Through hole polishing device for through hole polishing by utilizing negative pressure and method thereof

A polishing device and negative pressure technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. Realize problems such as automatic polishing, and achieve the effect of improving efficiency, saving labor costs, and reducing air tightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

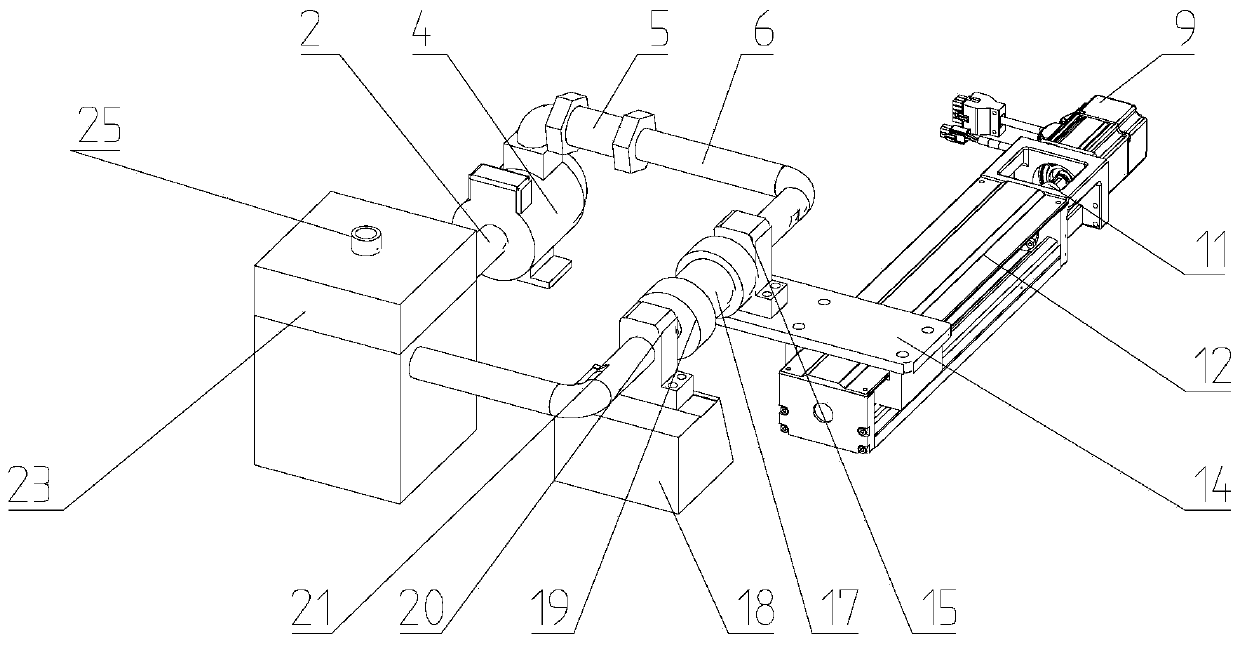

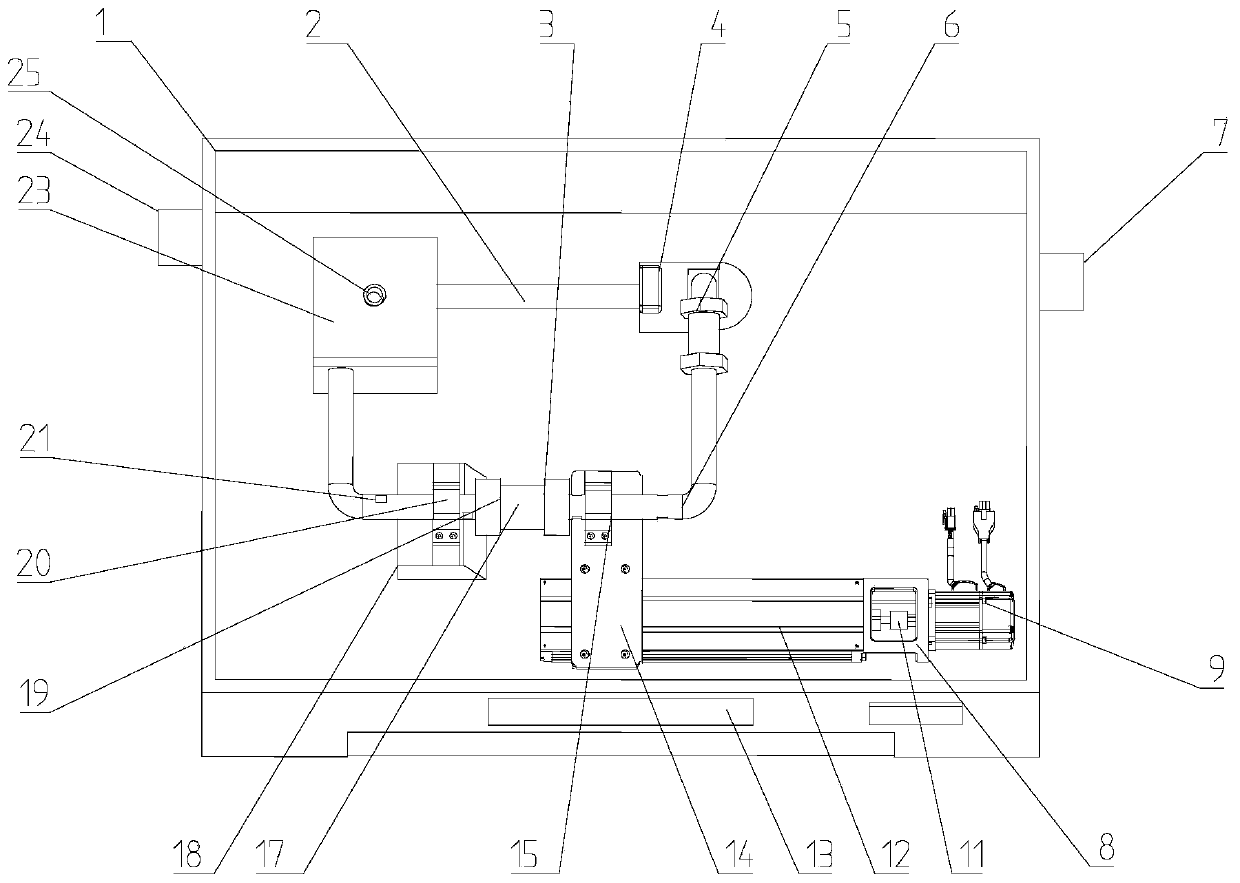

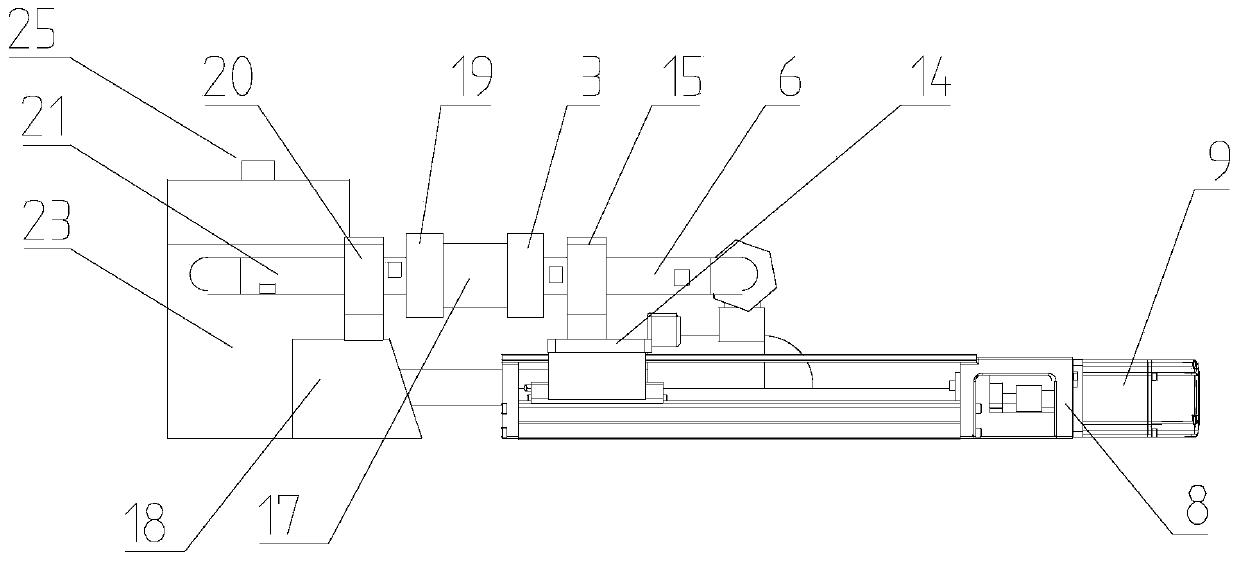

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] Such as Figure 1~3 As shown, a through-hole polishing device using negative pressure for through-hole polishing includes a sliding rail clamping assembly, a workpiece clamping assembly, an abrasive particle flow circulation assembly and a sealing device 1, the sliding rail clamping assembly, the workpiece clamping Both the holding assembly and the abrasive particle flow circulation assembly are installed inside the sealing device 1, and the sealing device 1 is provided with a nitrogen gas vent 24 and a nitrogen gas pumping port 7, and the nitrogen gas vent 24 on the sealing device 1 is connected to an external nitrogen generating device, sealed The nitrogen pumping port 7 on the device 1 is connected to an external pumping device.

[0041] The slide rail clamping assembly includes a driving motor 9, a horizontal linear module 12, a coupling 11, a motor base 8 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com