Hoisting system of drilling machine

A technology for lifting systems and drilling rigs, applied to drill pipes, drill pipes, drilling equipment, etc., to achieve the effect of convenient transportation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

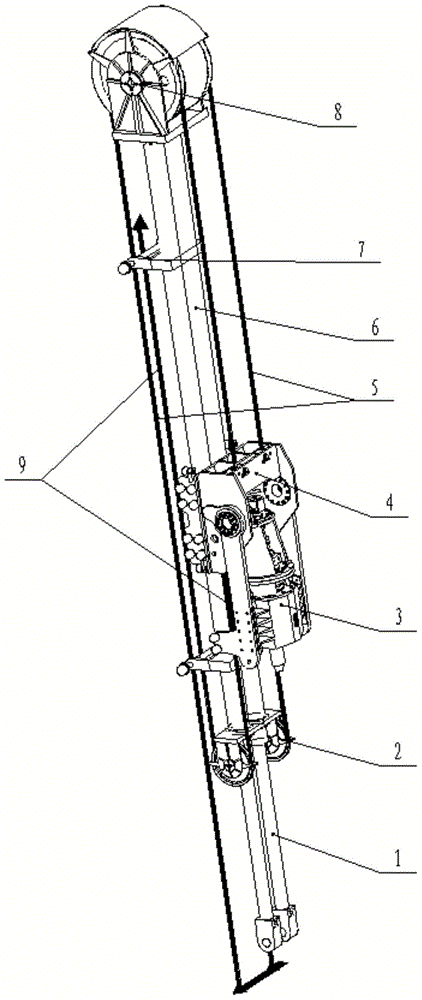

[0025] Example 1, taking a lifting system as an example, further describes the present invention in detail. see figure 1 , the main body of the lifting device of the drilling rig is an inverted hydraulic cylinder composed of a hydraulic cylinder (6) and a hydraulic cylinder rod (1), which is installed on the bottom plate of the derrick through a pin shaft. The weight generated in the derrick acts on the bottom of the derrick, with a low center of gravity and good stability.

[0026] The hydraulic cylinder in the lifting system is installed upside down inside the derrick, and the piston rod (1) is connected with the hinge seat pin on the derrick connecting plate. The force generated by the hydraulic cylinder directly acts on the connecting plate at the lower part of the derrick. The main force, the main function of the upper derrick is to provide guide rails for the movement of the power head and the lifting device and to withstand the reaction torque generated during the dril...

Embodiment 2

[0033] Embodiment 2, taking the working principle of the lifting system as an example, further introduces in detail, in order to deeply understand the lifting system of the present invention.

[0034] Lifting process:

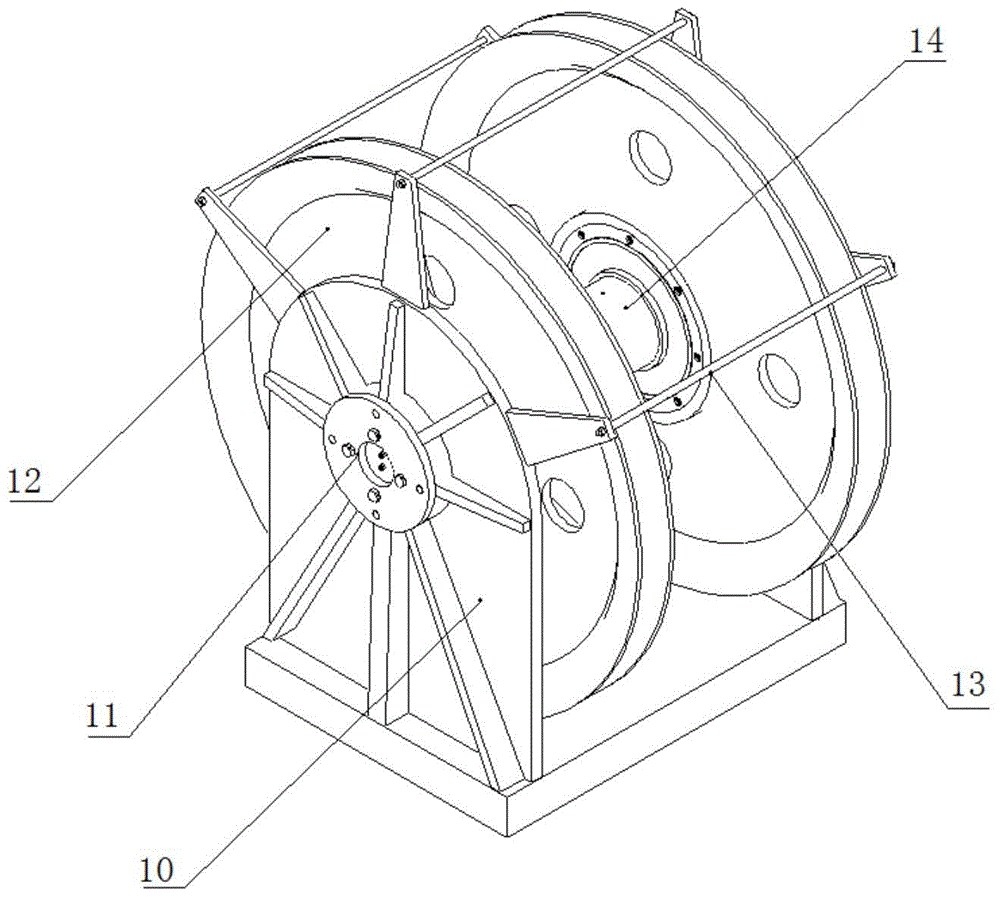

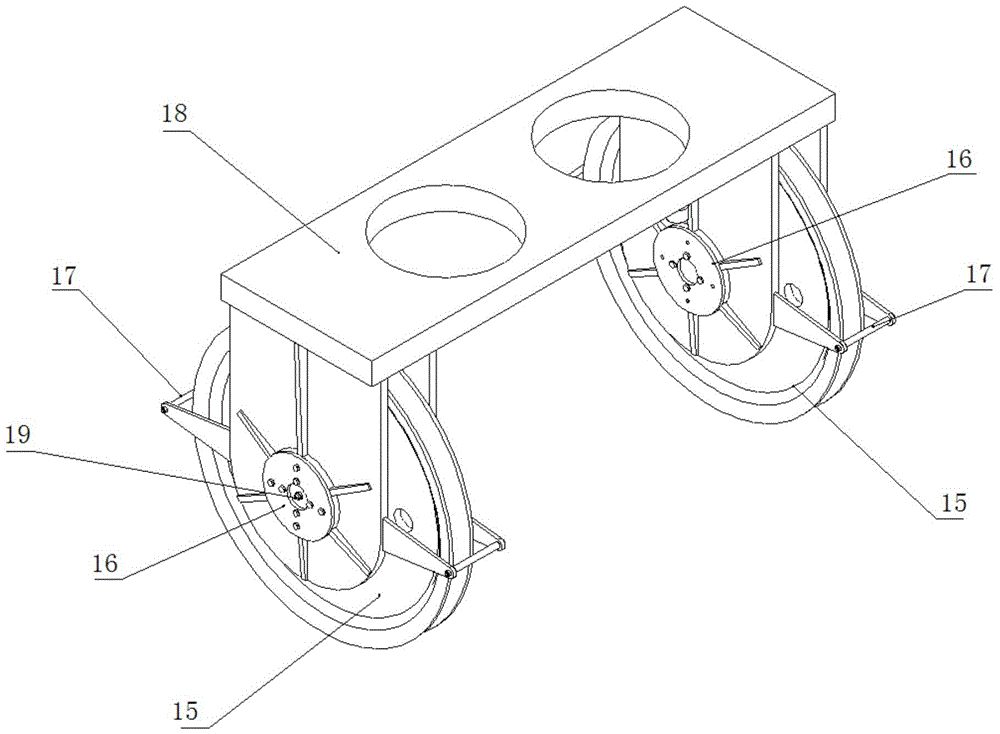

[0035] When the hydraulic cylinder is stretched out, one end of the lifting wire rope is connected to the pulley, and the other end goes around the pulley block of the upper lifting assembly and is fixed at the lower end of the derrick. The hydraulic cylinder extends to a maximum stroke of 7 meters, and the upper lifting pulley block (moving pulley) rises 7 meters. According to the working principle of the movable pulley, the steel wire rope drives the pulley and the power head to rise up to a distance of 14 meters, thereby realizing the doubling of the stroke. The drill string is lifted by the force generated by the hydraulic pressure of the plug chamber of the hydraulic cylinder. During this process, the steel wire rope is pressed down and moves accordingly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com