Continuous gel and pasty propellant supply device for rocket engine

A rocket engine and supply device technology, which is applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problems that the scope of application is only in the test and principle research, and the continuous supply requirements of propellants cannot be met. To achieve the effect of compact structure, high machining precision and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

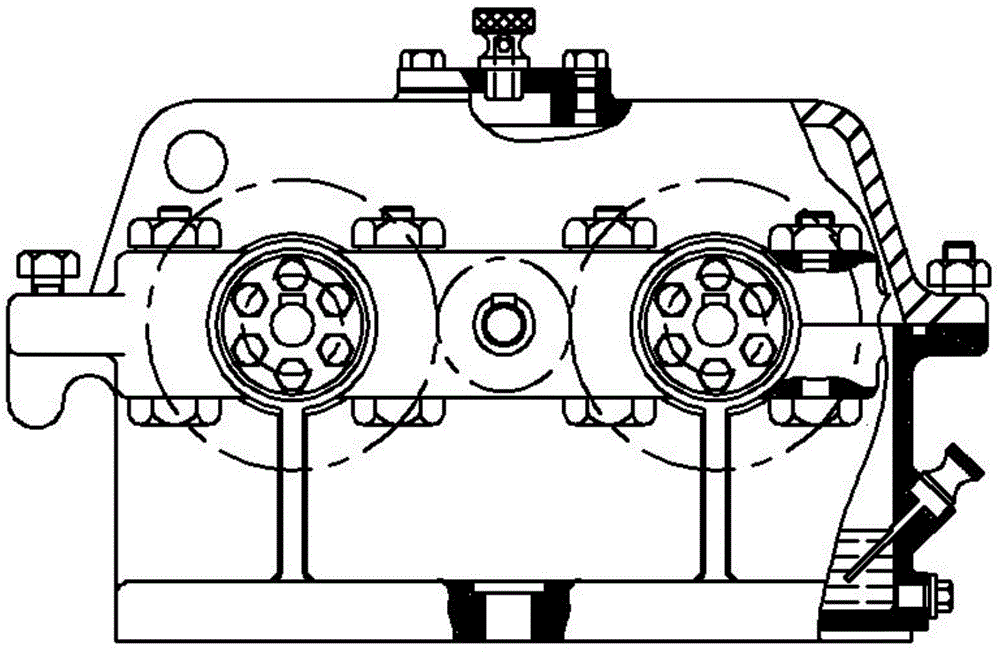

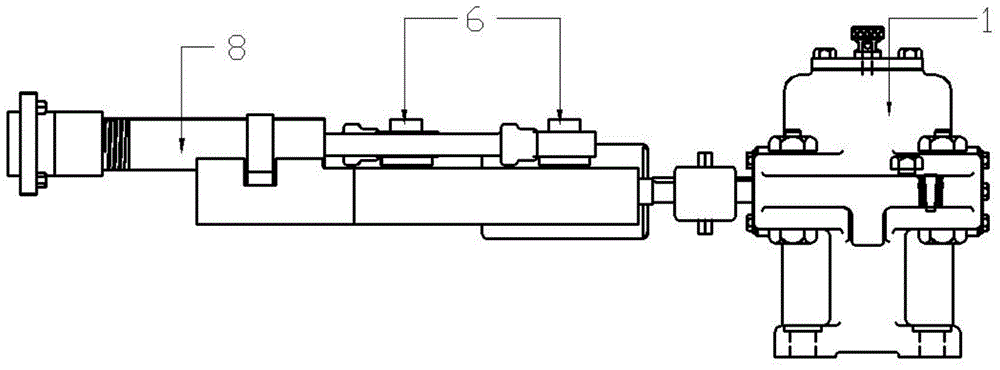

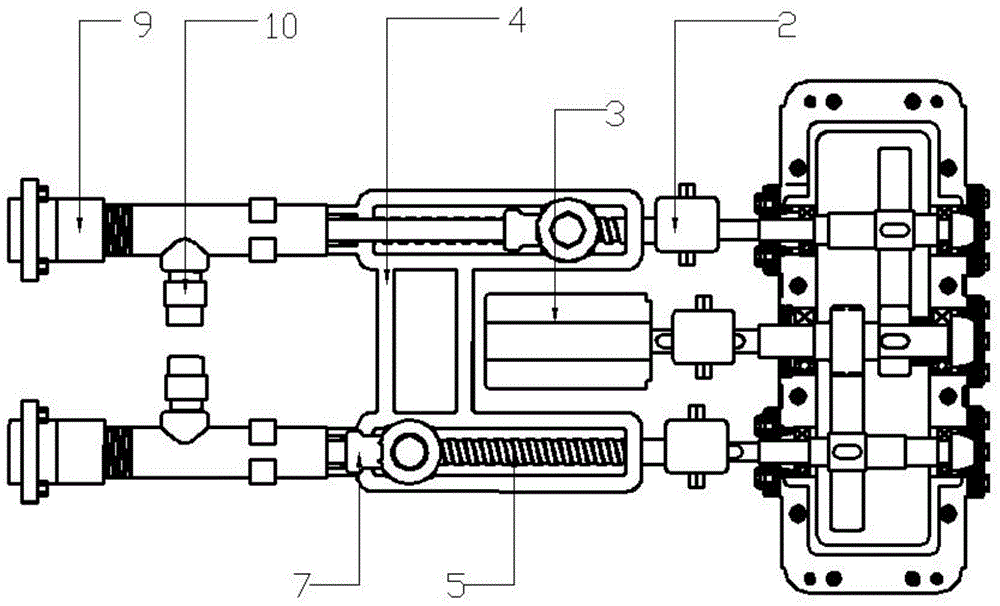

[0020] combine Figure 1 to Figure 5 :

[0021] A continuous supply device for gel paste rocket engine propellant, including a mechanical transmission device, a piston supply and transportation device, and a propellant storage and output device, the mechanical transmission device, a piston supply and transportation device, and a propellant storage and output device are all Set on the workbench; the transmission device includes a reduction box 1, a coupling 2, a servo motor with adjustable speed 3, a ball screw base 4, a ball screw 5, and a nut slider 6; the piston supply and transportation device includes a piston Sleeve rod 7, piston cylinder 8, piston cylinder end check valve 9 and piston cylinder side check valve 10; propellant storage and output device includes transition chamber 11 and propellant storage tank 12; The motor shaft of the adjustable servo motor 3 is fixedly connected to the reduction box 1 through the coupling 2; The input shaft and output shaft of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com