Metal closed solid insulation pole-mounted vacuum switch

A solid insulation and metal-enclosed technology, applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of limited use of insulating vacuum switchgear, small internal space, leakage environment, etc., to avoid water vapor The effect of entering the inner cavity of the pole, preventing condensation, and reducing airtightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

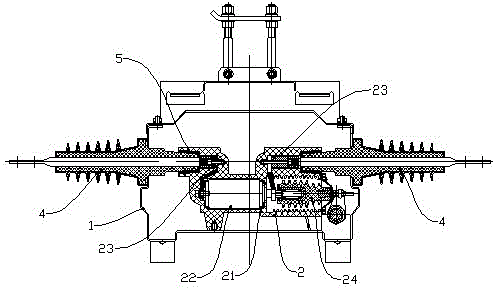

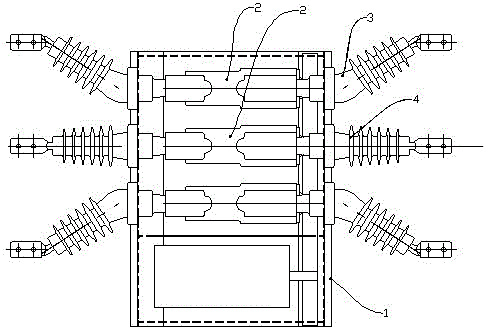

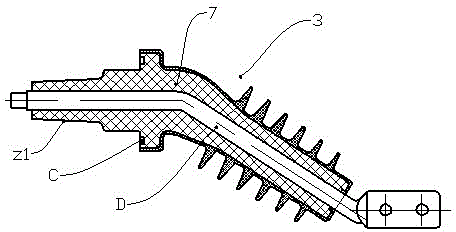

[0016] Such as figure 1 , figure 2 As shown, the vacuum switch on the metal-enclosed solid insulating column includes a metal box 1, and three-phase poles 2 are arranged side by side in the box 1; the poles include an insulating cylinder 21, which is sealed in the insulating cylinder The vacuum interrupter 22, the outlet conductor 23 located in the insulating cylinder and respectively connected to the moving contact and the static contact of the vacuum interrupter, and the insulating pull rod 24 located in the inner cavity of the insulating cylinder to drive the moving contact; Two-phase bent outlet sleeves 3 and one phase straight outlet sleeve 4 are respectively installed on the front and rear wall panels of the box body 1; One end of the straight outlet sleeve 3 and the bent outlet sleeve 4 is located in the box and connected to the end of the pole, and the other end of the straight outlet sleeve 3 and the bent outlet sleeve 4 is located in the box On the outer side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com