Sectioned combination-type wind-deflection-preventing composite insulating inhaul cable and installation method

A technology of composite insulation and installation method, applied in mechanical vibration damping devices, spatial arrangement/configuration of cables, etc., can solve the problems of high renovation and installation cost, inconvenient transportation, wind deflection flashover, etc., to improve the level of safe operation, avoid Wind deflection trip, the effect of ensuring insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

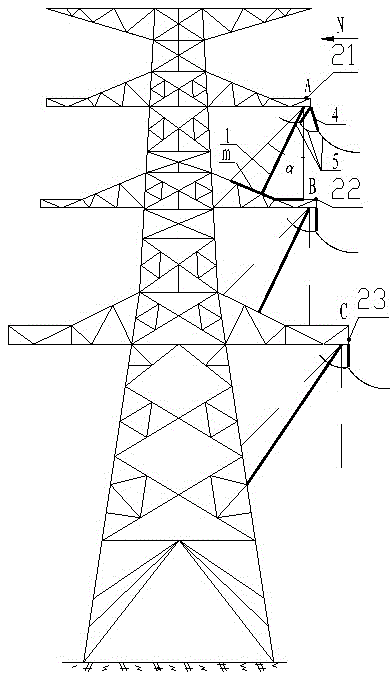

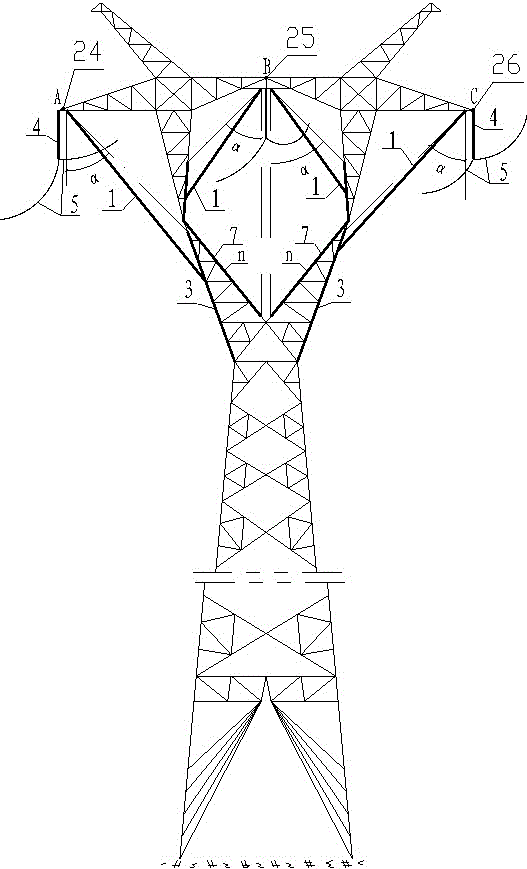

[0022] The invention is applied to high-voltage transmission lines of all voltage levels prone to wind deviation, especially to 500kV high-voltage transmission lines.

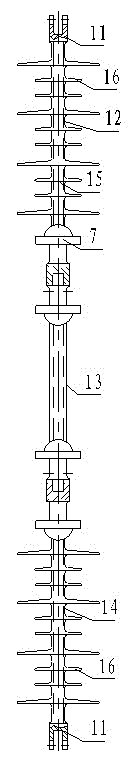

[0023] like figure 1 As shown, the cable 1 of the present invention includes a high-voltage end fitting 11, an upper rod body 12, a lower rod body 14, and an intermediate rod 13. The upper end of the upper rod body 12 and the lower end of the lower rod body 14 are respectively connected with a high-pressure end fitting 11 , the upper rod body 12 and the lower rod body 14 are connected by an intermediate rod 13, the upper rod body 12 and the lower rod body 14 all include a rod core 15 and an umbrella skirt 16 located outside the rod core 15, and the rod core 15 is epoxy resin Fiberglass drawing rod, umbrella skirt 16 is a silicone rubber composite umbrella skirt.

[0024] The high-voltage end fittings 11 are used to connect with the tower body. When connecting and installing, you only need to punch holes on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com