Sift-proof loader bucket manufacturing method

A manufacturing method and loader technology, applied to mechanically driven excavators/dredgers, etc., can solve the problems of bulk material leakage, bulk material recovery and cleaning time-consuming and laborious, etc., and achieve simple structure, simple manufacture, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

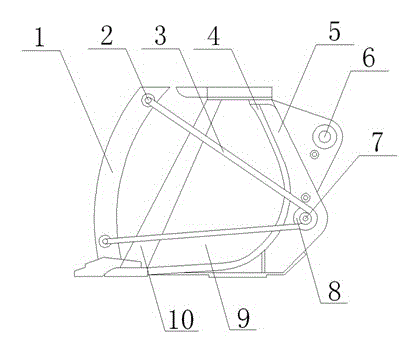

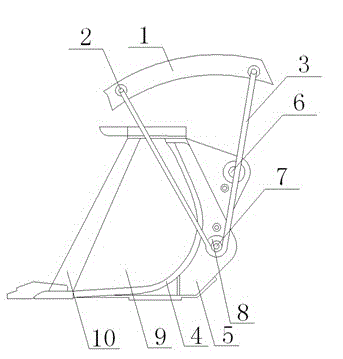

[0021] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the use status diagram of the present invention.

[0022] A kind of manufacturing method of the anti-spill loader bucket of the present invention, wherein, comprise the following steps: A, weld and fix the rib plate on the inner arc wall of "C" shape bucket, make the rib plate and "C" shape shovel The inner arc wall of the bucket fits together, the side guard plate is welded and fixed on the "C" shaped bucket, the beam is welded and fixed at the opening of the "C" shaped bucket next to the side guard plate, and the arc of the "C" shaped bucket is welded and fixed. Welding and fixing the motor, socketing the rotating shaft on the output shaft of the motor, welding and fixing the rotating arm on the rotating shaft, setting a flat plate at the opening of the rotating arm, and setting fixing bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com