Device and method for dynamic testing of contact pressure of contact terminal of alternating-current contactor

A technology of AC contactor and contact pressure, applied in the direction of measuring device, force/torque/power measuring instrument, instrument, etc., can solve the problem of not being able to accurately obtain the dynamic signal of the contact pressure of the contactor of the AC contactor, and achieve a good man-machine The effect of interactive operation interface, high precision and wide range of force measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: (detailed in conjunction with accompanying drawing):

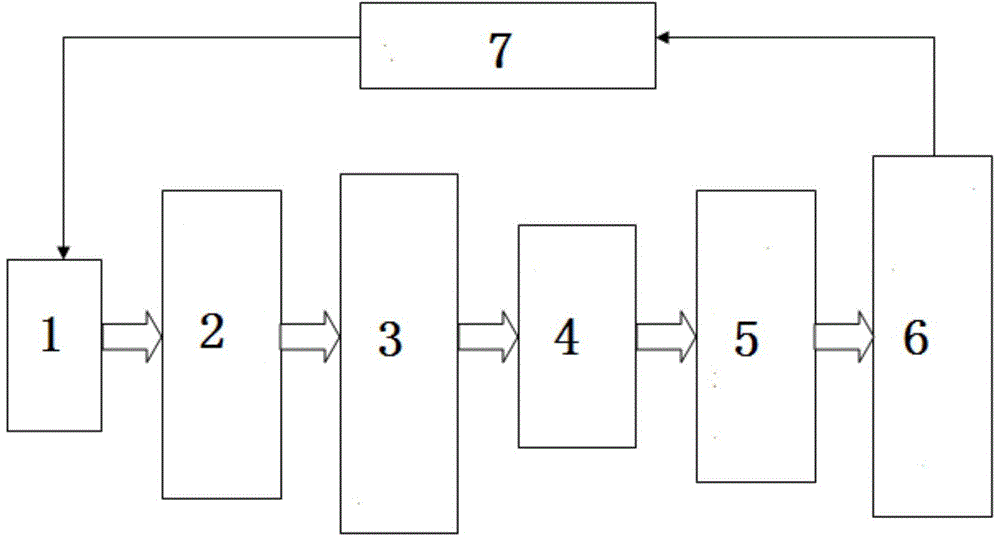

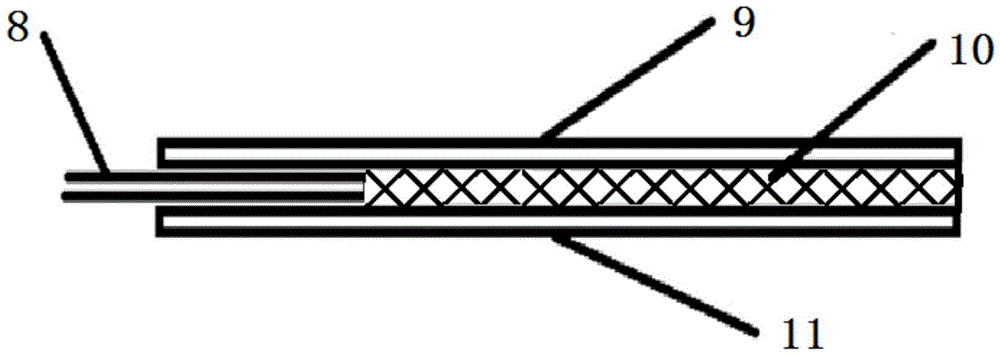

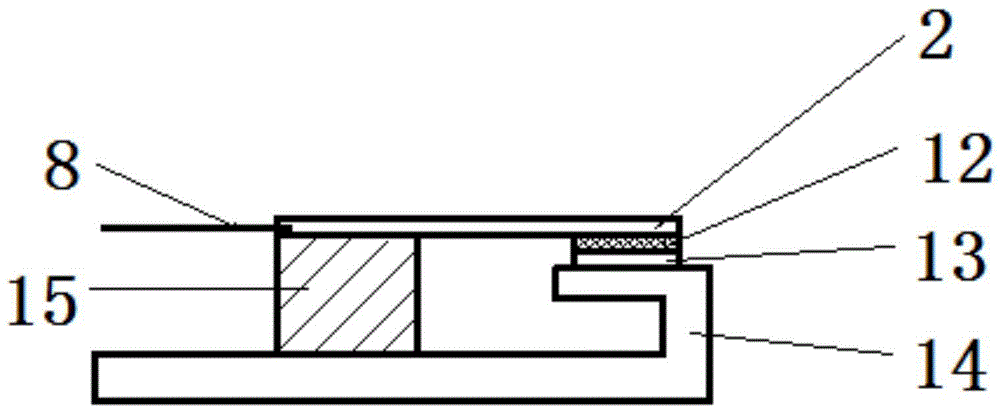

[0045] The composition of AC contactor contact pressure dynamic testing device of the present invention is as follows: figure 1 As shown, it is divided into upper computer and lower computer; the upper computer is an industrial computer (6), and the lower computer includes: contact contact pressure sensor (2), charge amplifier (3), signal conditioning circuit (4), high-speed data acquisition card (5), closing phase angle controller (7); AC contactor (1) is the test sample.

[0046] The connection method is: the contact contact pressure sensor (2) is bonded to the contactor test object (1), the signal output end of the contact contact pressure sensor (2) is connected to the charge amplifier (3) through the shielded wire; the charge amplifier ( The output end of 3) is connected to the signal conditioning circuit (4) through a shielded wire; the output end of the signal conditioning circuit (4) is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com