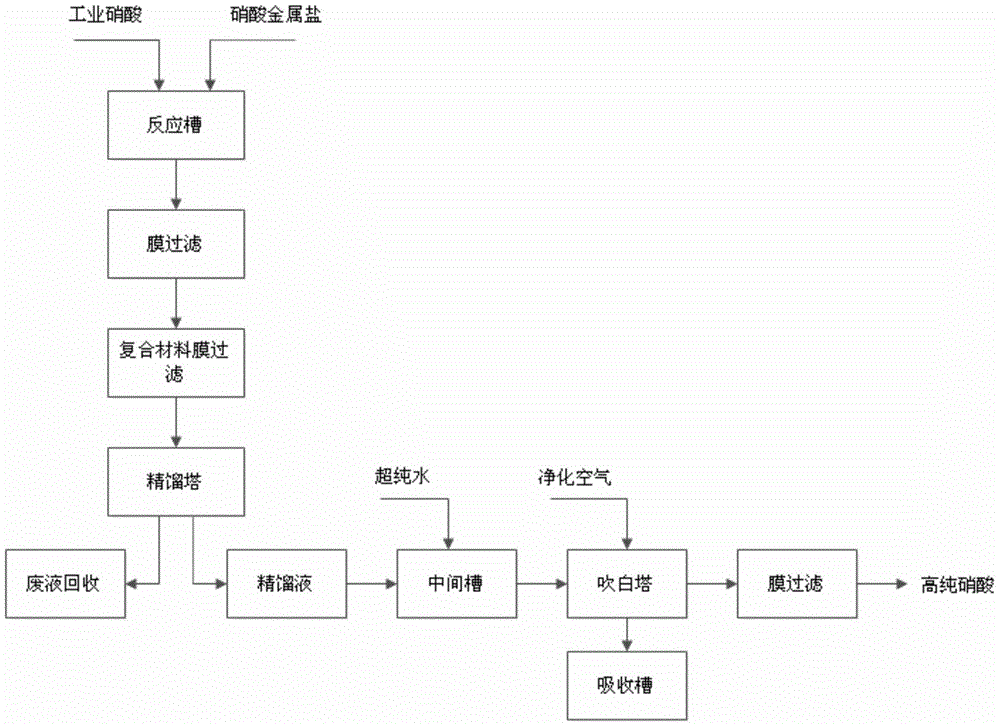

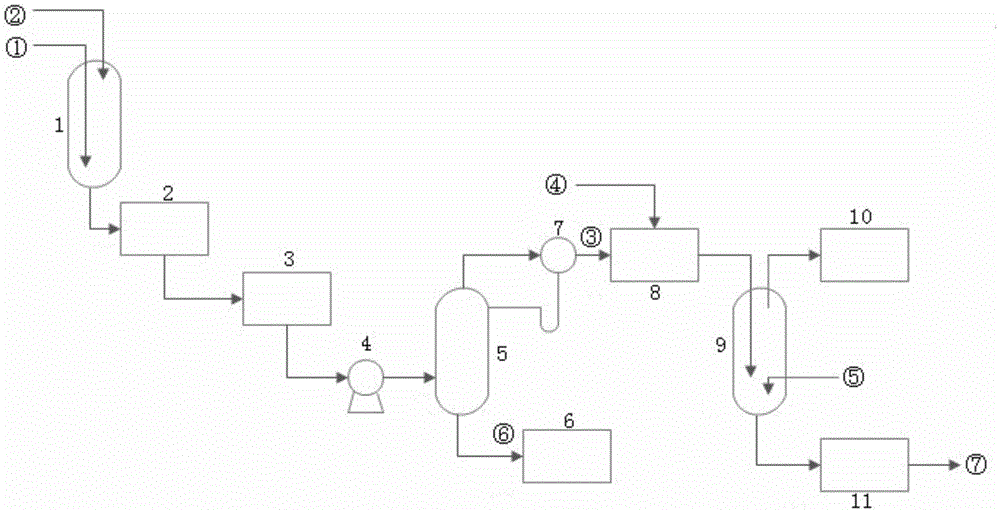

Method used

Image

Examples

Embodiment

[0030] 1. Preparation of melamine-formaldehyde-thiourea resin / polyacrylic acid resin composite film

[0031] Mix melamine, formaldehyde, thiourea, and polyacrylic acid resin at a molar ratio of 2:12:1:0.01, dissolve in deionized water, add NaOH solution to adjust pH=8.5-9.0, and react at 90°C for 2.5h. Then use HCl solution to adjust PH = 5, react at 120°C for 1.0h, wash and dry the obtained polycondensation product and mix it with polyacryl alcohol binder at a mass ratio of 5:3, at 85-90°C The composite membrane is made by sintering, and the obtained composite membrane is washed with high-purity nitric acid for use.

[0032] 2. Industrial grade nitric acid pretreatment

[0033] The silver nitrate and barium nitrate solution of 1-10wt% is prepared by ultrapure water and silver nitrate and barium nitrate respectively. Add 75-80wt% industrial grade nitric acid into the preprocessor 1, add 1-10wt% silver nitrate solution or barium nitrate solution dropwise under stirring at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com