Plane type ejection launch carrier-borne aircraft front undercarriage static force test loading apparatus

A technology of loading device and front landing gear, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of increasing the complexity of the test support system, changing the load transmission path, and increasing the difficulty of test loading, etc. , to achieve the effect of reasonable distribution of loading points, small site requirements, and wide field of vision for test observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

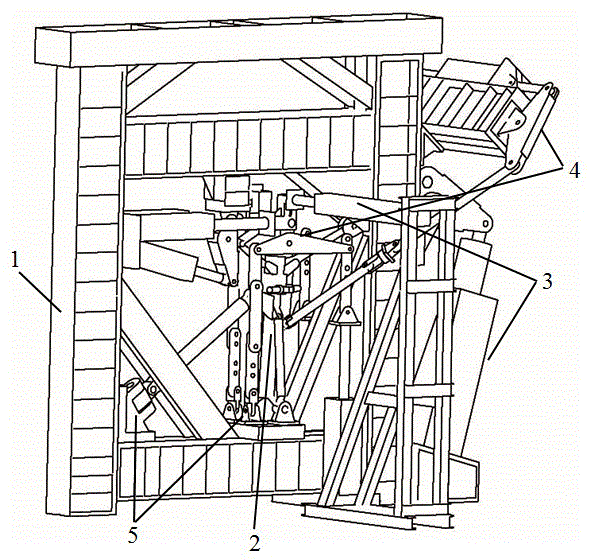

[0027] The overall installation diagram of the static test is as follows: figure 1 As shown, it includes a planar test bench 1, an undercarriage 2, and a side load loading device, a heading load loading device, a vertical load loading device, an ejection load loading device, and a pinning load loading device for loading loads through a loading actuator 3. device and tethered load loading device. For the static loading test of the nose landing gear of the catapult take-off carrier aircraft, the landing gear 2 needs to be installed upside down on the test bench 1, and the landing gear and the test bench are connected by the supporting fixture 5 and the loading fixture 4.

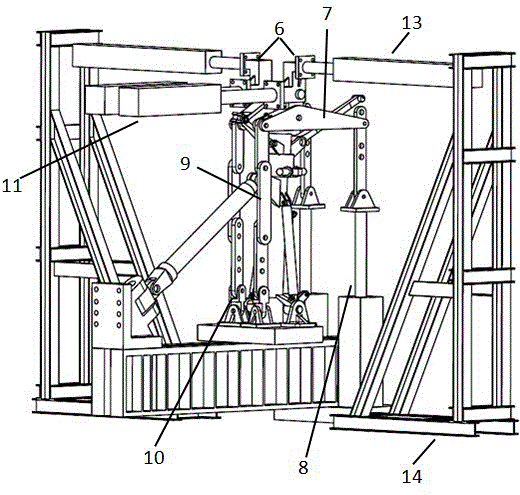

[0028] figure 2 Schematic diagram of three-way loading at the wheel axle. For the nose landing gear of a catapult take-off carrier-based aircraft, the side load is relatively small, and the load conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com