Monitoring method for accumulative low-cycle fatigue life loss of thermal power generation unit components

A thermal power generation unit, low-cycle fatigue technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of low-cycle fatigue damage, large size, and high cost of important components of thermal power generation units, and achieve guarantee The effect of long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

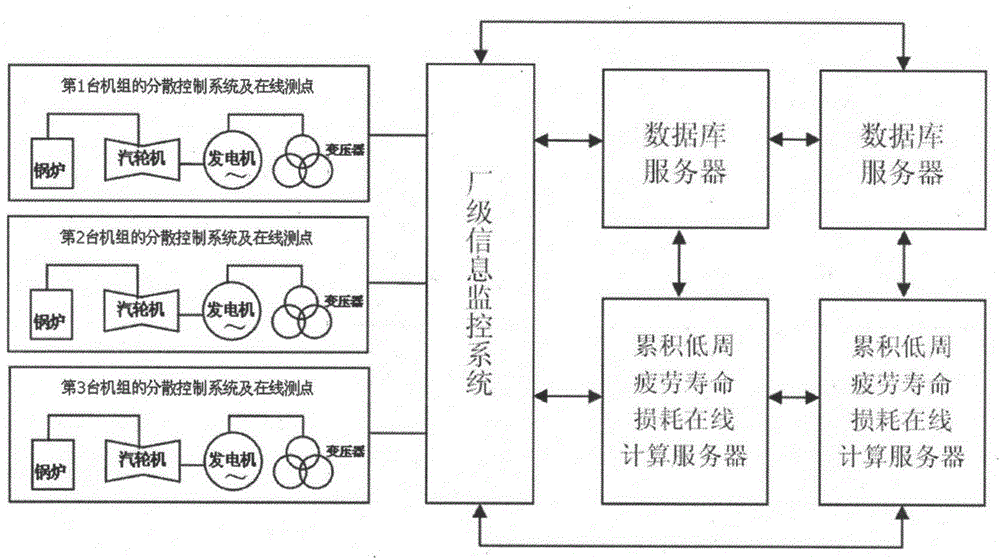

[0078] Such as figure 1 As shown, it is a block diagram of the online monitoring and control device adopted in the present invention, the cumulative low cycle fatigue life loss online monitoring and control device of the important parts of the thermal power generating set is composed of a dual redundant cumulative low cycle fatigue life loss online calculation server , dual-redundant database server and plant-level monitoring information system (SIS system), the cumulative low-cycle fatigue life loss online calculation server is connected to the database server, and the database server is connected to the distributed control system (DCS) of thermal power generation units through the plant-level monitoring information system ) and online measuring point connection.

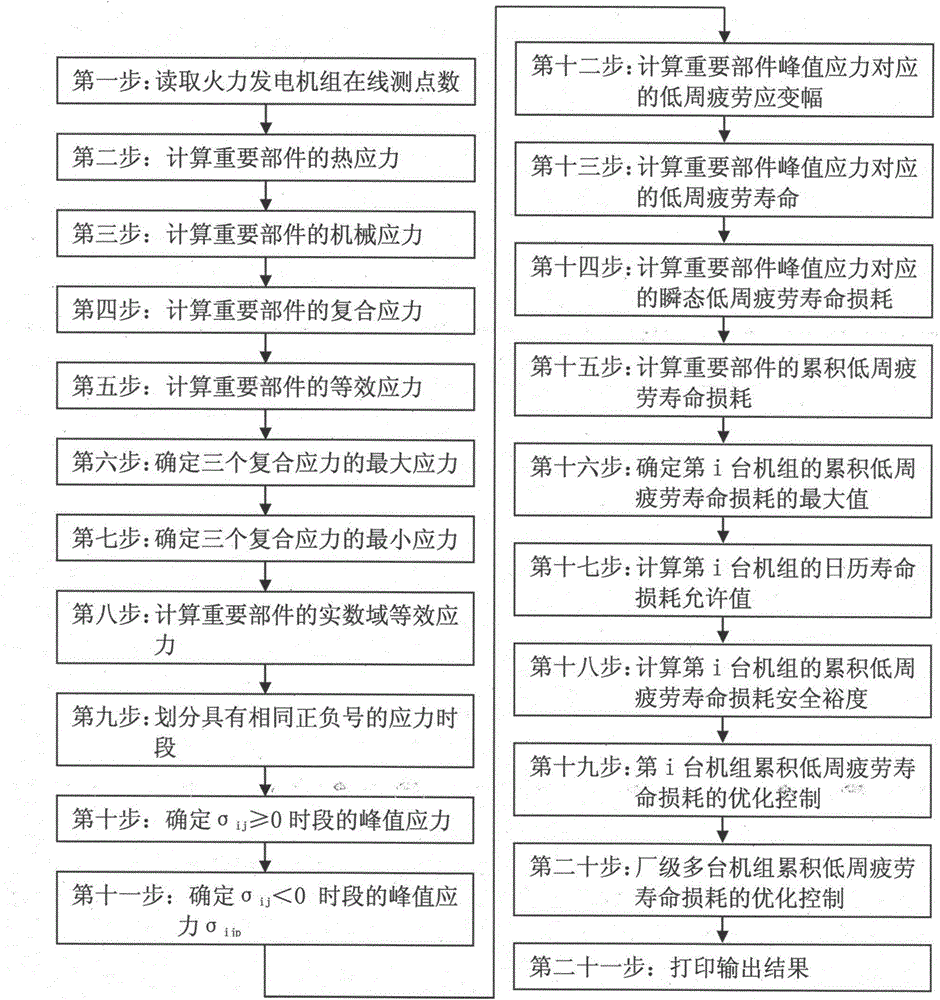

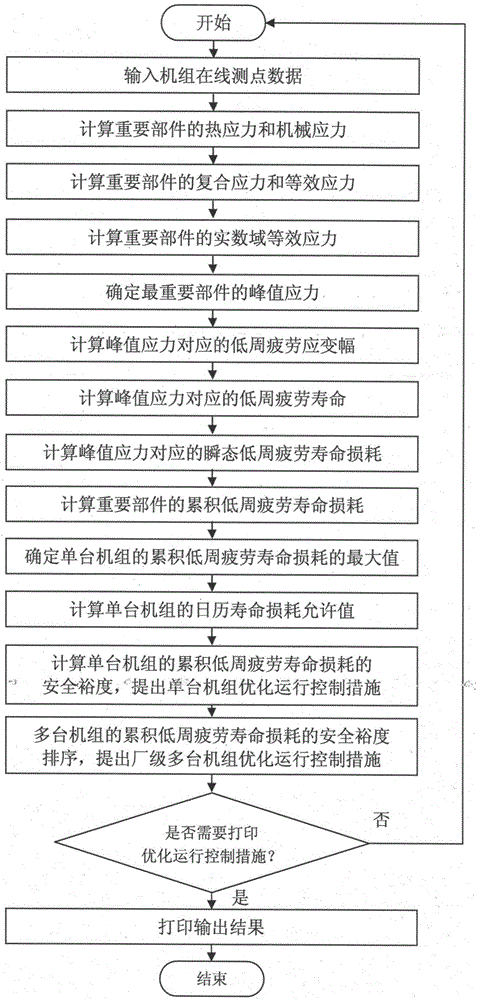

[0079] Such as figure 2 Shown, is the flowchart of the method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com