Stratum deep high-salinity brine exploitation and heat utilization system

A high-salt and brine technology, which is used in systems for heat exchange with high-salt brine and systems for producing high-salt brine in deep formations, can solve the problems of waste of clean water, low compressibility, and increased engineering costs, and achieve The effect of reducing environmental pollution, reducing waste of resources and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and embodiments, but the protection scope of the present invention is not limited to the following embodiments.

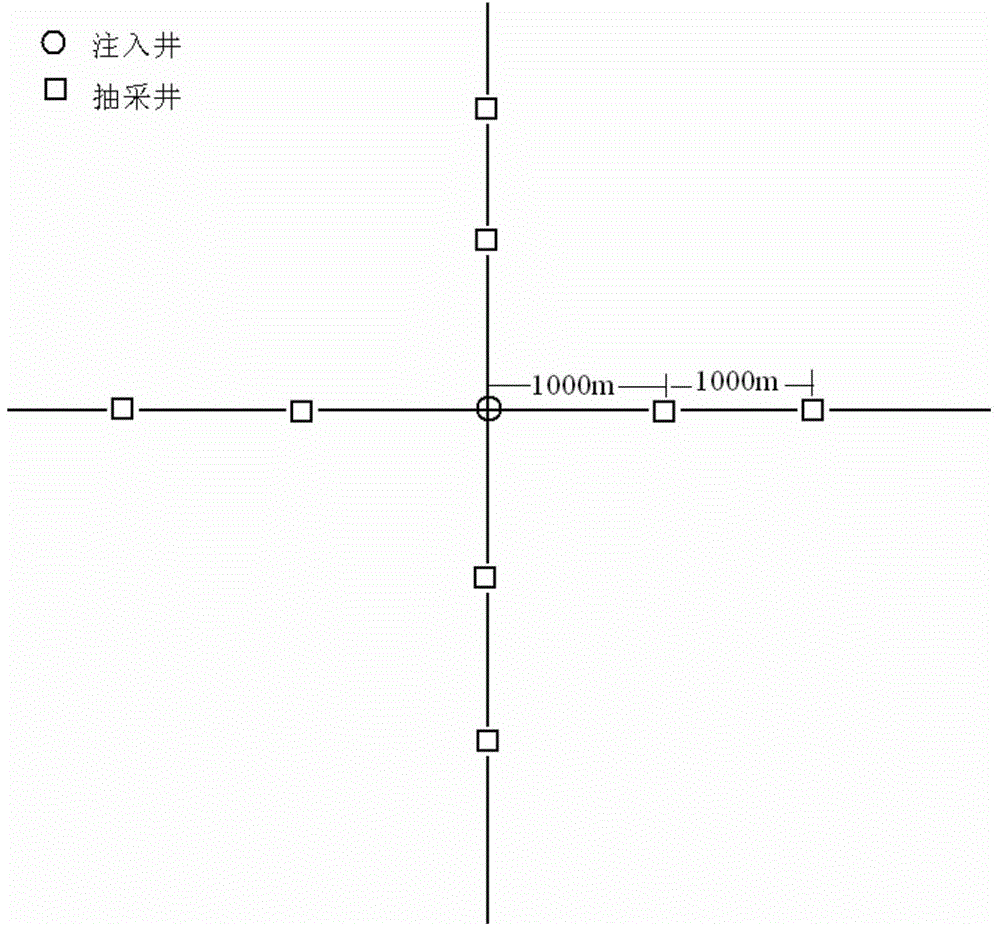

[0016] Drill wells should be carried out before mining, and the corresponding drainage wells and injection wells should be drilled. In this embodiment, the distribution of drainage wells and injection wells is as follows: figure 1 As shown, the drainage wells are distributed in a cross shape, the injection wells are located in the center of the cross shape, and the drainage wells are distributed outwardly with the injection well as the center, and the gap between the injection well and the adjacent extraction well The distance is 1 km, and the distance between adjacent extraction wells is 1 km.

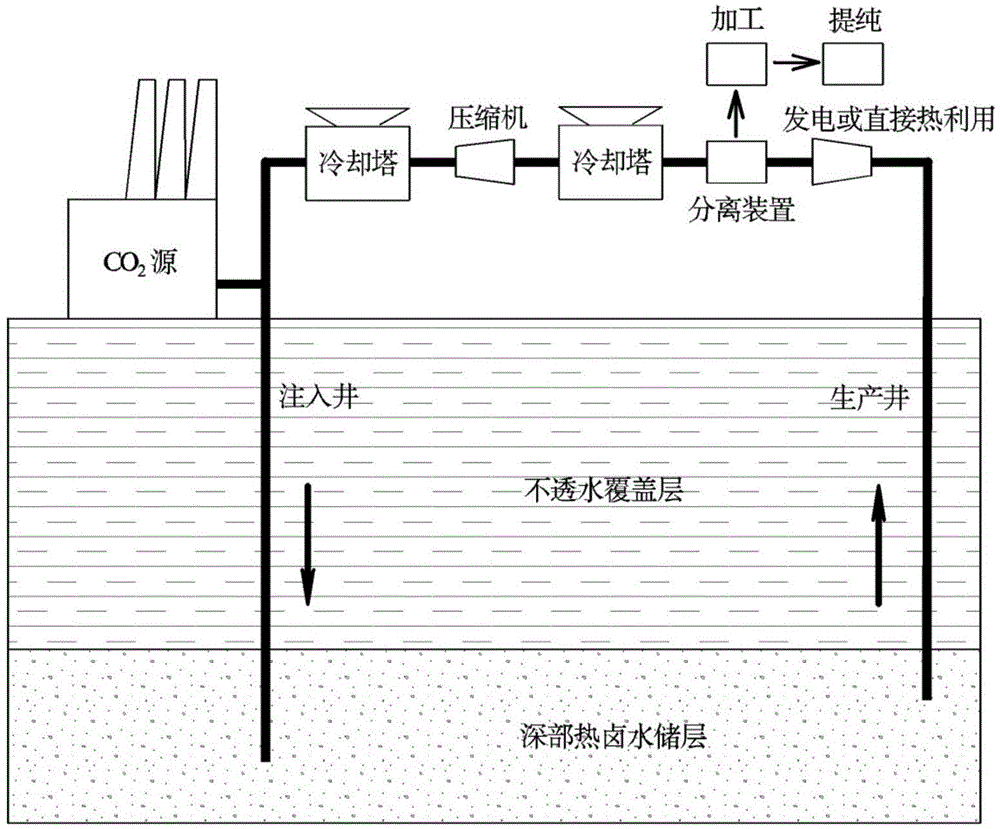

[0017] The mining and heat utilization system of deep high salt brine provided by this embodiment is as figure 2 Shown:

[0018] Including injection wells, extraction wells, CO 2 Sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com